I-DRK255-Isixhobo soVavanyo seHotplate esiKhuselwe ukubila

Inkcazelo emfutshane:

Okokuqala, enkosi kakhulu ngokuthenga i-DRK255 Sweating Guarded Hotplate yethu, ngaphambi kofakelo kunye nokusebenzisa, nceda ufunde le ncwadana ngononophelo, enokukunceda ukuba ulungelelanise ukusebenza kwaye wenze iziphumo zovavanyo zibe lula. Ikhathalogu l Isishwankathelo 1.1 Intshayelelo emfutshane 1.2 Isicelo 1.3 Umsebenzi wesixhobo 1.4 Ukusetyenziswa kwemeko-bume 1.4.1 Ubushushu be-Ambient kunye nokufuma 1.4.2 Iimfuno zamandla 1.4.3 Akukho malunga nemithombo yokungcangcazela, njl. njl.

Okokuqala, enkosi kakhulu ngokuthenga kwethuDRK255I-Sweating Guarded Hotplate, phambi kofakelo kunye nokusebenzisa, nceda ufunde le ncwadana ngononophelo, enokukunceda ukuba ulungelelanise ukusebenza kwaye wenze iziphumo zovavanyo zichaneke lula.

Ikhathalogu

lIsishwankathelo

1.1 Intshayelelo emfutshane

1.2 Ukusetyenziswa

1.3 Umsebenzi wesixhobo

1.4 Sebenzisa okusingqongileyo

1.4.1 Ubushushu be-Ambient kunye nokufuma

1.4.2 Iimfuno zamandla

1.4.3 Akukho malunga nemithombo yokungcangcazela, njl.

1.5 Iiparamitha zobugcisa

1.6 Umgaqo-siseko Intshayelelo

1.6.1 Inkcazo kunye neyunithi yokumelana ne-thermal

1.6.2 Inkcazo kunye neyunithi yokumelana nokufuma

1.7 Ubume besixhobo

1.8 Iimpawu zesixhobo

1.8.1 Impazamo esezantsi yokuphinda-phinda

1.8.2 Ubume obubambeneyo kunye nemfezeko eyomeleleyo

1.8.3 Umboniso wexesha langempela lamaxabiso "okumelana ne-thermal kunye nokufuma".

1.8.4 Isiphumo esifaniswe kakhulu sokubila ulusu

1.8.5 Ulungelelwaniso oluzimeleyo lweengongoma ezininzi

1.8.6 Ukushisa kwe-Microclimate kunye nokufuma kuyahambelana neendawo zokulawula eziqhelekileyo

lNgaphambi kokusebenzisa

2.1 Ukwamkelwa kunye nokuhlolwa

2.2 Ukufakela

2.3 Vula amandla uze uqinisekise

lUkusebenza

3.1 Iindlela zovavanyo kunye nemigangatho

3.2 Amalungiselelo phambi kokuqala

3.3 Yenza umsebenzi wokumelana ne-thermal

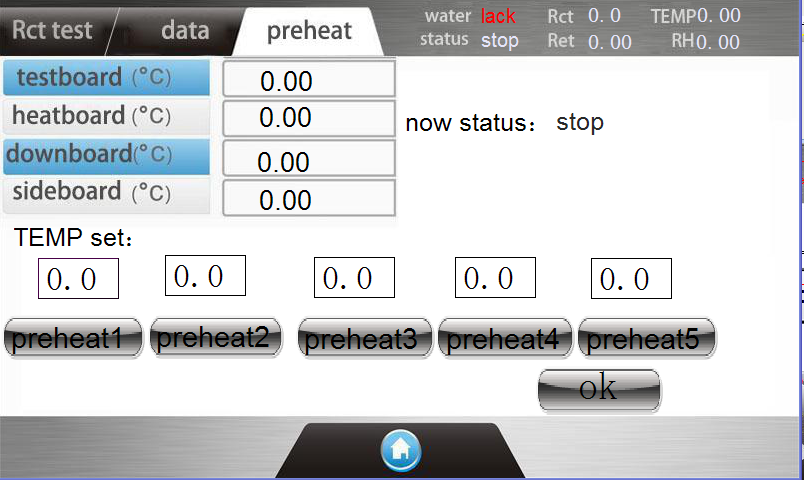

3.3.1 Ukufudumala komatshini kwangaphambili

3.3.2 Ukusetha ukuxhathisa kwe-thermal

3.3.3 Uvavanyo lwepleyiti yokumelana ne-thermal

3.3.4 Uvavanyo lokumelana nobushushu

3.3.5 Jonga, printa kwaye ucime ukuxhathisa kwe-thermal

3.3.6 Ulungelelwaniso lokumelana ne-Thermal

3.3.7 Iisampulu ezisebenzayo zokumelana ne-thermal

3.4 Yenza umsebenzi wokumelana nokufuma

3.4.1 Ukufudumala kwangaphambili koomatshini

3.4.2 Ukumiselwa kokumelana nokufuma

3.4.3 Umsebenzi wokufuma kunye nokuzaliswa kwakhona kwamanzi

3.4.4 Uvavanyo lwepleyiti yokumelana nokufuma

3.4.5 Uvavanyo lokuxhathisa ukufuma

3.4.6 Ukujonga kunye nokuprinta ukumelana nokufuma

3.4.7 Ulungelelwaniso lokumelana nokufuma

3.4.8 Iisampulu ezisebenzayo zokuxhathisa ukufuma

3.4.9 Ukuguqulwa kokumelana nokufuma kunye novavanyo lokumelana ne-thermal

lIimfuno zesampulu

4.1 Isampuli yolawulo lokufuma

4.2 Ubungakanani besampulu kunye nobukhulu

4.3 Iimfuno zokubekwa kwesampulu

lUkubaluleka kokumelana ne-thermal kunye nokufuma

5.1 Ukubaluleka kokumelana ne-thermal

5.2 Ukubaluleka kokumelana nokufuma

lUxhaso lobuchwepheshe

6.1 Ukuchongwa kweempazamo

6.2 Ugcino

lIingxaki eziqhelekileyo

7.1 Ingxaki yexesha lokubona

7.2 Ingxaki yobungakanani besampulu

7.3 Ingaba iqondo lokushisa lokusetha lihambelana nexabiso lokumelana ne-thermal

7.4 Kufunyenwe ingxaki yesalathiso

7.5 Ukulungelelaniswa kwesixhobo kunye neengxaki zesampuli eziqhelekileyo

l8. Isihlomelo: Ixesha lereferensi yovavanyo

Isishwankathelo

1.1 Isishwankathelo sencwadana

Le ncwadana ibonelela ngesicelo se-DRK255 Sweating Guarded Hotplate, imigaqo esisiseko yokufumanisa kunye neendlela ezicacileyo zokusebenzisa, inika izibonakaliso zesixhobo kunye noluhlu oluchanekileyo, kwaye ichaza ezinye iingxaki eziqhelekileyo kunye neendlela zonyango okanye iingcebiso.

1.2 Ubungakanani besicelo

I-DRK255 i-Sweating Guarded Hotplate ilungele iindidi ezahlukeneyo zamalaphu alukiweyo, kubandakanywa amalaphu emizi-mveliso, amalaphu angalukwanga kunye nezinye izinto ezahlukeneyo ezisicaba.

1.3 Umsebenzi wesixhobo

Esi sisixhobo esisetyenziselwa ukulinganisa ukuxhathisa kwe-thermal (Rct) kunye nokumelana nokufuma (Ret) kweempahla (kunye nezinye) izinto eziphathekayo. Esi sixhobo sisetyenziselwa ukuhlangabezana nemigangatho ye-ISO 11092, ASTM F 1868 kunye ne-GB/T11048-2008.

1.4 Sebenzisa okusingqongileyo

Isixhobo kufuneka sibekwe ngeqondo lobushushu obuzinzileyo kunye nokufuma, okanye kwigumbi eline-air-conditioning ngokubanzi. Ngokuqinisekileyo, kuya kuba ngcono kwiqondo lokushisa kunye negumbi lokufuma. Amacala asekhohlo nasekunene esixhobo kufuneka ashiywe ubuncinci i-50cm ukwenza umoya ungene kwaye uphume kakuhle.

1.4.1 Iqondo lobushushu lokusingqongileyo kunye nokufuma:

Ubushushu be-Ambient: 10℃ ukuya kwi-30℃; Umswakama ohambelanayo: 30% ukuya kwi-80%, ehambelana nokuzinza kweqondo lokushisa kunye nomswakama kwigumbi le-microclimate.

1.4.2 Iimfuno zamandla:

Isixhobo kufuneka sisekelwe kakuhle!

I-AC220V ± 10% 3300W 50Hz, ubuninzi ngokusebenzisa okwangoku yi-15A. Isokethi kwindawo yonikezelo lwamandla kufuneka ikwazi ukumelana ne-15A yangoku.

1.4.3Akukho mthombo we-vibration ngeenxa zonke, akukho mthombo we-corrosion, kwaye akukho mjikelezo womoya ongena ngaphakathi.

1.5 IParameter yoBugcisa

1. Uluhlu lokuvavanya ukuxhathisa kwe-thermal: 0-2000 × 10-3(m2 •K/W)

Impazamo yokuphinda ingaphantsi: ±2.5% (ulawulo lwasefektri lungaphakathi ±2.0%)

(Umgangatho ofanelekileyo ungaphakathi ±7.0%)

Isisombululo: 0.1 × 10-3(m2 •K/W)

2. Uluhlu lovavanyo lokumelana nokufuma: 0-700 (m2 •Pa / W)

Impazamo yokuphinda ingaphantsi: ±2.5% (ulawulo lwasefektri lungaphakathi ±2.0%)

(Umgangatho ofanelekileyo ungaphakathi ±7.0%)

3. Uluhlu lohlengahlengiso lobushushu lwebhodi yovavanyo: 20-40 ℃

4. Isantya somoya ngaphezu komphezulu wesampulu: Ukumiswa komgangatho 1m/s (ukulungiswa)

5. Ukuphakamisa uluhlu lweqonga (ubukhulu besampula): 0-70mm

6. Uluhlu lokumisela ixesha lokuvavanya: 0-9999s

7. Ukuchaneka kokulawula ubushushu: ±0.1℃

8. Isisombululo sesalathisi sobushushu: 0.1℃

9. Ixesha lokutshisa kwangaphambili: 6-99

10. Ubungakanani besampuli: 350mm×350mm

11. Ubungakanani bebhodi yovavanyo: 200mm × 200mm

12. Ubungakanani bangaphandle: 1050mm×1950mm×850mm (L×W×H)

13. Ubonelelo lwamandla: AC220V±10% 3300W 50Hz

1.6 Umgaqo-siseko Intshayelelo

1.6.1 Inkcazo kunye neyunithi yokumelana ne-thermal

Ukumelana ne-Thermal: ubushushu obomileyo buhamba kwindawo ethile xa i-textile ikwiqondo lokushisa elizinzileyo.

Iyunithi yokumelana ne-thermal i-Rct ikwi-Kelvin ngewathi nganye yesikwere semitha (m2·K/W).

Xa ufumanisa ukuxhathisa kwe-thermal, isampuli ihlanganiswe kwibhodi yokuvavanya ukufudumeza kombane, ibhodi yokuvavanya kunye nebhodi yokukhusela ejikelezileyo kunye neplate ephantsi igcinwe kwiqondo lokushisa elifanayo (elifana ne-35 ℃) ngokulawula ukushisa kombane, kunye nobushushu. Isivamvo sihambisa idatha kwinkqubo yolawulo ukugcina ubushushu obuthe rhoqo, ukuze ubushushu besampulu yepleyiti bubhujiswe phezulu kuphela (kwicala lesampulu), kwaye zonke ezinye izikhokelo zi-isothermal, ngaphandle kwamandla. utshintshiselwano. Kwi-15mm kumphezulu ongaphezulu kumbindi wesampulu, ubushushu bolawulo yi-20°C, ukufuma okunxulumeneyo yi-65%, kunye nesantya somoya esithe tye yi-1m/s. Xa iimeko zokuvavanya zizinzile, inkqubo iya kugqiba ngokuzenzekelayo amandla okufudumala afunekayo kwibhodi yokuvavanya ukugcina ukushisa okungapheliyo.

Ixabiso lokumelana ne-thermal lilingana nokumelana ne-thermal yesampuli (i-15mm yomoya, i-test plate, isampuli) isuse ukuchasana kwe-thermal ye-plate engenanto (i-15mm yomoya, i-test plate).

Isixhobo sibala ngokuzenzekelayo: ukumelana ne-thermal, i-coefficient yokudlulisa ukushisa, ixabiso le-Clo kunye nesantya sokugcina ukushisa

Phawula: (Ngenxa yokuba idatha yokuphindaphinda kwesixhobo ihambelana kakhulu, ukuchasana kwe-thermal yebhodi engenanto kuphela kufuneka kwenziwe kanye emva kweenyanga ezintathu okanye isiqingatha sonyaka).

Ukumelana nobushushu: Rct: (m2·K/W)

Tm —-ubushushu bebhodi yokuvavanya

Ta ——ukuvavanya ubushushu bokhuselo

A -- indawo yebhodi yokuvavanya

I-Rct0--ibhodi engenanto yokumelana ne-thermal

H —— ibhodi yokuvavanya amandla ombane

△Hc— ukulungiswa kwamandla okufudumeza

I-coefficient yokudlulisa ubushushu: U =1/ Rct(W /m2·K)

Ivala:CLO=10.155·U

Izinga logcino lobushushu: Q=Q1-Q2Q1×100%

Q1 (Akukho sampuli yokulahla ubushushu (W/℃)

Q2 (Ngesampulu yokuchitha ubushushu (W/℃)

Phawula:(Ixabiso le-Clo: kwiqondo lokushisa kwegumbi le-21 ℃, umswakama ohambelanayo ≤50%, i-airflow 10cm / s (akukho moya), umntu ovavanyayo uhlala ehleli, kunye ne-basal metabolism yi-58.15 W / m2 (50kcal / m2·h), uzive ukhululekile kwaye ugcine ubushushu obuphakathi bomzimba kwi-33℃, ixabiso le-insulation yempahla enxitywayo ngeli xesha yi-1 Clo value (1 CLO=0.155℃·m2/W)

1.6.2 Inkcazo kunye neyunithi yokumelana nokufuma

Ukumelana nokufuma: Ukuhamba kobushushu bomphunga kwindawo ethile phantsi kwemeko yoxinzelelo lomoya ozinzileyo wamanzi.

Iyunithi yokumelana nokufuma i-Ret ikwi-Pascal ngewathi nganye yesikwere semitha (m2·Pa/W).

Ipleyiti yokuvavanya kunye nepleyiti yokukhusela zombini iipleyiti ezikhethekileyo zetsimbi, ezigqunywe ngefilimu encinci (enokuthi ifake kuphela umphunga wamanzi kodwa ingabi namanzi angamanzi). Ngaphantsi kokufudumala kombane, ubushushu bamanzi adibeneyo anikezelwe yinkqubo yokubonelela ngamanzi aphakama kwixabiso elimiselweyo (elifana ne-35 ℃). Ibhodi yokuvavanya kunye nebhodi yayo yokukhusela ejikelezileyo kunye neplate ephantsi zonke zigcinwa kwiqondo lokushisa elifanayo (elifana ne-35 ° C) ngokulawulwa kokushisa kombane, kwaye inzwa yokushisa idlulisela idatha kwinkqubo yokulawula ukugcina ukushisa okungapheliyo. Ke ngoko, amandla obushushu bomphunga wamanzi ebhodi yesampulu anokuba phezulu kuphela (kwicala lesampulu). Akukho mphunga wamanzi kunye nokutshintshana kobushushu kwezinye iindawo,

ibhodi yokuvavanya kunye nebhodi yokukhusela ejikelezileyo kunye nesitya esisezantsi zonke zigcinwa kwiqondo lokushisa elifanayo (elifana ne-35 ° C) ngokufudumeza kombane, kwaye inzwa yokushisa idlulisela idatha kwinkqubo yokulawula ukugcina ukushisa okungapheliyo. Amandla obushushu bomphunga wamanzi epleyiti yesampulu anokuchithwa phezulu kuphela (kwicala lomzekelo). Akukho tshintshiselwano lwamandla obushushu bomphunga wamanzi kwamanye amacala. Iqondo lobushushu kwi-15mm ngaphezu kwesampulu ilawulwa kwi-35℃, ukufuma okunxulumeneyo yi-40%, kunye nesantya somoya oxwesileyo yi-1m/s. Umphezulu ongezantsi wefilimu unoxinzelelo lwamanzi olugcweleyo lwe-5620 Pa kwi-35 ℃, kunye nomgangatho ophezulu wesampuli unoxinzelelo lwamanzi lwe-2250 Pa kwi-35 ℃ kunye nokufuma kwe-40%. Emva kokuba iimeko zokuvavanya zizinzile, inkqubo iya kugqiba ngokuzenzekelayo amandla okufudumala afunekayo kwibhodi yokuvavanya ukugcina ukushisa okungapheliyo.

Ixabiso lokumelana nomswakama lilingana nokumelana nomswakama wesampulu (umoya we-15mm, ibhodi yokuvavanya, isampuli) thabatha ukunyanzeliswa komswakama webhodi engenanto (15mm umoya, ibhodi yokuvavanya).

Isixhobo sibala ngokuzenzekelayo: ukuxhathisa ukufuma, isalathisi sokungena komswakama, kunye nokunyameka komswakama.

Phawula: (Ngenxa yokuba idatha yokuphindaphinda kwesixhobo ihambelana kakhulu, ukuchasana kwe-thermal yebhodi engenanto kuphela kufuneka kwenziwe kanye emva kweenyanga ezintathu okanye isiqingatha sonyaka).

Ukuxhathisa ukufuma: Ret Pm——Uxinzelelo lomphunga

Pa——Uxinzelelo lomphunga wamanzi egumbi lemozulu

H——Ibhodi yovavanyo lwamandla ombane

△He—Isixa solungiso samandla ombane ebhodi yovavanyo

Isalathisi sobumanzi: imt=s*Rct/RkunyeS— 60 iphea/k

Ukungenwa kokufuma: Wd=1/(Ret*φTm) g/(m2*h*pa)

φTm-Latent ubushushu bomphunga wamanzi angaphezulu, xaTm yi35℃时,φTm=0.627 W*h/g

1.7 Ubume besixhobo

Isixhobo siqulunqwe ngamacandelo amathathu: umatshini oyintloko, inkqubo ye-microclimate, ukubonisa kunye nokulawula.

1.7.1Umzimba oyintloko uxhotyiswe ngepleyiti yesampuli, ipleyiti yokukhusela, kunye nepleyiti esezantsi. Kwaye ipleyiti nganye yokufudumeza ihlukaniswe yinto yokukhusela ukushisa ukuze kuqinisekiswe ukuba akukho kutshintshwa kobushushu phakathi komnye nomnye. Ukuze ukhusele isampuli kumoya ojikelezayo, i-microclimate cover ifakwe. Kukho umnyango weglasi obonakalayo obonakalayo phezulu, kwaye inzwa yobushushu kunye nokufuma kwegumbi lovavanyo ifakwe kwikhava.

1.7.2 Inkqubo yokubonisa kunye nokuthintela

Isixhobo samkela i-weinview touch display edibeneyo yesikrini, kwaye ilawula inkqubo ye-microclimate kunye nomqhubi wokuvavanya ukuba asebenze kwaye ayeke ngokuchukumisa amaqhosha ahambelanayo kwisikrini sokubonisa, idatha yokulawula igalelo, kunye nedatha yovavanyo lwemveliso yenkqubo yovavanyo kunye neziphumo.

1.8 Iimpawu zesixhobo

1.8.1 Impazamo esezantsi yokuphinda-phinda

Inxalenye ephambili ye-DRK255 inkqubo yokulawula ukushisa sisixhobo esikhethekileyo esiphandwe ngokuzimeleyo kwaye siphuhliswe. Ngokwethiyori, iphelisa ukungazinzi kweziphumo zovavanyo ezibangelwa yi-thermal inertia. Le teknoloji yenza impazamo yovavanyo oluphinda-phindayo ibencinci kakhulu kunemigangatho efanelekileyo ekhaya nakwamanye amazwe. Uninzi lwezixhobo zovavanyo "zokuhambisa ubushushu" zinempazamo yokuphindaphinda malunga ne-± 5%, kwaye inkampani yethu ifikelele ku-± 2%. Kunokuthiwa kusonjululwe ingxaki yehlabathi yexesha elide yeempazamo ezinkulu zokuphinda-phinda kwizixhobo zokugquma i-thermal kwaye zifikelele kwinqanaba eliphezulu lamazwe ngamazwe. .

1.8.2 Ubume obubambeneyo kunye nemfezeko eyomeleleyo

I-DRK255 sisixhobo esidibanisa umkhosi kunye ne-microclimate. Ingasetyenziswa ngokuzimeleyo ngaphandle kwezixhobo zangaphandle. Iyahambelana nokusingqongileyo kwaye iphuhliswe ngokukodwa ukunciphisa iimeko zokusetyenziswa.

1.8.3 Umboniso wexesha langempela lamaxabiso "okumelana ne-thermal kunye nokufuma".

Emva kokuba isampuli ifudunyezwe ukuya ekupheleni, yonke inkqubo "yokushisa kwe-thermal kunye nokumelana nomswakama" inkqubo yokuzinzisa ixabiso inokuboniswa ngexesha langempela. Oku kusombulula ingxaki yexesha elide lovavanyo lokumelana nobushushu kunye nokufuma kunye nokungakwazi ukuqonda yonke inkqubo.

1.8.4 Isiphumo esifaniswe kakhulu sokubila ulusu

Isixhobo sinokulinganisa okuphezulu kwesikhumba somntu (efihliweyo) isiphumo sokubila, esahlukileyo kwibhodi yokuvavanya enemingxuma encinci kuphela. Iyanelisa uxinzelelo olulinganayo lomphunga wamanzi kuyo yonke indawo kwibhodi yokuvavanya, kwaye indawo yokuvavanya esebenzayo ichanekile, ukwenzela ukuba umlinganiselo "wokumelana nomswakama" usondele kwixabiso langempela.

1.8.5 Ulungelelwaniso oluzimeleyo lweengongoma ezininzi

Ngenxa yoluhlu olukhulu lovavanyo lokumelana ne-thermal kunye nomswakama, i-multi-point calibration ezimeleyo inokuphucula ngokufanelekileyo impazamo ebangelwa ukungahambi kakuhle kunye nokuqinisekisa ukuchaneka kovavanyo.

1.8.6 Ukushisa kwe-Microclimate kunye nokufuma kuyahambelana neendawo zokulawula eziqhelekileyo

Xa kuthelekiswa nezixhobo ezifanayo, ukwamkela ukushisa kwe-microclimate kunye nomswakama ohambelana nomgangatho wokulawula umgangatho uhambelana ngakumbi "nomgangatho wendlela", kwaye iimfuno zokulawula i-microclimate ziphezulu.

Ngaphambi kokusebenzisa

Inkcazo yomxholo kweli candelo ibandakanya isishwankathelo sokuqala esikhawulezayo ukukunceda uqonde ngokukhawuleza. Oku kuya kukukhokela ngokuseta, ulungelelwaniso kunye nokusebenza okusisiseko kwesixhobo. Kucetyiswa ukuba uqale ukufunda le nxalenye emva kokukhangela umxholo wangaphambili.

2.1 Ukwamkelwa kunye nokuhlolwa

Vula ibhokisi kwaye ukhuphe umatshini wonke ukujonga umonakalo ocacileyo.

Bala ngokoluhlu lokupakisha, imiyalelo yokusebenza kunye nezincedisi.

2.2 Ukufakela

2.2.1Lungisa iinyawo ezine kwiziko leqamza elakhelwe ngaphakathi elithe tye ukuqinisekisa umgangatho webhodi yovavanyo.

2.2.2 Iintambo

Qhagamshela enye isiphelo sentambo yekhompyuter kwisokethi yekhompyuter yesixhobo kunye nesiphelo esinye kwikhompyuter (ukhetho)

2.3 Vula amandla uze uqinisekise

Layita amandla kwaye ujonge ukuba isiboniso siqhelekile na.

Ukusebenza

3.1 Iindlela zovavanyo kunye nemigangatho

ISO 11092, ASTM F 1868, GB/T11048-2008

3.2 Amalungiselelo phambi kokuqala

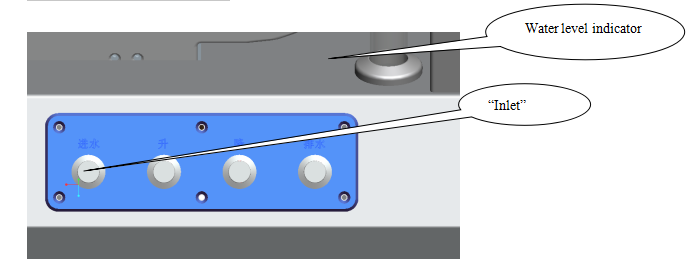

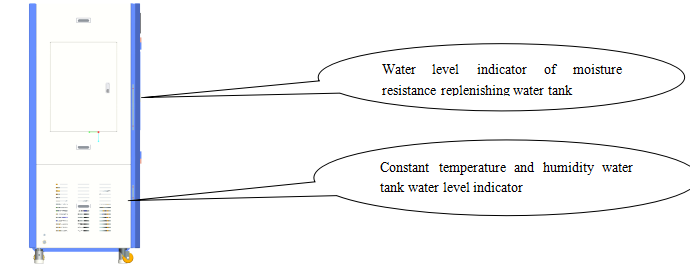

3.2.1Ngaphambi kokuba uqalise umatshini, khangela ukuba kukho amanzi aneleyo kwisalathisi somgangatho wamanzi weqondo lokushisa rhoqo kunye netanki yamanzi yokufuma. Ukuba akukho manzi, nceda wongeze amanzi kuqala. Ngaphandle koko, nangona ivuliwe, ukushisa okungapheliyo kunye nokufuma akuyi kusebenza. Indlela yokongeza amanzi: Vula umnyango wangaphambili, ukhulule isigqubuthelo sensimbi engenasici ngakwesobunxele, thatha i-funnel ye-accessory, kwaye uthele amanzi amaminerali (amanzi adibeneyo acetyiswayo) ukubonelela ukulungiswa kwe-microclimate humidity. Galela amanzi phakathi kwemigca yesalathisi somgangatho wamanzi.

3.2.2Nceda uqinisekise ukuba kukho amanzi kwisalathisi somgangatho wamanzi wokuxhathisa ukufuma okuzalisa itanki yamanzi kwicala eliphezulu lasekhohlo, kwaye ke unikeze uvavanyo lokumelana nokufuma. Indlela yokusebenza: bhekisa kumba 3.4.3 [Ukusebenza kokufumisa kunye nokuzaliswa kwakhona kunye nokusebenza kovavanyo lokubeka ifilim]Phawula:Le tanki yamanzi kufuneka izaliswe ngamanzi adibeneyo.

3.2.3 Intshayelelo yephepha kunye nokusetwa kweparamitha

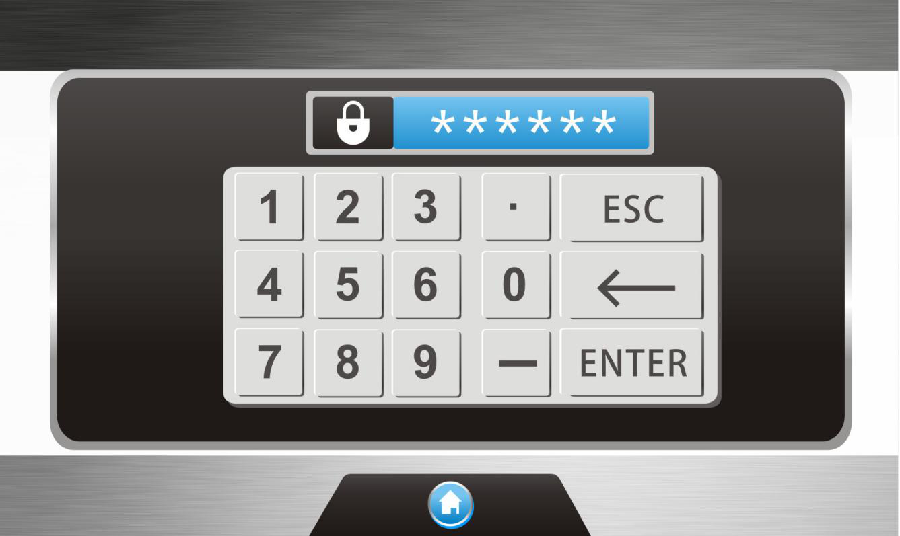

Ukusetwa rhoqo kobushushu kunye nokufuma; emva kokuvula amandla, ujongano lokungena lulandelayo luyaboniswa:

Cofa iqhosha elithi "Ngena" ukufaka igama lokugqitha

Emva kokufaka okuchanekileyo, kuya kubonisa:

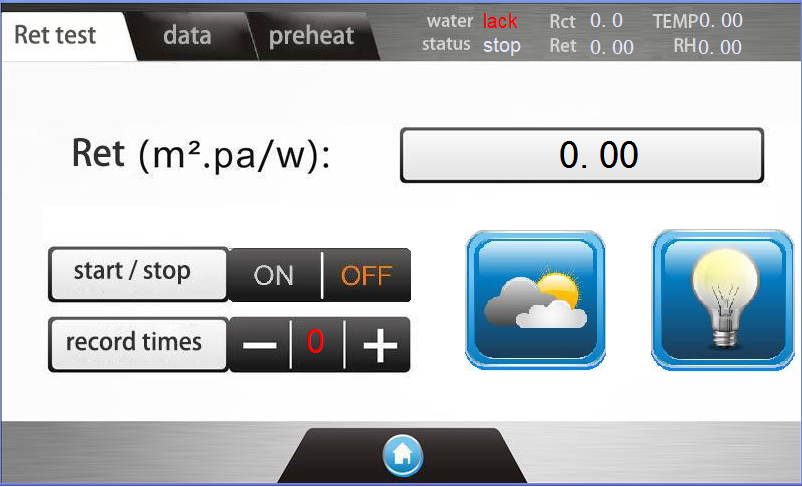

Ujongano oluphambili lunezinto ezi-4: uvavanyo, isethi, ichanekile kunye nedatha.

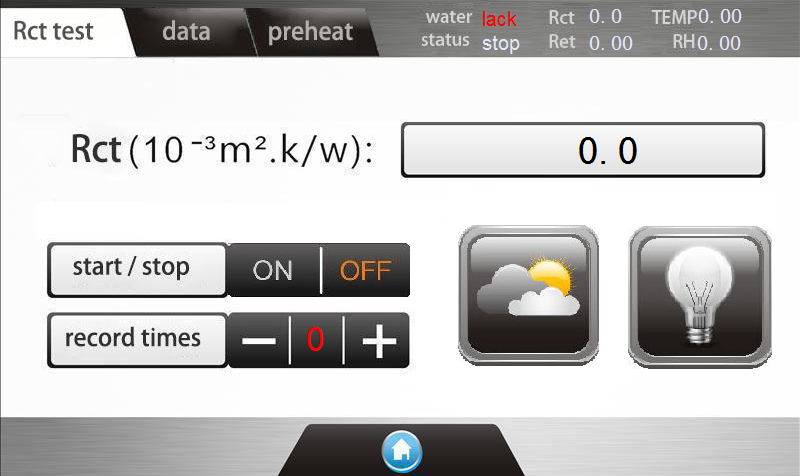

Uvavanyo: I-interface yovavanyo isetyenziselwa ukungena kwi-thermal resistance okanye i-experimenti yokumelana nokufuma, kunye nokuvula okanye ukucima inkqubo yefriji kunye nokukhanyisa.

Cinezela iqhosha lokulawula ifriji kwi-Figure 305-1 ukuvula okanye ukucima ifriji kwaye uqale ubushushu obuqhubekayo kunye nenkqubo yomswakama kunye nokulawula ukukhanya; Umzobo we-305-2 izixhobo zedatha yokusebenza ngexesha langempela; Umzobo 305-3 ngumsebenzi wokushisa umatshini obandayo;

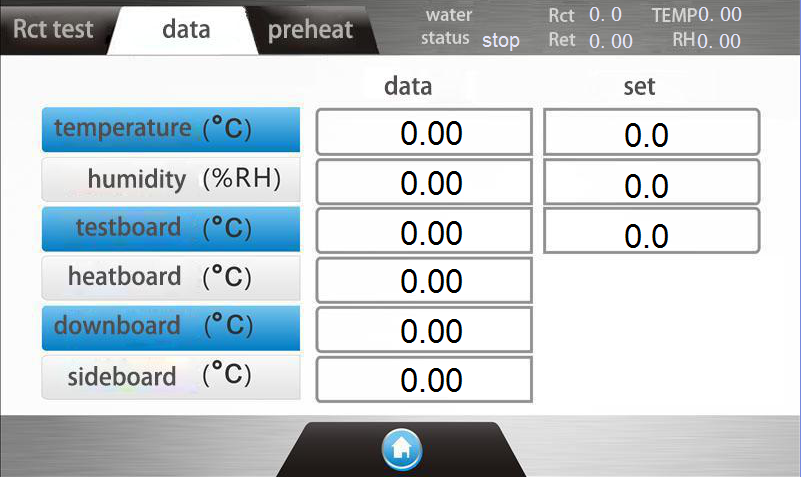

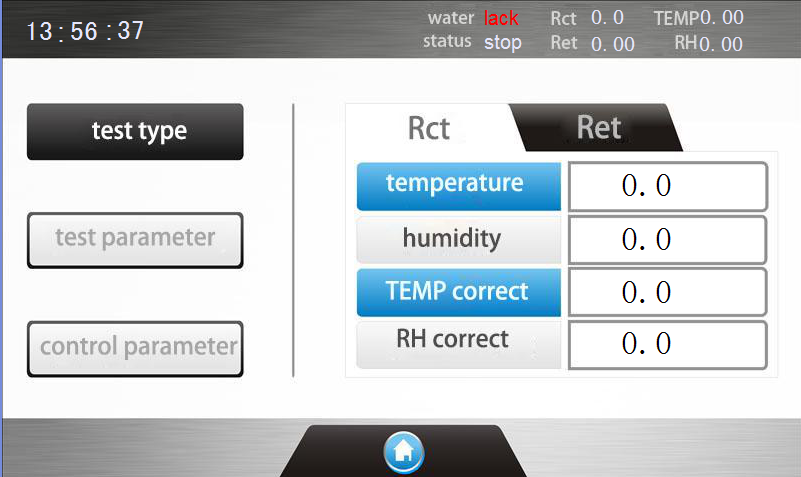

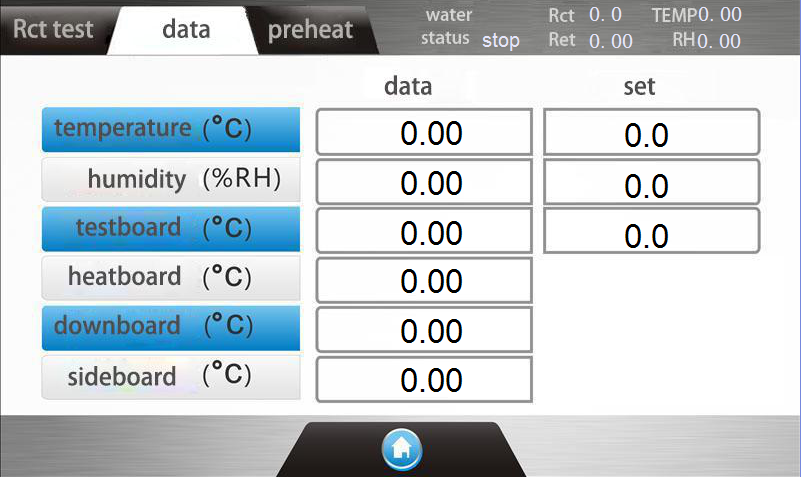

Ukumisela: isetyenziselwa ukuseta iiparamitha zovavanyo kunye neqondo lobushushu kunye nokufuma kweeparamitha zokusingqongileyo zemozulu

Imilinganiselo yeparamitha yobushushu kunye nokufuma:

Xa ukhetha ukumelana ne-thermal, inkqubo iya kumisa ngokuzenzekelayo ukushisa kwe-microclimate kwi-20 ℃ kunye nomswakama kwi-65%;

Xa ukhetha ukumelana nomswakama, inkqubo iya kubeka ngokuzenzekelayo ukushisa kwe-microclimate kwi-35 ° C kunye nomswakama kwi-40%;

Abasebenzisi banokuseta ezinye iiparamitha zobushushu kunye nokufuma ngokweemeko zokwenyani.

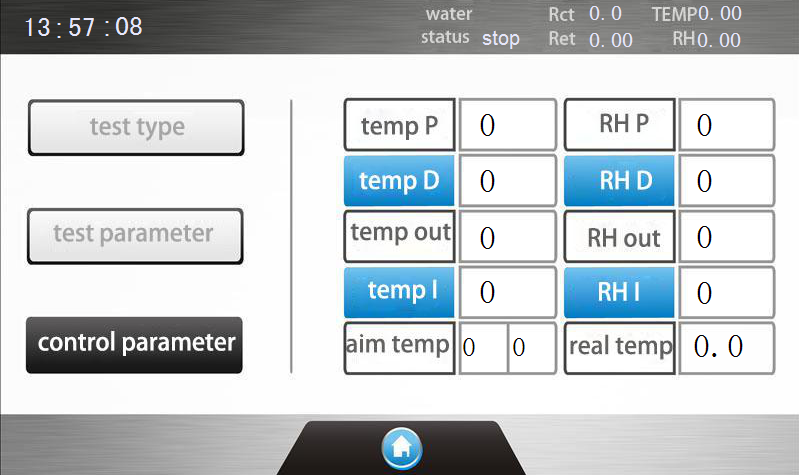

Imilinganiselo yolawulo lobushushu kunye nokufuma kweparamitha kwindawo yokugcina impahla:

I-interface yokucwangcisa iparameter yokulawula ubushushu kunye nomswakama, le nxalenye yeparameter imiselwe ngaphambi kokushiya imveliso, umsebenzisi ngokuqhelekileyo akadingeki ukuba abeke le nto, ukuba kuyimfuneko, ingcali yefektri inokuyibeka.

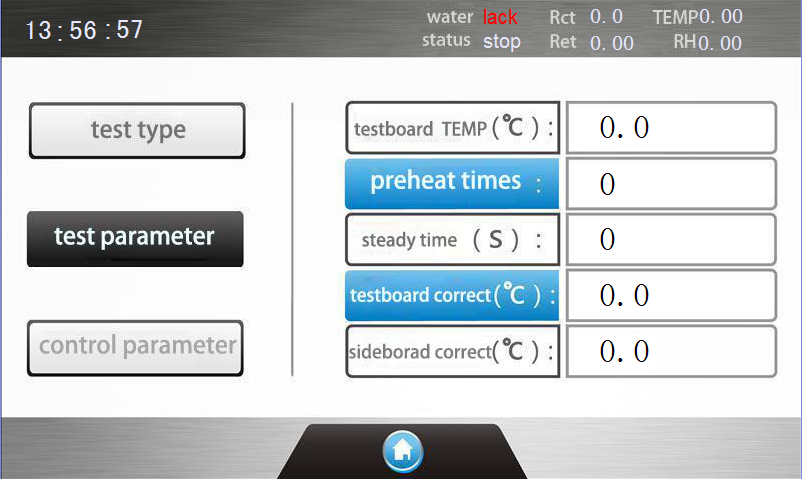

Ukusetwa kweparamitha yokumelana nobushushu kunye nokufuma:

Ngokomgangatho, ubushushu bebhodi yovavanyo lusetelwe kuma-35 ℃, umjikelo wokufudumeza ngokuqhelekileyo ngamaxesha angama-6, kwaye ixesha lovavanyo yimizuzwana engama-600 (oku kuseto olumiselweyo oluqhelekileyo, njengovavanyo lokuqala lwesampulu okanye uvavanyo lwesampulu etyebileyo.

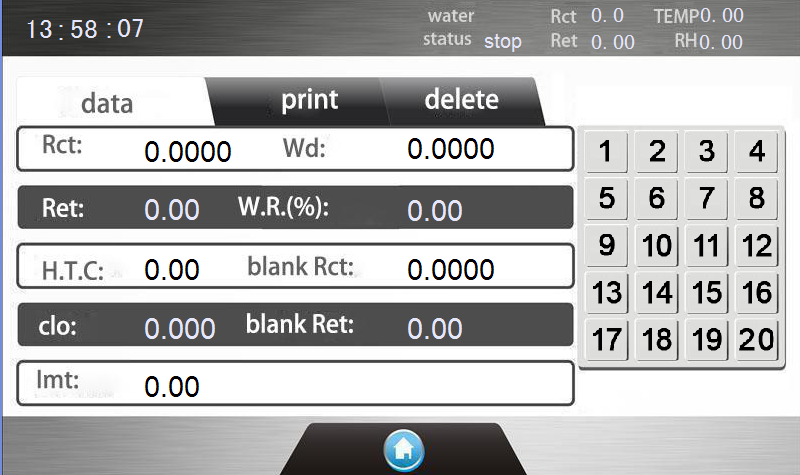

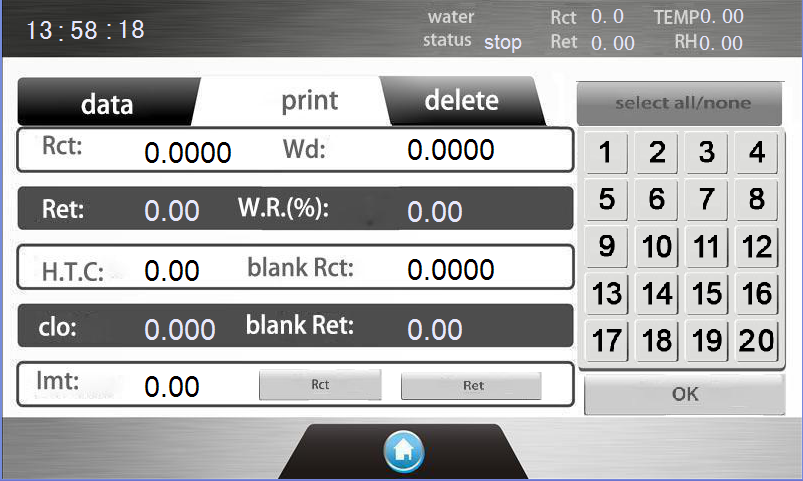

Shicilela: isetyenziselwa ukubuza kunye nokuprinta idatha, kunye nokucima iirekhodi

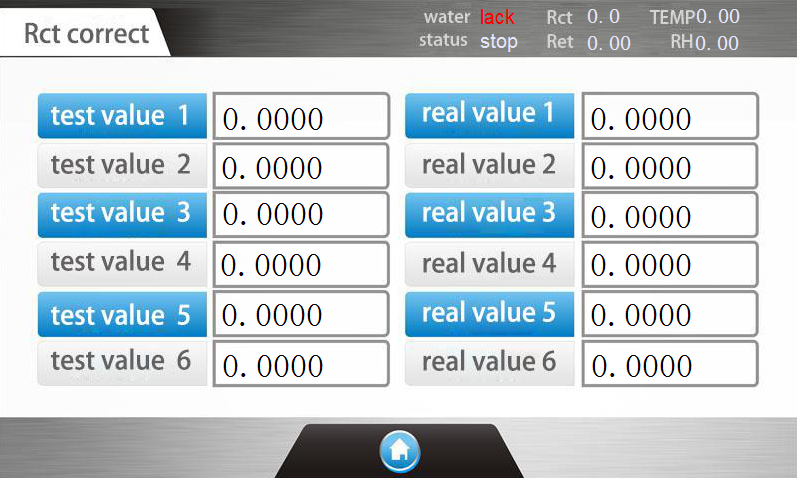

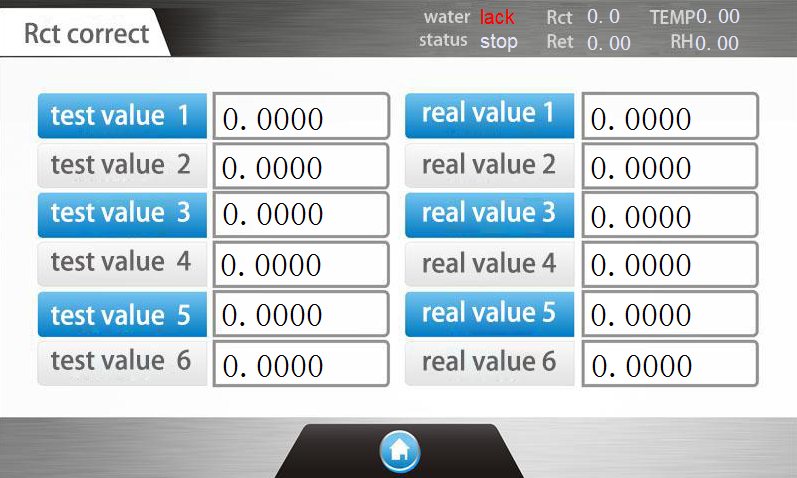

I-Rct Echanekileyo: isetyenziselwa ukulinganisa idatha yokumelana ne-thermal

3.3 Yenza umsebenzi wokumelana ne-thermal

Okokuqala khangela ukuba ibhodi yovavanyo yomile ngokupheleleyo (ukuba imanzi, nceda ubhekisele kwi-3.4.9 yokusebenza).

3.3.1 Ukufudumala komatshini kwangaphambili

Emva kokukhanyisa umbane, umatshini wonke kufuneka ufudunyezwe malunga nemizuzu engama-45, apho ilaphu eliphakathi libekwe kwipleyiti enemingxuma. Xa iplate yokuvavanya ifikelela kuma-35 ° C, indwangu ithathwa ngaphandle, kwaye ke ukushisa kwesitya sokufudumeza kunye nesitya esisezantsi sibonwa ukufikelela malunga ne-35.2 ukugqiba ukupholisa. Emva kokuba umatshini ushushu, isampuli yokuvavanya (okanye isampuli eqhelekileyo) ingafakwa kwibhentshi yokuvavanya.

3.3.2 Isetingi yokumelana nobushushu Jonga uMfanekiso 309

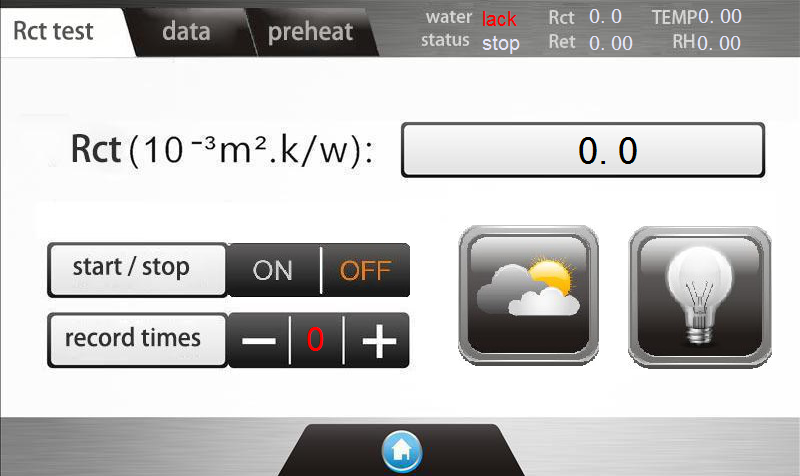

Cwangcisa iparameters kwi parameter setting kwaye ucinezele "Test" ukufaka uvavanyo "thermal resistanc"

Ujongano lovavanyo lubonisa njengoko kubonisiwe kuMfanekiso 314:

3.3.3 Uvavanyo lwepleyiti yokumelana ne-thermal

Ngaphambi kovavanyo, kufuneka "kungabikho sampuli yokuxhathisa i-thermal"- ipleyiti engenanto yokumelana ne-thermal.

Ukuxhatshazwa kwe-thermal ye-plate engenanto kukuxhathisa kwe-thermal yesixhobo ngokwawo ngaphandle kwesampuli.

Kwi-interface ye "thermal resistance operation", khetha "amaxesha okuvavanya" ukuya ku-0 kwaye ucinezele "ukuqala" ukwenza "uvavanyo lweplate engenanto yokumelana ne-thermal". Ukulandelelana kovavanyo: i-preheat-stable-test-stop (fumana ukuxhathisa kwe-thermal yebhodi engenanto kwaye uyigcine ngokuzenzekelayo)

Phawula:"Ibhodi engenanto ye-thermal resistance" iyacetyiswa ukuba yenziwe kanye ngoMatshi ukuya kuJuni. Ngenxa yokuba impazamo yokuphindaphinda yovavanyo lwebhodi engenanto yesi sixhobo incinci kakhulu, akufuneki ukuqalisa ibhodi engenanto yokumelana ne-thermal yonke imihla.

3.3.4 Uvavanyo lokumelana nobushushu

Kwi-interface "ye-thermal resistance operation".

Emva kokuhlangabezana nesicelo se-3.3.1, faka isampuli kumphezulu wepleyiti enemingxuma, lungisa iqhosha elithi "phezulu naphantsi" phambi kwebhentshi yokuvavanya ngaphakathi kwegumbi lokuvavanya, kwaye ugubungele amacala amane omnini wesinyithi, xa isibambi sesinyithi sikwindawo ethe tye. Beka phantsi ikhava ye-plexiglass, vala umnyango wesixhobo, cofa iqhosha elithi "qalisa", kwaye isixhobo siya kuqhuba ngokuzenzekelayo.

Ukulandelelana okusebenzayo: i-preheat-stable-test-stop, bonisa ukuchasana kwe-thermal yokuqala kunye nezinye izibonakaliso.

Phawula:Emva kokubonisa "izinzile", ukuba umsebenzisi ucinga ukuba idatha ithembekile kwaye ayifuni ukuqhubeka nokuvavanya, unokucofa iqhosha elithi "stop", kwaye isixhobo siya kugcina ixabiso lokumelana ne-thermal elibonakalisiweyo njengesiphumo sovavanyo.

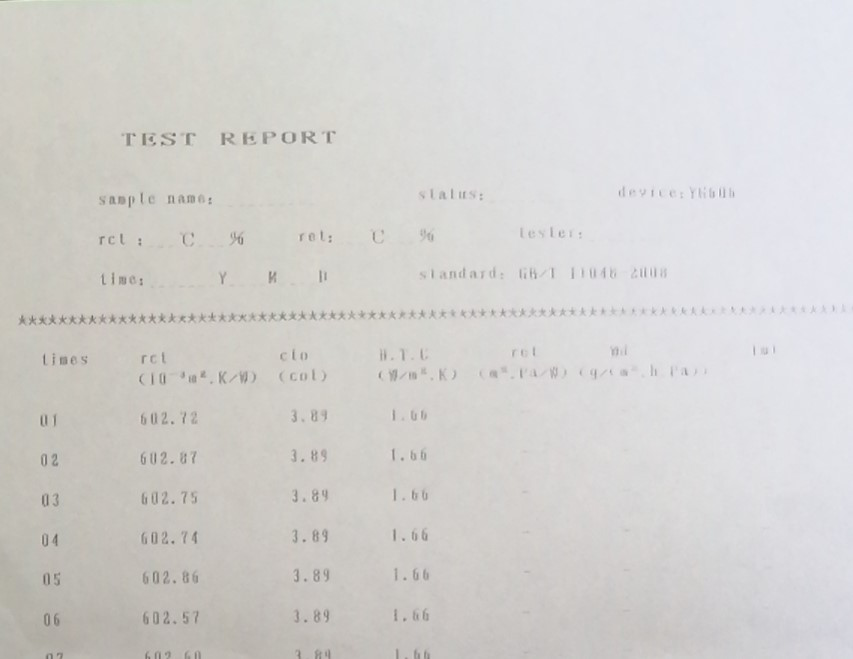

Guqula isampuli, cinezela i-2 "ngamaxesha erekhodi" ukuvavanya isampuli yesibini, njalo njalo. Ingxelo yovavanyo inokuprintwa emva kweemvavanyo ezi-3 ngokwendlela yomgangatho.

3.3.5 Jonga, printa kwaye ucime ukuxhathisa kwe-thermal

Cinezela "Shicilela" ukubonisa "Umbuzo weDatha kunye noShicilelo" ujongano, njengoko kubonisiwe kuMfanekiso 317.

Cinezela iqhosha elithi "Kulungile" kwakhona, kwaye isixhobo siya kuprinta ngokuzenzekelayo ingxelo yovavanyo lokumelana ne-thermal, njengoko kubonisiwe kuMfanekiso 318.

Tshintshela kwi-interface yokucima, khetha irekhodi eliza kucinywa, uze ucinezele "Kulungile", idatha yovavanyo ekhethiweyo ngoku iya kususwa, kwaye indawo yayo iya kutshintshwa yidatha yovavanyo olulandelayo.

3.3.6 Ulungelelwaniso lokumelana ne-Thermal

Kunconywa ukwenza oku xa umatshini omtsha, okanye ulinganiswe kanye emva kweenyanga ezintandathu, kwaye xa ixabiso lingaqhelekanga.

3.3.6.1 Beka isampuli esemgangathweni yesiponji (isampulu eqhelekileyo enexabiso eliqhelekileyo lokumelana ne-thermal) enikezelwe kwizixhobo zesixhobo kwibhentshi yovavanyo.

3.3.6.2 Qwalasela iziphumo zovavanyo kunye neziphumo eziqhelekileyo phantsi kwephepha lokulinganisa ukuxhathisa kwe-thermal ukuqinisekisa ukuba yonke idatha ayiziro.

3.3.6.3 Kwi-interface yovavanyo lokumelana ne-thermal, khetha "ixesha lokurekhoda 1" kwaye ucinezele iqhosha elithi "Qala".Phawula:Kananjalo kufuneka udibane negatya elithi 3.3.1 phambi kokuba ucofe iqhosha elithi “Qala”.

Ngethuba lovavanyo lokumelana ne-thermal, ikona eliphezulu lasekunene lephepha elifanayo libonisa kuqala "Preheat", "Stable", "Test", "Stop", kunye "nerekhodi ixesha le-1", ukuphela kovavanyo.

3.3.6.4 Emva koko faka iisampuli eziqhelekileyo zesipontshi zezinye ubukhulu, kwaye ulinganise iziphumo zovavanyo "zexesha lerekhodi 12" kunye "nexesha lokurekhoda 3" njengoko ku-3.3.6.1 ukuya ku-3.3.6.3.

3.3.6.5 Faka ixabiso elilinganisiweyo lokumelana ne-thermal yeesampuli eziqhelekileyo zesipontshi zobunzima obuhlukeneyo kwizinto ezihambelanayo "IziPhumo zoVavanyo", kwaye ufake "imilinganiselo yedatha yedatha" kwiisampuli ezisemgangathweni ezihambelanayo kwizinto ezihambelanayo "Isiphumo esiPhambili" .

Umsebenzisi unokukhetha kuphela umgangatho omnye okanye emibini yobukhulu bokulinganisa, kunye negalelo elithi "0" kwabanye. Qaphela: Kwi-interface ye-"Thermal Resistance Calibration", faka isiponji esilinganiselweyo sedatha yesampuli ukusuka kwencinci ukuya kwenkulu ngokolandelelwano lweziphumo zovavanyo 1, 2, 3, kunye neziphumo eziqhelekileyo 1, 2, 3.

Cinezela "Buyisa" ukuphuma kujongano kwaye ulungelelwaniso lugqityiwe.

Qaphela: Musa ukutshintsha idatha kumlinganiselo wokumelana ne-thermal ngokulula ngamaxesha aqhelekileyo. Kungcono ukugcina ikopi kwezinye iindawo ukunqanda ukulahlekelwa yidatha yokulinganisa.

Umsebenzisi unokukhetha kuphela umgangatho omnye okanye emibini yobukhulu bokulinganisa, kunye negalelo elithi "0" kwabanye.Phawula:Kwi-interface ye-"Thermal Resistance Calibration", faka idatha yesampula yesiponji esilinganisiweyo ukusuka kwincinci ukuya enkulu ngokulandelelana kweziphumo zovavanyo 1, 2, 3, kunye neziphumo eziqhelekileyo 1, 2, 3.

Cinezela "Buyela" ukuphuma kwi-interface kwaye ulungelelwaniso lugqityiwe.

Phawula:Musa ukutshintsha idatha kwi-calibration ye-thermal resistance calibration ngokulula ngamaxesha aqhelekileyo. Kungcono ukugcina ikopi kwezinye iindawo ukunqanda ukulahlekelwa yidatha yokulinganisa.

3.3.7 Iisampulu ezisebenzayo zokumelana ne-thermal

Esi sixhobo asiphelelanga ekuboneni ukuxhathisa kwe-thermal ye-textiles, kwaye ingasetyenziselwa ukufunyanwa kwe-thermal ukumelana nezixhobo ezahlukeneyo zeplate.

3.4 Yenza umsebenzi wokumelana nokufuma

3.4.1 Ukufudumala kwangaphambili koomatshini

Emva kokukhanyisa umbane, umatshini wonke kufuneka ufudunyezwe malunga nemizuzu engama-60. Ngeli xesha, kufuneka kuqinisekiswe ukuba i-3.4.3 i-humidification kunye nokusebenza ngokutsha kwamanzi kunye nokusebenza kokufakwa kwefilimu yokuvavanya kugqityiwe. Beka ilaphu elinobutyebe obuphakathi kwipleyiti enemingxuma, kwaye ukhuphe ilaphu xa ipleyiti yovavanyo ifikelela kwi-35℃, kwaye ke ujonge ubushushu bepleyiti yokufudumeza kunye nobushushu bepleyiti esezantsi ukuya malunga ne-35.2, gqibezela ubushushu bomatshini obandayo, ungabeka isampuli yovavanyo kwibhentshi yovavanyo.

3.4.2Ukufumaukusetwa kokumelana

Cinezela iqhosha elithi "Useto", kwaye ucinezele "Ukushisa kunye nokuThuthuka kweParameter yokuSeta" ukubonisa i-interface ye-309.

3.4.3 Umsebenzi wokufuma kunye nokuzaliswa kwakhona kwamanzi

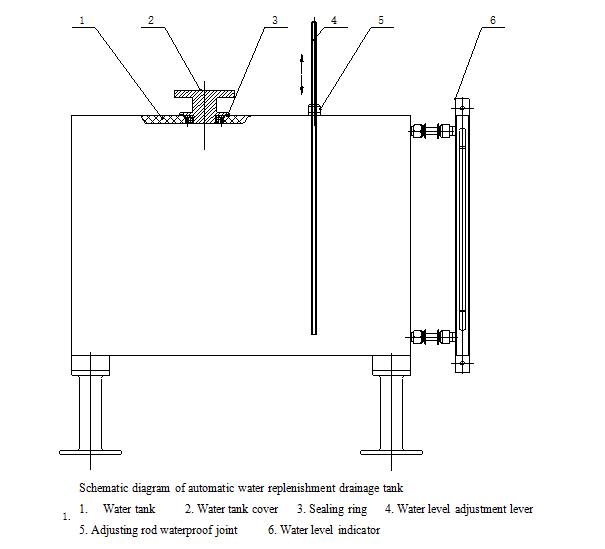

Jonga ukuba akhona na amanzi kwitanki yokuzalisa amanzi. Ukuba akukho manzi, vula ucango oluncinci kwicala lasekhohlo lesixhobo, khulula isigqubuthelo setanki yamanzi 2, emva koko ufake isalathisi somgangatho wamanzi intonga yesi-4 kumzantsi wetanki yamanzi kwaye uqinise intonga yokulungelelanisa i-nut 5, kwaye uthathe. ifaneli evela kwizincedisi, Emva koko ugaleledistilledamanzi emlonyeni wetanki yamanzi, yenza umgangatho wamanzi phakathi kwemigca ebomvu yesalathisi senqanaba lamanzi 6, uze uqinise isivalo setanki yamanzi.

Cinezela iqhosha elithi "I-Water Inlet" eboniswe kuMzobo 323, khulula umdibaniso ongenamanzi wentonga yokulungelelanisa, kwaye ngokukhawuleza ukhuphe intonga yokulungelelanisa umgangatho wamanzi. Amanzi kwitanki yokuzalisa kwakhona aya kuqukuqela ngokuzenzekelayo kumzimba wovavanyo. Qwalasela isalathisi somgangatho wamanzi kwicala lasekunene lebhentshi yovavanyo kunye novavanyo Ukuba ubamba umphezulu weplate ye-porous ngesandla sakho, xa umswakama uphuma, unokumisa i-lever yokulungiswa komgangatho wamanzi ukutsala phezulu, kwaye uqinise umdibaniso ongenamanzi. .

Ukubekwa kwefilimu yovavanyo: Thatha ifilimu yovavanyo kwi-attachment, krazula ifilimu ekhuselayo, kwaye usebenzise i-elastic enye yokuvavanya. Yisasaze phezu kweplate ye-porous. Thatha ibhloko yekotoni kwisinamathiselo ukuze ululaze ifilimu kwaye ululaze ifilimu. Susa amaqamza omoya phakathi kwamacwecwe, kwaye emva koko uthathe umtya werabha kwi-attachment, kwaye ulungise ifilimu kumzimba wovavanyo kwicala elijikelezayo.

3.4.4 Uvavanyo lwepleyiti yokumelana nokufuma

Phambi kokuba isixhobo sibhaqe isampuli, kufuneka kubekho “ukumelana nesampulu yokufuma”-ibhodi engenanto yokumelana nokumanzi.

Ukumelana nokufuma kwepleyiti engenanto ibhekisela ekuxhathiseni umswakama wesixhobo ngokwawo xa kukho ifilimu kuphela.

Khetha "ixesha lerekhodi 0" kwaye ucinezele "Qala" ukwenza uvavanyo "lokumelana nokufuma kwebhodi engenanto".

Inkqubo yovavanyo lokumelana nokufuma: i-preheat-stable-test-stop (fumana ukuxhathisa kokufuma kwebhodi engenanto kwaye uyigcine ngokuzenzekelayo)

3.4.5 Uvavanyo lokuxhathisa ukufuma

Kwi-interface yokusebenza yokumelana nokufuma (inokuqhutywa emva kokuba ubushushu bamacwecwe amathathu bufikelele kwigatya le-3.4.1)

Khetha u-1 ngexesha lerekhodi (okt, isampuli 1).

Emva kokuba isixhobo sihlangabezane neemfuno ze-3.4.1, faka isampuli yokuvavanya kwindawo ephezulu yefilimu, cinezela iqhosha elithi "phezulu, phantsi", kwaye ugubungele amacala amane entsimbi yentsimbi. Xa intsimbi yentsimbi ikwimo ethe tye, beka phantsi isigqubuthelo seplexiglass. Vala umnyango wesixhobo kwaye ucinezele iqhosha elithi "Qala". Isixhobo siya kuqhuba ngokuzenzekelayo. Ulandelelwano oluqhubayo kukuba: ukufudumala-uzinzo-ukuvavanya-ukuyeka, kwaye ubonise ukuxhathisa kokuqala komswakama kunye nezinye izibonakaliso.

Guqula isampuli; cinezela i-2 ngexesha lokurekhoda ukuvavanya isampuli yesibini, indlela iyafana nalapha ngasentla, njalo njalo. Ingxelo yovavanyo lokumelana nokufuma inokuprintwa emva kweemvavanyo ezi-3 ngokwendlela yomgangatho.

3.4.6 Ukujonga kunye nokuprinta ukumelana nokufuma

Ukumelana nokufuma kufuneka kulinganiswe. Amanyathelo afana ne-thermal resistance calibratuion.

3.4.7 Iisampulu ezisebenzayo zokuxhathisa ukufuma

Esi sixhobo asiphelelanga ekubhaqweni kokumelana nokufuma kwezinto ezilukiweyo, kukwafanelekile ukubhaqwa kokumelana nokufuma kwezixhobo ezahlukeneyo zepleyiti, kodwa akunantsingiselo ukufumanisa ukuxhathisa ukufuma kwezinto ezinganyangekiyo, kuba ixabiso lokumelana nokufuma alinasiphelo.

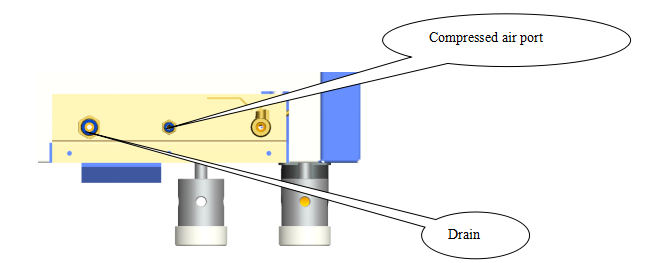

3.4.8Ukuguqulwa kokumelana nokufuma kunye novavanyo lokumelana ne-thermal

Kwicala lasekhohlo lesixhobo, njengoko kubonisiwe kuMzobo 327, qhagamshela umoya ocinezelweyo, faka i-pan yokucoca phantsi kombhobho, uze ucinezele iqhosha elithi "Drain" ngaphakathi kwegumbi lokuvavanya njengoko kuboniswe kuMzobo 317, cinezela ngokubanzi i-6 malunga ne-8. amaxesha (ngexesha elinye emva kokuva "cofa"), amanzi aya kukhutshwa ngokuzenzekelayo, kwaye emva koko usete ubushushu bebhodi yovavanyo ukuya kwi-40 ℃, kwaye iqhube iyure enye (emva koko, ukuba ibhodi yokuvavanya kunye nebhodi yokukhusela isekho Ukuba kukho umswakama, ixesha linokwandiswa ngokufanelekileyo). Xa usenza lo msebenzi, akufuneki kubekho isampulu okanye ifilimu yovavanyo lokumelana nokufuma kwindawo yovavanyo.

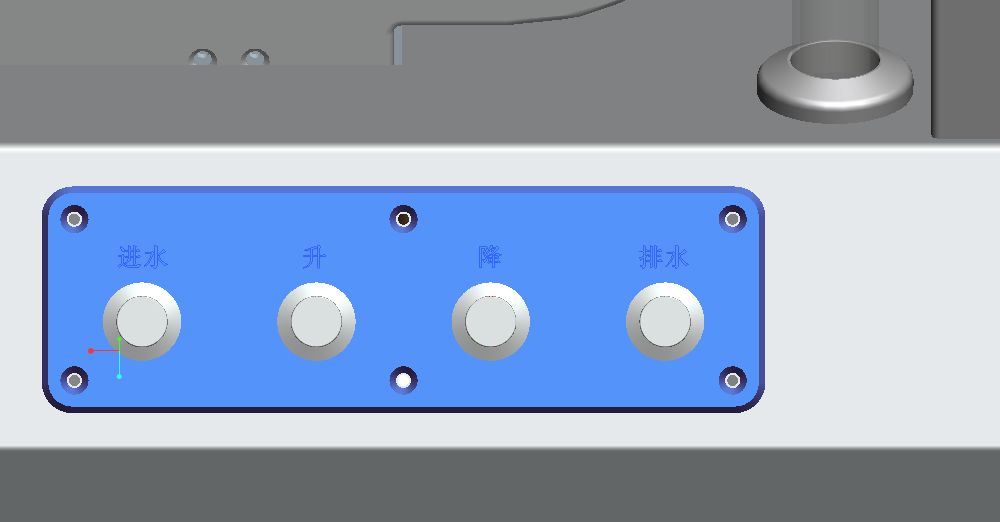

lIzibuko lomoya elicinezelweyo

4.1 Isampuli yokulawula ukufuma: iisampuli kunye neesampuli zovavanyo kufuneka zibekwe phantsi kweemeko ezichaziweyo ze-atmospheric zokulawula ukufuma kwiiyure ezingama-24.

4.2 Ubungakanani besampuli kunye nobukhulu: Thatha iisampulu ezintathu kwisampuli nganye, ubungakanani besampuli yi-35 × 35cm, kwaye isampuli kufuneka ibe tyaba kwaye ingabi nemibimbi.

4.3 Iimfuno zokubekwa kwesampulu: Icala langaphambili lesampulu libekwe mcaba kwibhodi yovavanyo, kwaye onke amacala ebhodi yovavanyo agqunyiwe.

lUkubaluleka kokumelana ne-thermal kunye nokufuma

5.1Ukuxhatshazwa kwe-thermal yimpawu yokusebenza kokutshintshwa kobushushu bezinto eziphathekayo. Sesinye sezona zalathisi ezisisiseko zovavanyo lwelaphu. Ngenxa yemisebenzi emithathu esisiseko yempahla (ukugcina ukufudumala, ukukhuselwa komzimba kunye nokuzibonakalisa), eyona nto ibalulekileyo kukufudumala. Ukuba akukho mpahla namhlanje Ukukhuselwa kwabantu abanakuphila. Okwesibini, imimandla eyahlukeneyo kunye namaxesha onyaka aneemfuno ezahlukeneyo zobushushu. Ukuxhatshazwa kwe-thermal kunokubonelela ngesiseko sokuba abantu bakhethe ukuba luhlobo luni lwelaphu, olubonisa ukubaluleka kokufumanisa ukuchasana kwe-thermal.

5.2Ukuchasana kobumanzi luphawu olubonisa amandla ezinto zokuhambisa umswakama. Ngokuphuculwa kwemigangatho yokuphila kwabantu, iimfuno eziphezulu zibekwe phambili zokugqoka induduzo, kuba umntu omdala uya kudlula eluswini nangona kungekho juluko (i-sweat ephawulekayo) yonke imihla I-capillary ikhupha umphunga wamanzi (obizwa ngokuba yi-sweat efihliweyo), i-30- 70 g/ngosuku*umntu. Emva koko ubuninzi bobu bumanzi bufuna ukuhanjiswa ngempahla. Kuphela xa ukukwazi kwempahla yokuhambisa umswakama kudlula eli xabiso abantu banokuziva bekhululekile. Ngenxa yesi sizathu, kubaluleke kakhulu ukufumanisa ukuxhathisa ukufuma.

lUxhaso lobuchwepheshe

6.1 Ukuchongwa kweempazamo

A, Akukho mboniso kwi-boot screen

- Jonga ukuba amandla avuliwe na

- Jonga ukuba amandla omboniso aqhagamshelwe

- Jonga ukuba amandla omboniso aqhagamshelwe

B, Iqondo lobushushu rhoqo kunye nokufuma akukwazi ukubaleka

- Inqanaba lamanzi kwi-interface ye-boot lityheli, nceda wongeze amanzi

- Khangela ukuba umgca wokudibanisa phakathi kwebhodi yokulawula kunye nebhodi yokuqhuba idibene kakuhle

- Khangela ukuba uxinzelelo lwecompressor yefriji luphezulu okanye luphantsi kunoxinzelelo olubekiwe

C, ubushushu rhoqo kunye nokusebenza ukufuma, iqondo lobushushu eliphantsi igumbi uvavanyo

- Khangela ukuba ityhubhu yokufudumeza umoya inokufudunyezwa ngokuqhelekileyo;

- Jonga i-slid state relay eqhuba ityhubhu yokufudumeza umoya.

D, Ubushushu kunye nokusebenza kokufuma, ukufuma okuphantsi kwigumbi lovavanyo

- Khangela ukuba umbhobho wokufudumeza wetanki yamanzi unokufudunyezwa ngokuqhelekileyo

- Jonga i-slid state relay eqhuba umbhobho wokufudumeza wetanki yamanzi

E, Akukho umboniso wobushushu kwibhodi yovavanyo, ibhodi yokufudumeza okanye ezantsi

1. Ingaba inzwa yokushisa itshisiwe

2. Uqhagamshelwano lwesiqhagamshelo alulungile, lufake kwakhona.

F, Ibhodi yovavanyo, ibhodi yokufudumeza okanye ipleyiti esezantsi ayinakufudumeza okanye ifudumeze ngokucothayo

1. Jonga ukuba ngaba izinto ezintathu zokutshintsha umbane zidla ngokubonelelwa ngamandla;

2. Khangela isiphaluka solawulo lwe-heater ukuze ubone ukuba kukho uqhagamshelwano olubi kunye neplagi engathanga ngqo.

6.2 Ugcino

A. Musa ukungqubana namacandelo ahlukeneyo ngexesha lokuthutha, ukufakwa, ukulungiswa kunye nokusetyenziswa kwesixhobo ukuphepha umonakalo womatshini kunye nokuchaphazela iziphumo zovavanyo.

B. Iphaneli yokulawula yesixhobo yikristale ye-liquid kunye nesikrini sokuchukumisa, ezonakala ngokulula. Musa ukusebenzisa ezinye izinto ezomeleleyo endaweni yeminwe yakho ngexesha lokusebenza. Musa ukuthontsiza i-solvents ye-organic kwisikrini sokuchukumisa ukunqanda ukwenza bufutshane ubomi benkonzo.

C. Yenza umsebenzi omhle wokunyanga uthuli emva kokusetyenziswa kwesixhobo ngasinye kwaye uhlambulule uthuli ngexesha.

D. Xa isixhobo singasebenzi kakuhle, nceda ucele ingcali ukulungisa okanye ukulungisa phantsi kolwalathiso lwengcali.

lIingxaki eziqhelekileyo

7.1 Umbuzo wexesha lokubona

Ixesha lokufunyanwa ngumcimbi oxhalabisa kakhulu kuye wonke umntu, kwaye ndihlala ndinethemba lokukhawuleza kwaye ichanekile. Ekubeni umgangatho wangaphambili uchaza umlinganiselo wemijikelezo emihlanu yombane kunye nexesha lokucima amandla kuyo nayiphi na isampuli emva kwemizuzu ye-30 yokufudumeza ukubala umphumo, malunga neyure ukuvavanya idatha enye. Kukho ingqikelelo enjalo yokuba ndihlala ndiziva ukuba ixesha lovavanyo lwangoku lide kakhulu. Ixesha lokufudumala kwinqanaba lendlela yangoku ligxininisa imfuneko yokufikelela kwisimo esizinzileyo, kunokuba ixesha elidlulileyo elimiselweyo. Oku kungenxa yesizathu. Ngenxa yokuba uluhlu lokumelana ne-thermal ye-textile lukhulu, kufuneka lufikelele kuma-35 ° C kwelinye icala kunye ne-20 ° C kwelinye icala. Ixesha elifunekayo lemeko ezinzileyo yahlukile. Umzekelo, kuthatha iiyure ezi-2 ubuncinane ukuba iidyasi zifikelele kwisimo esizinzileyo, ngelixa iibhatyi ezisezantsi zithatha ixesha elide. Kwelinye icala, amalaphu amaninzi afunxa ukufuma. Nangona isampuli ilungisiwe kwaye ilungelelaniswe kwangaphambili, imeko yovavanyo itshintshile. Ubushushu bendawo yangaphambili yi-20℃ kwaye ukufuma yi-65%, ngelixa i-35℃ kwelinye icala kunye ne-20℃ kwelinye. Ukufuma kwakhona kwesampulu emva kokuba ibhalansi iyatshintsha. Senze uvavanyo lokuthelekisa. Ubunzima bangaphambili besampulu efanayo bukhulu kunokuqala. Wonke umntu uyazi ukuba kuthatha ixesha elide ukulungelelanisa ukufuma kwakhona kwamalaphu. Ngoko ke, ixesha lokufumanisa ukuchasana kwe-thermal alikwazi ukuba lifutshane.

Kwakhona kuthatha ixesha elide ukuba isampuli ifikelele kwi-isothermal kunye noxinzelelo lwamanzi olungalinganiyo ngexesha lovavanyo lokumelana nokufuma.

Kuyafana nexesha elifunekayo kwizixhobo ezifanayo zangaphandle zokubona "ukuchasana kwe-thermal kunye nomswakama", nceda ubhekisele kwi-appendix.

7.2 Umbuzo wobungakanani besampulu

Ubungakanani besampuli buhlala bungcono. Akunjalo kuvavanyo lokumelana ne-thermal. Ichanekile kuphela kummeli wesampuli, kodwa isiphelo esichasayo sinokuthathwa kwisixhobo. Ubungakanani bebhodi yovavanyo inkulu kwaye ukufudumeza yi-Uniformity yingxaki. Umgangatho omtsha ufuna isantya somoya esiyi-1m/s. Ubukhulu besayizi, mkhulu umehluko wesantya phakathi kwendawo yokungena kunye ne-air outlet, kunye nokwanda kweqondo lokushisa lomoya kunye nobushushu bendawo yokuphuma . Ukususela kuphuhliso lwemigangatho yasekhaya nakwamanye amazwe, siyabona ukuba umgangatho omdala ubukhulu becala yi-250mm2 kwaye umgangatho omtsha yi-200mm2. I-KES yaseJapan isebenzisa i-100mm2. Ngoko ke, sikholelwa ukuba i-200 mm2 ifaneleke ngakumbi kwindawo esebenzayo phantsi kwesiseko sokuhlangabezana nemigangatho yendlela.

7.3 Ingaba iqondo lokushisa lokusetha lihambelana nexabiso lokumelana ne-thermal

Ngokuqhelekileyo, iqondo lokushisa lokusetha alikho malunga nexabiso lokumelana ne-thermal.

Ixabiso lokumelana ne-thermal lihambelana nommandla wesampuli, umehluko weqondo lokushisa phakathi kwamacala amabini, kunye namandla afunekayo ukuze kugcinwe imeko ezinzileyo.

Rct

Emva kokuba indawo yebhodi yokuvavanya inqunywe, ubukhulu bayo akufanele butshintshe. Ngethuba nje iqondo lokushisa kwiiphelo zombini lihlala lihlala, akunzima ukulinganisa amandla afunekayo ukuze kugcinwe rhoqo. Ingabonwa ukuba iqondo lokushisa elisetyenzisiweyo alibalulekanga, ukuba nje ukushisa okusetyenzisiweyo akutshintshi iimpawu zento elinganisiweyo. unako. Ewe siyawuhlonipha umgangatho kwaye samkela i-35℃.

7.4 Kufunyenwe ingxaki yesalathiso

Kutheni umgangatho omtsha uphelisa izinga lokugcinwa kobushushu kwaye wamkele isalathiso sokumelana ne-thermal? Sinokwazi kwifomula yokuqala yogcino lobushushu:

Q1(Akukho sampuli yokulahla ubushushu (W/℃)

Q2(ngesampulu yokulahla ubushushu (W/℃)

Ngokuphuculwa kokusebenza kwe-thermal, i-Q2 iyancipha ngokulandelelana, kodwa izinga lokufakelwa kwe-thermal Q likhuphuka ngokucothayo. Ekusetyenzisweni kwangempela, izinga lokufakelwa kwe-thermal yengubo yomgca wesibini kunye nengubo enye yokwenyuka inyuswe nje encinci, ayiphindwe kabini. Olu luyilo lwefomula Ngoko ke, kunengqiqo ukuphelisa esi salathisi kumazwe ngamazwe. Okwesibini, ukuxhathisa kwe-thermal kulula kakhulu ukuyisebenzisa, kwaye ixabiso longezwa ngokuhambelana. Ngokomzekelo, idyasi yokuqala yi-0.085 m2·K/W, yaye umgangatho wesibini yi-0.170 m2·K/W.

Ubudlelwane phakathi kokunganyangeki kwe-thermal kunye nesantya sokugquma:

Rct=A/Q2—Rct0 A: indawo yovavanyo

Ngokutsho kwefomula, ukuchasana kwe-thermal kutshintsha ngokutshintsha kwe-Q2.

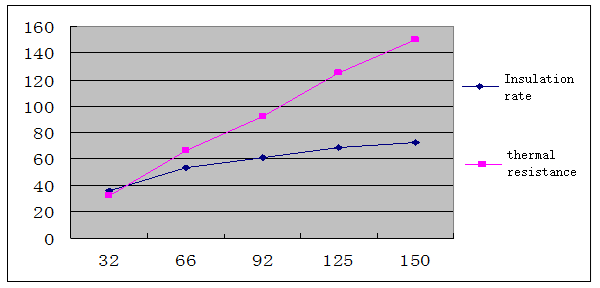

Le mizekelo ilandelayo yedatha yovavanyo lokumelana nobushushu:

| Amaxesha ovavanyo | 1 | 2 | 3 | 4 | 5 | I-thermal engenanto |

| Idatha yokumelana nobushushu (10-3m2·K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

A yi 0.04m2kwaye i-Q2 iya kuba:

| Amaxesha ovavanyo | 1 | 2 | 3 | 4 | 5 | Idatha yokumelana nokushisa |

| Idatha yokuxhathisa i-Thermal 10-3m2·K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

| Q2 (W/℃) | 0.4444 | 0.3226 | 0.2667 | 0.2186 | 0.1923 |

|

Q1 Akukho sampuli yokuchitha ubushushu, Q1=A/Rct0=0.04/58*1000=0.6897

| Amaxesha ovavanyo | 1 | 2 | 3 | 4 | 5 | Idatha yokumelana nokushisa |

| Ukumelana nobushushu (10-3m2·K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

| Q2 (W/℃) | 0.4444 | 0.3226 | 0.2667 | 0.2186 | 0.1923 |

|

| Izinga lokugquma (%) | 35.57 | 53.22 | 61.33 | 68.31 | 72.12 |

|

Ngokwedatha, umzobo wegophe wokuxhathisa i-thermal kunye nesantya sokugquma:

t kunokubonwa kule nto njengoko ukuchasana kwe-thermal kuba kukhulu, izinga lokugcinwa kokufudumala lihlala lithe tyaba, oko kukuthi, xa ukuchasana kwe-thermal kukhulu, izinga lokugcinwa kokufudumala kunzima ukubonisa ukuba lukhulu ngokwenene.

7.5 Ukulungelelaniswa kwesixhobo kunye neengxaki zesampuli eziqhelekileyo

Ukuqinisekiswa kwezixhobo zokumelana ne-thermal kunye nokufuma kuye kwaba yingxaki enkulu. Ukuba iqondo lokushisa kweplate ephantsi liza kulinganiswa, alikwazi ukufunyanwa ngenxa yokuba isixhobo sitywinwe. Zininzi kakhulu izinto ezichaphazela iziphumo zovavanyo. Iindlela zokuqinisekisa zangaphambili zinzima kwaye azizange zisombulule ingxaki. Kuyaziwa ukuba ukuguquguquka kweziphumo zovavanyo lwesixhobo sokufakelwa kwe-thermal yinyani engenakuphikiswa. Ngokophononongo lwethu lwexesha elide, sikholelwa ukuba "isampulu eqhelekileyo" isetyenziselwa ukuqinisekisa "imitha yokumelana ne-thermal" "Iyamkelekile kwaye isayensi.

Kukho iindidi ezimbini zeesampulu eziqhelekileyo. Enye kukusebenzisa amalaphu (ikhemikhali ifiber plain weave), kwaye enye sisipontshi.

Nangona i-textiles ingachazwanga kwimigangatho yasekhaya nakwamanye amazwe, i-multi-layer superposition method isetyenziswa ngokucacileyo ukulinganisa isixhobo.

Emva kophando lwethu, sikholelwa ukuba akukho ngqiqweni ukusebenzisa indlela ye-superposition, ngakumbi i-textile superimposition. Wonke umntu uyazi ukuba emva kokuba i-textile ibekwe phezulu, kukho izithuba phakathi, kwaye kusekho umoya kwi-gap. Ukumelana ne-thermal yomoya we-static kungaphezulu kokuphindwe kabini ukuxhathisa kwe-thermal nayiphi na i-textile. Ubungakanani be-gap bukhulu kunobunzima be-textile, oku kuthetha ukuba ukuchasana kwe-thermal okwenziwa yi-gap akuncinci. Ngaphandle koko, i-gap ye-overlap yahlukile kuvavanyo ngalunye, ekunzima ukuyilungisa, okubangela ukupakishwa okungahambelaniyo kweesampuli eziqhelekileyo.

Isiponji asinazo ezi ngxaki zingasentla. Iisampulu eziqhelekileyo ezinokumelana ne-thermal eyahlukeneyo zibalulekile, azikho phezulu, ezifana ne-5mm, i-10mm, i-20mm, njl njl good) Ukucacisa ukuba amaqamza kwisiponji ayafana, oku kungasentla kubhekisa kumsantsa ongezelelweyo phakathi kweemaleko.

Emva kovavanyo oluninzi, isiponji sisixhobo esiluncedo kakhulu nesisebenzayo. Kucetyiswa ukuba iyunithi ekugxilwe kuyo esemgangathweni yamkelwe.

Isihlomelo

Ixesha lereferensi yovavanyo

| Iindidi zesampuli | Ixesha lokumelana nobushushu (min) | Ixesha lokuxhathisa ukufuma (min) |

| Ilaphu elibhityileyo | Malunga ne 40~50 | Malunga ne 50~60 |

| Ilaphu eliphakathi | Malunga ne 50~60 | Malunga 60~80 |

| Ilaphu elishinyeneyo | Malunga 60~80 | Malunga 80~110 |

Qaphela: Eli xesha lovavanyo lingentla liphantse lilingane nezixhobo ezifanayo ehlabathini

SHANDONG DRICK Instruments CO.,LTD

Iprofayile yekhampani

I-Shandong Drick Instruments Co., Ltd, ibandakanyeka ikakhulu kuphando kunye nophuhliso, ukuveliswa kunye nokuthengiswa kwezixhobo zokuvavanya.

Inkampani yasekwa ngo-2004.

Iimveliso zisetyenziswa kwiiyunithi zophando lwezenzululwazi, amaziko okuhlola umgangatho, iiyunivesithi, ukupakishwa, iphepha, ushicilelo, irabha neeplastiki, iikhemikhali, ukutya, amayeza, amalaphu, kunye namanye amashishini.

UDrick unika ingqwalasela ekulimeni italente kunye nokwakhiwa kweqela, ukubambelela kumbono wophuhliso wobuchule, ukuzinikela.pragmatism, kunye nokusungula izinto ezintsha.

Ukuthobela umgaqo ojolise kubathengi, ukusombulula ezona mfuno zingxamisekileyo nezisebenzayo zabathengi, kwaye unikeze izisombululo zeklasi yokuqala kubathengi abaneemveliso ezikumgangatho ophezulu kunye nobuchwepheshe obuphambili.