IHydraulic Universal Testing Machine WAW-600D Microcomputer Elawulwa

Inkcazelo emfutshane:

I-WAW-600D iMicrocomputer eLawulwayo ye-Hydraulic Universal Testing Machine Overview: Umzimba oyintloko we-WAW-600D microcomputer elawulwa yi-electro-hydraulic servo hydraulic umatshini wokuvavanya universal wamkela isilinda ezantsi uhlobo lwesakhiwo esingundoqo somzimba, esisetyenziselwa iimvavanyo zokusebenza koomatshini ezifana noxinzelelo, uxinzelelo. , ukugoba izinto zetsimbi, izinto ezingezizo ezentsimbi, iinxalenye zemveliso, amacandelo, amacandelo olwakhiwo, kunye nomgangatho iinxalenye. Ukuba ixhotyiswe ngezixhobo zokusingqongileyo, olu thotho...

WAW-600D Microcomputer ElawulwaUmatshini woVavanyo lwe-Hydraulic Universal

Isishwankathelo seMveliso:

Umzimba ophambili we-WAW-600D microcomputer elawulwa yi-electro-hydraulic servo hydraulic umatshini wokuvavanya universal ithatha isilinda phantsi uhlobo lwesakhiwo somzimba esingundoqo, esisetyenziselwa iimvavanyo zokusebenza koomatshini ezifana noxinzelelo, ukunyanzeliswa, ukugoba izinto zetsimbi, izinto ezingezizo ezentsimbi, imveliso. amalungu, amacandelo, amacandelo esakhiwo, kunye namalungu asemgangathweni.

Ukuba ixhotyiswe ngezixhobo zokusingqongileyo, olu ngcelele loomatshini bokuvavanya lunokwenza i-tensile, uxinzelelo, kunye novavanyo lokugoba kuloo ndawo. Umzekelo: ukuqina kobushushu obuphezulu, ukunyanzeliswa kobushushu obuphantsi, uxinzelelo kunye nolunye uvavanyo.

Ifanele intsimbi, isinyithi, izixhobo zokwakha, amaziko okuhlola umgangatho, ukugcinwa kwamanzi kunye nombane wamanzi, iibhulorho zendlela, amaziko ophando, ubunjineli boomatshini kwiikholeji kunye neeyunivesithi, kunye nezinye iifektri, imigodi, amashishini, kunye novavanyo kunye namaziko ophando.

Imigangatho yokuvelisa kunye nokuhlolwa kweemveliso

GB2611 "IiMfuno zobuGcisa ngokuBanzi kuMatshini woVavanyo"

JJG139 “Ukuqina, Uxinzelelo, kunyeUmatshini woVavanyo lweHlabathi“

Imigangatho yovavanyo olusebenzayo

Ukusebenza kovavanyo kunye nokusetyenzwa kwedatha kuhlangabezana neemfuno zamakhulu emigangatho efana ne-GB/T228 “iNdlela yoVavanyo lweTensile yezinto zeMetallic kwiTemperature yeGumbi”, i-GB/T7314 “iNdlela yoVavanyo loKunyanzeliswa kweeMathiriyeli zeMetallic kuBubushushu beGumbi”, i-GB/T232 “Ukugoba Indlela yoVavanyo lweMathiriyeli yeMetallic”, njl. Kwaye iindlela zokusetyenzwa kwedatha ezihlangabezana nemigangatho eyahlukeneyo zinokuqwalaselwa ngokwe iimfuno zabathengi.

Iimpawu eziphambili zobugcisa

1 Umamkeli

I-injini engundoqo ithatha uhlobo lwe-cylinder ye-oyile ephantsi, kunye nesithuba solula esibekwe ngaphezu kwe-injini ephambili, kunye nesithuba sovavanyo lokuxinzelela kunye nokugoba phakathi kwe-crossbeam esezantsi ye-injini engundoqo kunye ne-worktable.

2 Inkqubo yoThutho

Ukuphakanyiswa kwe-crossbeam ephakathi kuthatha i-motor eqhutywa livili letsheyini ukujikeleza isikrufu, ukulungelelanisa indawo yendawo ye-crossbeam ephakathi kunye nokuphumeza ukulungelelaniswa koxinzelelo kunye nendawo yoxinzelelo.

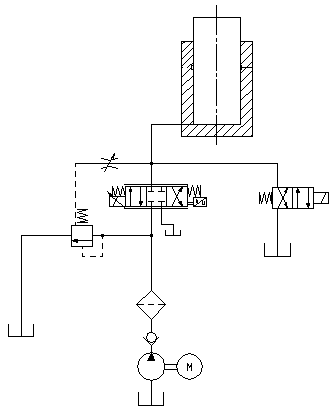

Umgaqo we-hydraulic we-hydraulic system uboniswe kuMzobo we-2, oyisistim yokulawula isantya se-oyile eguqukayo.

Umzobo we-2 Umzobo we-Hydraulic schematic

Ioyile ye-hydraulic kwitanki yeoli iqhutywa yimoto ukuba ingene kwisekethe yeoli, kwaye ihamba nge-valve yendlela enye, i-high-pressure oil filter, i-valve ye-valve eyahlukileyo, i-servo valve, kwaye ingena kwi-cylinder yeoli. Ikhompyuter ithumela imiqondiso yolawulo kwivalve ye-servo elinganayo ukulawula ukuvulwa kunye nesalathiso se-valve ye-servo elinganayo, ngaloo ndlela ilawula ukuhamba kwi-oyile cylinder kunye nokufezekisa ulawulo lwamandla ovavanyo olukhawulezayo, ukufuduswa kwesantya rhoqo, njl.

4. Umlinganiselo wombane kunye nenkqubo yokulawula:

(1) Amacandelo angundoqo omthombo we-oyile yokulawula i-servo zonke zisuka kumazwe angaphandle kunye nokusebenza okuzinzileyo.

(2) Inemisebenzi yokukhusela enjengomthwalo ogqithisiweyo, i-overcurrent, i-overvoltage, ukufuduka kwimida ephezulu nangaphantsi, kunye nokumisa ngokukhawuleza.

(3) Isilawuli esakhelwe ngaphakathi esekwe kwitekhnoloji ye-PCI siqinisekisa ukuba umatshini wokuvavanya unokufikelela kulawulo oluvaliweyo lweeparamitha ezinje ngovavanyo lwamandla, i-specimen deformation, kunye nokufuduswa komqadi, kwaye unokwenza iimvavanyo ezinje ngokunyanzeliswa kovavanyo lwesantya, isantya esingagungqiyo. ukufuduswa, ukuqina kwesantya esingaguqukiyo, umjikelo wesantya esingaguqukiyo womthwalo, kunye nomjikelo wokuguquguquka kwesantya esingaguqukiyo. Ukutshintsha okugudileyo phakathi kweendlela ezahlukeneyo zolawulo kunokwenzeka.

(4) Ekupheleni kovavanyo, inokubuyiselwa ngesandla okanye ngokuzenzekelayo kwindawo yokuqala yovavanyo ngesantya esiphezulu.

(5) Ifezekise i-zeroing yangempela yomzimba, ukufumana ulungelelwaniso, kunye nokutshintsha ngokuzenzekelayo, ukulinganisa, ukulinganisa, kunye nokugcinwa kokulinganisa amandla okulinga, ngaphandle kwekhonkco lohlengahlengiso lwe-analog, kwaye isiphaluka solawulo sihlanganiswe kakhulu.

(6) Isiphaluka solawulo lombane silandela imigangatho yamazwe ngamazwe kwaye sithobela imigangatho yombane yomatshini wokuvavanya wesizwe. Inamandla okuchasana nokuphazamiseka, ukuqinisekisa ukuzinza komlawuli kunye nokuchaneka kwedatha yovavanyo.

(7) Ixhotywe nge-interface yothumelo lwenethiwekhi, inokwenza ukuhanjiswa kwedatha, ukugcinwa, iirekhodi zokuprinta, kunye nokushicilela ukuhanjiswa kwenethiwekhi, kwaye inokudityaniswa ne-LAN yangaphakathi okanye inethiwekhi ye-Intanethi yeshishini.

5. Inkcazo yeempawu eziphambili zokusebenza zesofthiwe

Le software yokulinganisa kunye nokulawula isetyenziselwa i-microcomputer elawulwa yi-electro-hydraulic servo hydraulic umatshini wokuvavanya uwonke wonke ukwenza iimvavanyo ezahlukeneyo zetsimbi kunye nezingezizo ezentsimbi, ukulinganisa ixesha lokwenyani kunye nomboniso, ulawulo lwexesha lokwenyani kunye nokusetyenzwa kwedatha, iziphumo zeziphumo kunye neminye imisebenzi ngokutsho. kwimigangatho ehambelanayo.

(1) Ulawulo olusekelwe kwimvume, apho abaqhubi kumanqanaba ahlukeneyo baneemvume zokusebenza ezahlukeneyo kunye nokufikelela kwiimenyu kunye nezinye iziqulatho. Oku akupheleli nje ngokulula, ukuququzelela, kunye nesantya sokusebenza kubasebenzi abaqhelekileyo, kodwa ikwakhusela ngokusebenzayo inkqubo;

(2) Umlinganiselo wexesha langempela kunye nokubonakaliswa kwamandla okuvavanya, ixabiso eliphezulu, ukufuduka, ukuguqulwa kunye nezinye iimpawu; Ukuqokelelwa kwexesha lokwenyani kunye nolawulo luphunyeziwe eqongeni; Kwaye kuphunyezwe ixesha elichanekileyo kunye nesampulu enesantya esiphezulu;

(3) Umboniso wesikrini sexesha langempela leejika ezahlukeneyo zokuvavanya ezifana nokuguqulwa komthwalo kunye nokufuduswa komthwalo kuphunyeziwe, okunokutshintshwa kwaye kubonwe nangaliphi na ixesha. Ukusondeza kunye nokuphuma kweegophe kulula kakhulu;

(4) Ikhompyutha inemisebenzi efana nokugcina, ukuseta, kunye nokulayisha iiparamitha zokulinga. I-Zeroing, ukulinganisa, kunye neminye imisebenzi iqhutyelwa ngesofthiwe, kwaye ipharamitha nganye inokugcinwa ngokulula kwaye ingeniswe ngaphandle, okwenza kube lula ukutshintshela phakathi kwee-sensor ezininzi kwi-host ngaphandle komda kwinani leenzwa;

(5) Ukuxhasa iindlela ezininzi zokulawula, kubandakanywa ukufuduka kwe-loop evulekileyo rhoqo, ukunyanzeliswa kwesantya esiqhubekayo, uxinzelelo lwesantya esiqhubekayo, kunye nezinye iindlela zokulawula i-loop evaliweyo; Kwaye unikeze iijika zereferensi ezisemgangathweni ngexesha lenkqubo yokulungiswa kweeparamitha ezivaliweyo ngabaqhubi abaphambili, ukwenzela ukuba abasebenzisi banokubona impembelelo yeparameter nganye kwisiphumo esivaliweyo.

(6) Ixhotyiswe ngenkqubo yengcaphephe ekrelekrele yokuseta iindlela zokulawula inkqubo yovavanyo, ukubonelela abasebenzisi abaziingcali ngeenkqubo ezizenzekelayo zokucwangcisa. Abasebenzisi banokudibanisa ngokuguquguqukayo iindlela zokulawula ezininzi kunye nesantya sokulawula ngokweemfuno zokwenyani kunye nemithetho, kwaye baphuhlise iinkqubo zolawulo ezihambelana neemfuno zabo. Isoftware yokulinganisa kunye nokulawula iya kulawula ngokuzenzekelayo inkqubo yovavanyo ngokwezicwangciso zomsebenzisi.

(7) Hlalutya idatha ngokusebenzisa ikhompyutha yomntu. Indlela yokucubungula ihlangabezana neemfuno zemigangatho esetyenziswa ngokubanzi kwaye inokuzibala ngokuzenzekelayo iiparamitha ezahlukeneyo zokusebenza njengemodyuli elastiki, amandla esivuno, kunye namandla achaziweyo angalinganiyo. Inokuthi ingenelele ngesandla kwinkqubo yokuhlalutya ukuphucula ukuchaneka kohlalutyo; Okunye ukusetyenzwa kwedatha kunokwenziwa ngokwemigangatho enikwe ngumsebenzisi.

(8) Idatha yovavanyo igcinwa kwiifayile ezibhaliweyo zemibuzo eluncedo yomsebenzisi, kwaye inokuqhutyelwa phambili ngokusebenzisa nayiphi na ingxelo yorhwebo ngokubanzi okanye isofthiwe yokucwangcisa amagama, ngelixa iququzelela ukuhanjiswa kwedatha nge-intanethi;

(9) I-curve yedatha yenkqubo yokulinga ingabhalwa kwaye igcinwe, kwaye i-curve inokugqithwa kwaye ifaniswe nohlalutyo olulula lokuthelekisa;

(10) Ingxelo yovavanyo inokuprintwa kwifomathi efunwa ngumsebenzisi. Abasebenzisi banokukhetha umxholo wengxelo yemveliso yolwazi olusisiseko, iziphumo zovavanyo, kunye neegophe zokulinga ukuhlangabezana neemfuno ezahlukeneyo;

(11) I-digital zeroing kunye nokulinganisa okuzenzekelayo kwamandla okulinga kunye nokuguqulwa kuye kwaphunyezwa, okwenza kube lula ukusebenza kunye nokuphucula ukuthembeka komatshini. Izicwangciso ezahlukeneyo zenkqubo yeparameter zigcinwa kwifom yefayile ukuze zigcinwe lula kunye nokubuyisela;

(12) Inokusetyenziswa kwinkqubo yokusebenza yeWin7. Ukulawulwa kwenkqubo yovavanyo, utshintsho kwisantya sokuhamba kwe-crossbeam, igalelo leparameter, kunye neminye imisebenzi inokugqitywa yonke ikhibhodi okanye imouse, iyenze ibe lula kwaye ikhawuleze ukuyisebenzisa;

(13) Ixhotywe ngokhuseleko lomthwalo ogqithisiweyo kunye nomsebenzi wokuvala ngokuzenzekelayo, inokubona ngokuzenzekelayo ukuphuka kwesampulu kwaye ivale ngokuzenzekelayo.

Ngokweemfuno ezahlukeneyo zomsebenzisi, le misebenzi yesoftware ingentla inokulungiswa okanye iguqulwe.

6. Ujongano lwesoftware kunye nesoftware:

(1) Isoftware inokusebenza kwi-Windows 7 inkqubo, kwaye ujongano lomsebenzisi lubonisa inkqubo yefestile yamaTshayina ehambelana nesimbo seWindows. Yonke imisebenzi yovavanyo inokugqitywa ngokufaka imouse kwiscreen sekhompyuter.

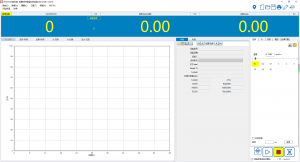

Ujongano oluphambili lomatshini wovavanyo

(Ujongano lwesoftware lwahluke kancinane, ikakhulu lusekwe kwinyani)

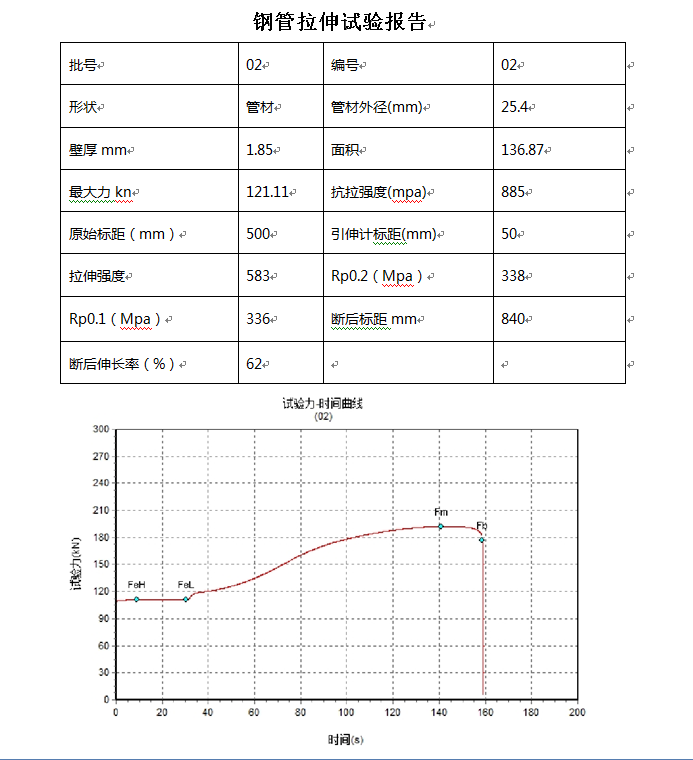

7. Ingxelo yovavanyo:

Khangela kwaye ulawule idatha yovavanyo ngokusebenzisa iifayile zedatha zovavanyo; Yenza umxholo kunye nefomathi yeengxelo zovavanyo ngokusebenzisa iisetingi zethemplate yengxelo; Ngokuhlela iifomula kunye nezinto zeziphumo, inkxaso yobuninzi bemigangatho yovavanyo kunye neendlela inokufezekiswa; Emva kokulayisha iifayile zedatha yovavanyo enye okanye ngaphezulu, velisa ingxelo yovavanyo ngokwethemplate yengxelo kwaye uyiprinte; Ixhasa iitemplates zengxelo zeLizwi kunye neExcel, kwaye inokuhlelwa ngokukhululekileyo;

(Idatha yeyereferensi kuphela kwaye ayinakubaluleka okubonakalayo)

8. Isixhobo sokukhusela ukhuseleko

(1) Xa amandla okuvavanya adlula i-2% -5% yowona mandla okuvavanya kakhulu, ukhuseleko lomthwalo ogqithisiweyo luyasebenza kwaye inkqubo iyathululwa.

(2) Xa i-piston iphakama kwindawo ephezulu, ukhuseleko lwe-stroke luyayeka kwaye i-oil pump motor iyayeka.

Ukusebenza okuphambili kunye nezalathi zobugcisa

| HAYI. | Igama leProjekthi | Iiparamitha |

| 1 | Awona mandla ovavanyo aphezulu kN | amakhulu amathandathu |

| 2 | Isakhiwo somamkeli | Iintsika ezine kunye nezikrufu ezimbini zokukhokela |

| 3 | Impazamo ezalanayo yesalathiso samandla ovavanyo | ≤ ± 1% yexabiso elibonisiweyo |

| 4 | Uluhlu lokulinganisa amandla ovavanyo | I-2% ~ 100% yamandla ovavanyo aphezulu |

| 5 | Uluhlu lolawulo loxinzelelo lwesantya rhoqo (N/mm2 · S-1) | 2-60 |

| 6 | Uluhlu lolawulo loxinzelelo rhoqo | 0.00025/s~0.0025/s |

| 7 | Uluhlu lolawulo lokufuduswa rhoqo kwesantya (mm/min) | 0.5~50 |

| 8 | inkqubo yokubamba | I-hydraulic clamping |

| 9 | Isampulu yesampulu yesampulu ebambekayo yoluhlu lwedayamitha mm | Khetha nayiphi na iseti phakathi koluhlu lwe Φ 6 ukuya ku Φ 40 |

| 10 | Umzekelo osicaba wokubamba ubukhulu boluhlu mm | 0~15 |

| 11 | Umzekelo osicaba wokubamba ububanzi mm | Amashumi asixhenxe |

| 12 | Esona sithuba siphezulu sovavanyo mm | 550 (ubungakanani bunokwenziwa ngokwezifiso) |

| 13 | Ubuninzi besithuba sovavanyo loxinzelelo mm | 500 (ubungakanani bunokwenziwa ngokwezifiso) |

| 14 | Imilinganiselo yekhabhinethi yokulawula yangaphandle mm | 1100×620×850 |

| 15 | Imilinganiselo yokusingatha kwiimilimitha | 900 × 630 × 2300 (ubungakanani bungenziwa ngokwezifiso) |

| 16 | Amandla emoto kW | amanqaku amabini amathathu |

| 17 | Ubunzima bomamkeli kg | iwaka elinamakhulu amahlanu |

| 18 | Umgama osembindini weKholam (mm) | amakhulu amane anamanci mahlanu |

| 19 | Ubungakanani bepleyiti yoxinzelelo oluphezulu nasezantsi mm | Φ160 |

| 20 | Isithuba sentonga egobayo mm | 450 (ubungakanani bunokwenziwa ngokwezifiso) |

| 21 | Ububanzi bentonga yokuxhasa ukugoba mm | 140 (ubungakanani bunokwenziwa ngokwezifiso) |

| 22 | Iqondo lokugoba elivumelekileyo mm | 100 (ubungakanani bunokwenziwa ngokwezifiso) |

| 23 | Ubuphezulu piston stroke mm | amawaka amabini |

| 24 | Ubuninzi besantya sokuhamba kwepiston mm/min | Malunga nama-60 |

| 25 | Isantya sohlengahlengiso lwendawo yovavanyo mm/min | Malunga ne-150 |

Ubumbeko olusemgangathweni

| HAYI. | Igama | Iinkcukacha | Qty. | izimvo |

| 1 | umamkeli |

| Iseti e-1 | Uzenzele |

| 2 | Umthombo weoyile olawulwa nguServo |

| Iseti e-1 | Uzenzele |

| 4 | Ikhabhinethi yokulawula |

| Iseti e-1 | Uzenzele |

| 5 | Umlinganiselo kunye neNkqubo yoLawulo |

| Iseti e-1 | Uzenzele |

| 6 | Isivamvo sokuthetha ivili |

| 1pcs | Uvavanyo olubanzi |

| 7 | Ukolula ikhowudi |

| 1pcs | UJinan |

| 8 | ikhompyutha |

| Iseti e-1 | HP |

| 9 | umshicileli |

| Iseti e-1 | HP |

| 10 | Isampulu yemihlathi engqukuva mm | Khetha nasiphi na iperi kuluhlu lwe Φ 6- Φ 13, Φ 13- Φ 26, kunye Φ 26- Φ 40 | 1pcs | Uzenzele

|

| 11 | Isampulu yemihlathi ecaba mm | 0~15 | 1pcs | |

| 12 | Uxinzelelo oluncamathiselwe mm | Φ150 | Iseti e-1 | Uzenzele |

| 13 | Impompo yeoli |

| Iseti e-1 | Mazzic, eItali |

| 14 | oomatshini bombane |

| Iseti e-1 | Shanghai Songhui |

| 15 | Amaxwebhu obugcisa | Incwadi yomsebenzisi, uluhlu lokupakisha, isatifikethi sokuthotyelwa | 1pcs | Uzenzele |

Iinkqubo zokusebenza:

Iinkqubo zokusebenza kumatshini wokuvavanya i-electro-hydraulic servo

1. Qala ikhompyuter kwaye ufake isoftware

2. Qalisa ukutshintshwa kwamandla kunye nomthombo weoli oyintloko yokutshintsha kwe-electro-hydraulic servo controller

3. Lungisa i-crossbeam yeziko lomqhubi womatshini wokuvavanya kwindawo efanelekileyo, kwaye ubuyisele indawo efanelekileyo ngokumalunga nemilo, ubungakanani kunye nenjongo yovavanyo yesampuli.

4. Vula ukutshintshwa kwamandla epompo yeoli kwaye uphakamise i-cylinder yeoli yomatshini wokuvavanya ukuphelisa ubunzima bayo. (Unokukhetha isantya sokufuduka se-10mm/min kwaye nqakraza iqhosha elithi [Phezulu] ukunyusa i-cylinder yeoli malunga ne-1mm).

5. Faka ulwazi olufanelekileyo malunga nesitayela kwinguqu yedatha yesofthiwe.

6. Emva kokucinezela isitayile kumhlathi ongasentla, phinda umisele ixabiso lamandla libe ngu-zero, lungisa i-crossbeam ephakathi kwindawo efanelekileyo, qinisa umhlathi ongezantsi, kwaye usete ngokutsha ukufuduswa kunye nokuguqulwa. (Isitayile kufuneka sibotshwe ngaphezulu kwe-80% yemihlathi yonke, kwaye sigcinwe sithe nkqo kwaye silungelelanisiwe)

7. Khetha isantya esifanelekileyo okanye isicwangciso, cofa i 【Qala】 iqhosha kwisoftware, kwaye wenze uvavanyo.

Emva kokuqhekeka kwesampulu, uvavanyo luphela ngokuzenzekelayo. Ukujonga idatha yovavanyo, cofa kuguqulelo lwedatha kwisoftware ukujonga idatha efunekayo

Emva kokugqitywa kwazo zonke iimvavanyo zesampulu, i-oyile cylinder piston iwela ezantsi kwi-oyile cylinder kwaye iswitshi ephambili yeoyile iyacinywa.

8. Phuma kwisoftware yokusebenza, vala ikhompyuter, kwaye ucime amandla omkhosi.

Ingqalelo:

1. Iintsimbi zentsimbi emihlathini yomatshini wokuvavanya kufuneka zisuswe rhoqo ukuze kugcinwe imihlathi ecocekileyo

Xa ukucoca izixhobo kunye nokugcina ucoceko kwindawo yokusebenza, amandla kufuneka anqanyulwe

Ngexesha lovavanyo, ukuba impompo yeoyile iyeka ukusebenza ngequbuliso, umthwalo osetyenzisiweyo kufuneka uthulwe, uhlolwe, kwaye impompo yeoli kufuneka iqalwe kwakhona.

Xa umatshini wokuvavanya umisiwe okwesikhashana, i-oil pump motor kufuneka icinywe, kwaye ibhentshi yokuvavanya kufuneka ithotywe emva kokuba uvavanyo lugqityiwe. Ipiston yesilinda yeoli akufuneki iwele ezantsi kwe-cylinder kwaye iphume kumgama othile ukuququzelela ukusetyenziswa kwexesha elizayo.

5. Kuphephe ukuvumela isixhobo sifume okanye sidibane nezinto ezingamanzi, kwaye uthintele isixhobo ukuba singashukunyiswa okanye sichaphazeleke.

6. Nceda ungalishiyi igumbi lotyando kwaye ucinezele iswitshi yokumisa kaxakeka kwimeko kaxakeka

7. Hlala kude nokuphazamiseka kwamagnetic

8. Abasebenzi bezobugcisa abangezongcali abavumelekanga ukuba baguqule iprogram yesoftware yomatshini wovavanyo

Ukuqinisekisa umgangatho

Inkampani iqinisekisa ukuba zonke iimveliso ziveliswa ngokuhambelana nemigangatho yesizwe ehambelanayo;

Inkampani iqinisekisa ukuba zonke izixhobo zasekhaya zivela kwiimpawu ezaziwayo ezinomgangatho obalaseleyo;

Inkampani iqinisekisa ukuba zonke izixhobo zangaphandle ziyimveliso yoqobo kunye neyenyani evela kumzi-mveliso;

Inkampani iqinisekisa ukuba iimveliso ezinikezelwe kubasebenzisi ngoomatshini abatsha bokuqala;

Inkampani iqinisekisa ukuba zonke iimveliso ezishiya umzi-mveliso zihlolwa ngokungqongqo ngokwemigaqo;

Inkampani ithembisa ukwamkela abathengi ukuba batyelele kwaye babeke iliso kulo mzi-mveliso nangaliphi na ixesha.

Iimeko zolungiselelo lomsebenzisi

Abasebenzi abanezakhono kwizicelo zekhompyuter;

Umsebenzisi kufuneka acacise iindlela zovavanyo kunye neenkcukacha ezisemgangathweni apho uvavanyo lubhekisa kwaye lulandele;

Ukubonelela ngeesampulu eziye zavavanywa kulo matshini wokuvavanya imveliso, ukuhlolwa kwefektri, kunye novavanyo lokulungelelanisa umatshini;

Indawo, isiseko, unikezelo lwamandla, njl.njl efunekayo kufakelo lwemveliso;

Ilabhoratri kufuneka ixhotyiswe nge-air conditioning, kunye nobushushu bangaphakathi obulawulwa phakathi kwe-15-25 ℃ kunye nokufuma <70%;

Unoxanduva lokufumana, ukugcina, kunye nokuhambisa iimveliso;

Ukusetyenziswa kunye nokugcinwa

Abasebenzi bovavanyo olusisigxina kunye nabaqeqeshiweyo kufuneka balungiselelwe ukusebenzisa imveliso, kwaye abanye abavumelekanga ukuba bayisebenzise;

Xa usebenzisa imveliso, abaqhubi kufuneka balandele uqeqesho kunye nesikhokelo abasifumeneyo sokuyisebenzisa ngendlela eyiyo;

Abaqhubi kufuneka babe nobuchule kwimigangatho yovavanyo ehambelanayo ukuze baqinisekise ngokuchanekileyo iziphumo zovavanyo;

Abaqhubi kufuneka bafunde ngononophelo incwadi yokusingatha kunye nesoftware yesoftware;

Ekupheleni kovavanyo, cima umatshini ngendlela efanelekileyo kwaye unqumle yonke imithombo yamandla;

Ukuba izixhobo ezincedisayo zokuvavanya ezenziwe ngokwakho zisetyenzisiwe, isakhiwo sokuqala semveliso akufanele sitshintshwe okanye sonakaliswe ngexesha lofakelo;

Ukuba kukho imeko engaqhelekanga okanye ukusilela kombane ngexesha lokusebenza komatshini wokuvavanya, kwaye iqhosha lokuqala okanye lokuyeka alisebenzi, amandla kufuneka anqunyulwe ngokukhawuleza ukumisa umatshini wokuvavanya ukusebenza;

I-screw kunye neendawo zokuhambisa kufuneka zifakwe rhoqo ngeoli yokuthambisa ukuthintela ukukhuhlana okomileyo;

Ukuba imveliso ingasebenzi kakuhle, nceda uqhagamshelane nesebe lethu lenkonzo yabathengi ngexesha elifanelekileyo kwaye ungalihluli ngokuthe ngqo ngaphandle kokugunyaziswa;

Musa ukuyiguqula imveliso ngokwakho.

SHANDONG DRICK Instruments CO.,LTD

Iprofayile yekhampani

I-Shandong Drick Instruments Co., Ltd, ibandakanyeka ikakhulu kuphando kunye nophuhliso, ukuveliswa kunye nokuthengiswa kwezixhobo zokuvavanya.

Inkampani yasekwa ngo-2004.

Iimveliso zisetyenziswa kwiiyunithi zophando lwezenzululwazi, amaziko okuhlola umgangatho, iiyunivesithi, ukupakishwa, iphepha, ushicilelo, irabha kunye neeplastiki, iikhemikhali, ukutya, amayeza, amalaphu, kunye namanye amashishini.

UDrick unika ingqwalasela ekulimeni italente kunye nokwakhiwa kweqela, ukubambelela kumbono wophuhliso wobuchule, ukuzinikela.pragmatism, kunye nokusungula izinto ezintsha.

Ukuthobela umgaqo ojolise kubathengi, ukusombulula ezona mfuno zingxamisekileyo nezisebenzayo zabathengi, kwaye unikeze izisombululo zeklasi yokuqala kubathengi abaneemveliso ezikumgangatho ophezulu kunye nobuchwepheshe obuphambili.