Umshini Wokuhlola I-Hydraulic Universal Testing WAW-600D Microcomputer Elawulwa

Incazelo emfushane:

I-WAW-600D I-Microcomputer Elawulwa I-Hydraulic Universal Testing Machine Uhlolojikelele Lomkhiqizo: Indikimba eyinhloko ye-WAW-600D microcomputer elawulwa yi-electro-hydraulic servo hydraulic universal testing umshini isebenzisa isilinda phansi sohlobo oluyinhloko lwesakhiwo, esisetshenziselwa izivivinyo zokusebenza kwemishini ezifana nokushuba, ukucindezela. , ukugoba kwezinto zensimbi, izinto ezingezona ezensimbi, izingxenye zomkhiqizo, izingxenye, izakhi zesakhiwo, kanye nezinga izingxenye. Uma ifakwe amadivayisi emvelo, lolu chungechunge...

I-WAW-600D I-Microcomputer ElawulwaUmshini Wokuhlola I-Hydraulic Universal

Ukubuka konke komkhiqizo:

Umzimba oyinhloko we-WAW-600D microcomputer elawulwa yi-electro-hydraulic servo hydraulic universal testing umshini wamukela isakhiwo somzimba esiyinhloko se-cylinder down, ikakhulukazi esetshenziselwa ukuhlola ukusebenza kwemishini njengokushuba, ukucindezelwa, ukugoba kwezinto zensimbi, izinto ezingezona ezensimbi, umkhiqizo. izingxenye, izingxenye, izingxenye zesakhiwo, nezingxenye ezijwayelekile.

Uma ifakwe imishini yezemvelo, lolu chungechunge lwemishini yokuhlola lungakwazi nokwenza izivivinyo eziqinile, zokucindezelwa, kanye nokugoba kuleyo ndawo. Isibonelo: ukushisa okuphezulu kwezinga lokushisa, ukushisa okuphansi kwezinga lokushisa, ukucindezela nokunye ukuhlola.

Ifanele insimbi, insimbi, izinto zokwakha, izikhungo zokuhlola izinga, ukongiwa kwamanzi namandla aphehlwa ngamanzi, amabhuloho emigwaqo emikhulu, izikhungo zocwaningo, ubunjiniyela bemishini emakolishi nasemanyuvesi, nezinye izimboni, izimayini, amabhizinisi, nezikhungo zokuhlola nezocwaningo.

Amazinga okukhiqiza nokuhlola imikhiqizo

I-GB2611 "Izimfuneko Zobuchwepheshe Ezijwayelekile Zemishini Yokuhlola"

JJG139 “Ukuqina, Ukucindezela, kanyeUmshini Wokuhlola Wendawo Yonke“

Amazinga endlela yokuhlola asebenzayo

Ukusebenza kokuhlola nokucubungula idatha kuhlangabezana nezimfuneko zamakhulu ezindinganiso ezifana ne-GB/T228 “Indlela Yokuhlola I-Tensile Yezinto Zensimbi Egumbini Lezinga lokushisa”, i-GB/T7314 “Indlela Yokuhlola Ukucindezela Kwezinto Zensimbi Emazingeni Okushisa Egumbi”, GB/T232 “Ukugoba Indlela Yokuhlola Yezinto Zensimbi”, njll. Futhi izindlela zokucubungula idatha ezihlangabezana namazinga ahlukene zingahlelwa ngokuya izidingo zekhasimende.

Izinkomba zobuchwepheshe eziyinhloko

1 Umsingathi

Injini eyinhloko ithatha uhlobo lwesilinda sikawoyela obekwe ngezansi, nesikhala esinwebekayo esitholakala ngenhla kwenjini eyinhloko, kanye nesikhala sokuhlola sokuminyanisa nokugoba esitholakala phakathi kwe-crossbeam engezansi yenjini eyinhloko netafula lokusebenza.

2 Uhlelo lokudlulisa

Ukuphakanyiswa kwe-crossbeam emaphakathi kusebenzisa i-motor eshayelwa isondo leketanga ukuze kuzungeziswe isikulufu, ilungise indawo ye-crossbeam emaphakathi futhi ifinyelele ukulungiswa kwesikhala esishubile nesicindezelayo.

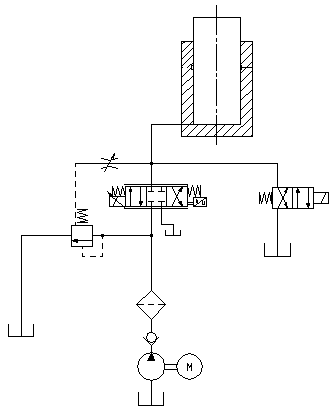

Umgomo we-hydraulic wesistimu ye-hydraulic ukhonjiswe kuMfanekiso 2, okuwuhlelo lokulawula ijubane lokungenisa i-oyili oluguquguqukayo.

Umfanekiso 2 Umdwebo we-Hydraulic schematic

Uwoyela we-hydraulic ethangini likawoyela ushayelwa injini ukuze ungene kumjikelezo kawoyela, futhi ugeleza nge-valve yendlela eyodwa, isihlungi samafutha okucindezela okuphezulu, iqembu le-valve yokucindezela okuhlukile, i-servo valve, futhi ingena kusilinda samafutha. Ikhompiyutha ithumela amasiginali okulawula ku-valve ye-servo elinganayo ukuze ilawule ukuvuleka nokuqondisa kwe-valve ye-servo elinganayo, ngaleyo ndlela ilawule ukugeleza ku-cylinder kawoyela futhi ifinyelele ukulawula kwamandla okuhlola isivinini esingaguquki, ukugudluzwa kwesivinini njalo, njll.

4. Isistimu yokulinganisa nokulawula kagesi:

(1) Izingxenye eziyinhloko zomthombo kawoyela olawula i-servo zonke ziyizingxenye zangempela ezingenisiwe ezisebenza ngokuzinzile.

(2) Inemisebenzi yokuvikela enjengokulayisha ngokweqile, i-overcurrent, i-overvoltage, ukugudluzwa kwemikhawulo ephezulu naphansi, kanye nesitobhi esiphuthumayo.

(3) Isilawuli esakhelwe ngaphakathi esisekelwe kubuchwepheshe be-PCI siqinisekisa ukuthi umshini wokuhlola ungafinyelela ukulawulwa kwe-loop evaliwe yamapharamitha njengamandla okuhlola, ukuguqulwa kwesifanekiso, nokususwa kwe-beam, futhi singenza izivivinyo ezifana namandla okuhlola isivinini esingaguquki, isivinini esingaguquki. ukugudluka, ukuqina kwesivinini okungaguquki, umjikelezo wokulayisha wesivinini ongaguquki, kanye nomjikelezo wokuguquguquka kwesivinini. Ukushintsha okubushelelezi phakathi kwezindlela zokulawula ezihlukahlukene kungenzeka.

(4) Ekupheleni kokuhlolwa, kungabuyiselwa ngesandla noma ngokuzenzakalelayo endaweni yokuqala yokuhlolwa ngesivinini esikhulu.

(5) Ithole i-zeroing yangempela yomzimba, ukulungiswa kwenzuzo, kanye nokuguquguquka okuzenzakalelayo, ukumisa, ukulinganisa, nokugcinwa kokulinganisa amandla okuhlola, ngaphandle kwanoma yiziphi izixhumanisi zokulungisa i-analog, futhi isifunda sokulawula sihlanganiswe kakhulu.

(6) Isifunda sokulawula ugesi silandela izindinganiso zamazwe ngamazwe futhi sithobelana nezindinganiso zikagesi zomshini wokuhlola kazwelonke. Inekhono eliqinile lokulwa nokuphazamiseka, iqinisekisa ukuzinza kwesilawuli kanye nokunemba kwedatha yokuhlola.

(7) Ifakwe isixhumi esibonakalayo sokudlulisa inethiwekhi, ingenza ukudluliswa kwedatha, ukugcinwa, amarekhodi okuphrinta, nokuphrinta kokudluliselwa kwenethiwekhi, futhi ingaxhunywa ku-LAN yangaphakathi noma inethiwekhi ye-inthanethi yebhizinisi.

5. Incazelo yezici zokusebenza eziyinhloko zesofthiwe

Le software yokulinganisa nokulawula isetshenziselwa umshini wokuhlola umhlaba wonke olawulwa yi-microcomputer olawulwa yi-electro-hydraulic servo hydraulic ukuze wenze izivivinyo ezihlukahlukene zensimbi nezingezona ezensimbi, ukulinganisa okuphelele kwesikhathi sangempela nokuboniswa, ukulawula kwesikhathi sangempela nokucubungula idatha, ukuphuma kwemiphumela neminye imisebenzi ngokuya ezindinganisweni ezihambisanayo.

(1) Ukuphathwa okusekelwe emvume, lapho opharetha emazingeni ahlukene benezimvume zokusebenza ezihlukene kanye nokufinyelela kumamenyu nokunye okuqukethwe. Lokhu akugcini nje ngokwenza lula, kusize, futhi kusheshise ukusebenza kwabaqhubi abajwayelekile, kodwa futhi kuvikela ngempumelelo uhlelo;

(2) Ukulinganisa isikhathi sangempela kanye nokuboniswa kwamandla okuhlola, inani eliphakeme kakhulu, ukugudluka, ukuguquguquka nezinye izimpawu; Ukuqoqwa kwesikhathi sangempela nokulawula kuye kwafinyelelwa endaweni yesikhulumi; Futhi kuzuzwe isikhathi esinembayo kanye namasampula anesivinini esikhulu;

(3) Ukuboniswa kwesikrini sesikhathi sangempela samajika okuhlola ahlukahlukene njengokuwohloka komthwalo nokususwa komthwalo kufinyelelwe, okungashintshwa futhi kubhekwe nganoma yisiphi isikhathi. Ukusondeza nokuphuma kwamajika kulula kakhulu;

(4) Ikhompyutha inemisebenzi efana nokugcina, ukusetha, nokulayisha amapharamitha okuhlola. I-Zeroing, ukulinganisa, neminye imisebenzi yenziwa ngesofthiwe, futhi ipharamitha ngayinye ingagcinwa kalula futhi ingeniswe, okwenza kube lula ukushintsha phakathi kwezinzwa eziningi kumsingathi ngaphandle komkhawulo enanini lezinzwa;

(5) Sekela izindlela zokulawula eziningi, okuhlanganisa ukugudluzwa kwesivinini okungaguquki kwe-loop, amandla esivinini angashintshi, ingcindezi yesivinini eqhubekayo, nezinye izindlela zokulawula iluphu evaliwe; Futhi unikeze amajika ereferensi ajwayelekile phakathi nenqubo yokulungisa iphutha yamapharamitha avaliwe ngama-opharetha athuthukile, ukuze abasebenzisi bakwazi ukubona umthelela wepharamitha ngayinye kumphumela weluphu evaliwe.

(6) Ifakwe isistimu yochwepheshe ehlakaniphile yokusetha izindlela zokulawula inqubo yokuhlola, ihlinzeka abasebenzisi abangochwepheshe ngabahleli bezinhlelo abazenzakalelayo. Abasebenzisi bangahlanganisa kalula izindlela zokulawula eziningi futhi balawule isivinini ngokuya ngezidingo zangempela nemithetho, futhi bathuthukise izinhlelo zokulawula ezifanelana nezidingo zabo. Isofthiwe yokulinganisa nokulawula izolawula ngokuzenzakalelayo inqubo yokuhlola ngokuya ngezilungiselelo zomsebenzisi.

(7) Hlaziya idatha ngokusebenzisa ikhompyutha yomuntu. Indlela yokucubungula ihlangabezana nezidingo zamazinga asetshenziswa kabanzi futhi ingakwazi ukubala ngokuzenzakalelayo amapharamitha wokusebenza ahlukahlukene njengemodulus enwebekayo, amandla esivuno, namandla aqinile angalingani. Kungase futhi kungenelele ngesandla ohlelweni lokuhlaziya ukuze kuthuthukiswe ukunemba kokuhlaziywa; Okunye ukucutshungulwa kwedatha nakho kungenziwa ngokuya ngamazinga anikezwe umsebenzisi.

(8) Idatha yokuhlola igcinwa kumafayela ombhalo ngemibuzo elula yabasebenzisi, futhi ingaqhutshekwa kusetshenziswa noma yimuphi umbiko wezohwebo ovamile noma isofthiwe yokucubungula amagama, kuyilapho kusiza ukudluliswa kwedatha nge-inthanethi;

(9) Ijika ledatha lenqubo yokuhlola lingarekhodwa futhi lilondolozwe, futhi ijika lingambozwa futhi liqhathaniswe ukuze kube lula ukuhlaziya okuqhathanisayo;

(10) Umbiko wokuhlola ungaphrintwa ngendlela edingwa umsebenzisi. Abasebenzisi bangakhetha okuqukethwe kombiko wolwazi oluyisisekelo, imiphumela yokuhlola, namajika okuhlola ukuhlangabezana nezidingo ezihlukahlukene;

(11) I-zeroing yedijithali kanye nokulinganiswa okuzenzakalelayo kwamandla okuhlola kanye nokuguqulwa kufinyelelwe, okwenza kube lula ukusebenza futhi kuthuthukisa ukuthembeka komshini. Izilungiselelo ezahlukahlukene zepharamitha zigcinwa ngendlela yefayela ukuze zilondolozwe kalula futhi zilulame;

(12) Ingasetshenziswa ohlelweni lokusebenza lwe-Win7. Ukulawulwa kwenqubo yokuhlola, izinguquko kujubane lokunyakaza kwe-crossbeam, okokufaka kwepharamitha, nokunye ukusebenza konke kungaqedelwa kusetshenziswa ikhibhodi noma igundane, kukwenze kube lula futhi kusheshe ukusetshenziswa;

(13) Ifakwe ukuvikelwa kokulayisha ngokweqile kanye nomsebenzi wokuvala shaqa okuzenzakalelayo, ingakwazi ukubona ngokuzenzakalelayo ukuphuka kwesampula bese ivala shaqa ngokuzenzakalelayo.

Ngokwezidingo ezihlukene zabasebenzisi, imisebenzi yesofthiwe engenhla ingase ilungiswe noma ilungiswe.

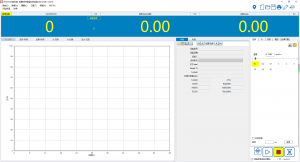

6. Isikhombikubona sokusebenza kwesofthiwe nesofthiwe:

(1) Isofthiwe ingasebenza ngohlelo lwe-Windows 7, futhi isixhumi esibonakalayo somsebenzisi sibonisa isistimu yewindi lesiShayina elihambisana nesitayela seWindows. Yonke imisebenzi yokuhlola ingaqedelwa ngokufaka igundane esikrinini sekhompyutha.

Isixhumi esibonakalayo esiyinhloko somshini wokuhlola

(Isixhumi esibonakalayo sesoftware sihluke kancane, ikakhulukazi sisekelwe eqinisweni)

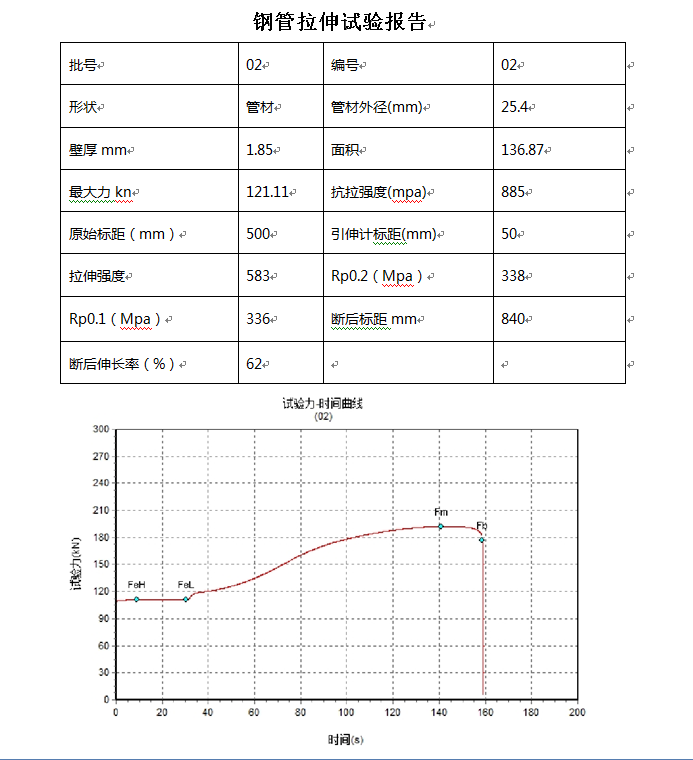

7. Umbiko wokuhlola:

Sesha futhi uphathe idatha yokuhlola ngamafayela edatha okuhlola; Enza ngendlela oyifisayo okuqukethwe nefomethi yemibiko yokuhlola ngokusebenzisa izilungiselelo zesifanekiso sombiko; Ngokuhlela amafomula nezinto zomphumela, ukusekelwa kwenani elikhulu lamazinga nezindlela zokuhlola kungafinyelelwa; Ngemva kokulayisha ifayela elilodwa noma amaningi edatha yokuhlola, khiqiza umbiko wokuhlola ngokwethempulethi yombiko bese uwuphrinta; Isekela izifanekiso zombiko we-Word ne-Excel, futhi zingahlelwa ngokukhululekile;

(Idatha ingeyereferensi kuphela futhi ayinakho ukubaluleka okungokoqobo)

8. Idivayisi yokuvikela ukuphepha

(1) Uma amandla okuhlola edlula u-2% -5% wamandla okuhlola aphezulu, ukuvikelwa kokulayisha ngokweqile kuyaqaliswa futhi uhlelo luyathululwa.

(2) Lapho ipiston ikhuphuka ifinyelela endaweni ephezulu yomkhawulo, isivikelo sohlangothi siyama futhi injini yepompo kawoyela iyama.

Ukusebenza okuyinhloko kanye nezinkomba zobuchwepheshe

| CHA. | Igama lephrojekthi | Amapharamitha |

| 1 | Ubuningi bamandla okuhlola i-kN | amakhulu ayisithupha |

| 2 | Isakhiwo sokusingatha | Izinsika ezine nezikulufu zokuhola ezimbili |

| 3 | Iphutha elihlobene lenkomba yamandla okuhlola | ≤ ± 1% yenani elibonisiwe |

| 4 | Ibanga lokulinganisa amandla okuhlola | 2% ~ 100% wamandla okuhlola aphezulu |

| 5 | Ibanga eliqhubekayo lokulawula ukucindezeleka kwesivinini (N/mm2 · S-1) | 2-60 |

| 6 | Ibanga lokulawula ubunzima obuqhubekayo | 0.00025/s~0.0025/s |

| 7 | Ibanga eliqhubekayo lokulawula ukufuduka kwesivinini (mm/min) | 0.5~50 |

| 8 | uhlelo lwe-clamping | I-hydraulic clamping |

| 9 | Ububanzi obuyindilinga besampula yokubopha ububanzi mm | Khetha noma iyiphi isethi ebangeni lika-Φ 6 kuya ku-Φ 40 |

| 10 | Isifanekiso esiyisicaba sokugoqa ububanzi ububanzi mm | 0~15 |

| 11 | Isifanekiso esiyisicaba sobubanzi be-clamping mm | amashumi ayisikhombisa |

| 12 | Isikhala esikhulu sokuhlola esiqinile mm | 550 (usayizi ungenziwa ngokwezifiso) |

| 13 | Isikhala esiphezulu sokuhlola ukucindezelwa mm | 500 (usayizi ungenziwa ngokwezifiso) |

| 14 | Lawula usayizi wangaphandle wekhabhinethi mm | 1100×620×850 |

| 15 | Ubukhulu bokusingatha ngamamilimitha | 900 × 630 × 2300 (usayizi ungenziwa ngokwezifiso) |

| 16 | Amandla emoto kW | amaphuzu amabili amathathu |

| 17 | Isisindo somsingathi kg | inkulungwane namakhulu amahlanu |

| 18 | Ibanga elimaphakathi lekholomu (mm) | amakhulu amane namashumi amahlanu |

| 19 | Usayizi wepuleti lomfutho ongaphezulu naphansi mm | Φ160 |

| 20 | Isikhala senduku yokugoba mm | 450 (usayizi ungenziwa ngokwezifiso) |

| 21 | Ububanzi benduku yokugoba mm | 140 (usayizi ungenziwa ngokwezifiso) |

| 22 | Idigri yokugoba evumelekile mm | 100 (usayizi ungenziwa ngokwezifiso) |

| 23 | Ubukhulu be-piston stroke mm | amakhulu amabili |

| 24 | Isivinini esikhulu sokunyakaza kwepiston mm/min | Cishe 60 |

| 25 | Isivinini sokulungiswa kwendawo yokuhlola mm/min | Cishe i-150 |

Ukucushwa okujwayelekile

| CHA. | Igama | Imininingwane | Qty. | amazwi |

| 1 | umsingathi |

| 1 Isethi | Uzikhiqizele wena |

| 2 | Umthombo kawoyela olawulwa yi-Servo |

| 1 Isethi | Uzikhiqizele wena |

| 4 | Ikhabhinethi yokulawula |

| 1 Isethi | Uzikhiqizele wena |

| 5 | Isistimu Yokulinganisa Nokulawula |

| 1 Isethi | Uzikhiqizele wena |

| 6 | Inzwa yokukhuluma isondo |

| 1 ama-pcs | Ukuhlola okubanzi |

| 7 | Yelula isifaki khodi |

| 1 ama-pcs | Jinan |

| 8 | ikhompuyutha |

| 1 Isethi | HP |

| 9 | iphrinta |

| 1 Isethi | HP |

| 10 | Isifanekiso esiyindilinga imihlathi mm | Khetha noma yimaphi amapheya phakathi kwebanga Φ 6- Φ 13, Φ 13- Φ 26, kanye Φ 26- Φ 40 | 1 ama-pcs | Uzikhiqizele wena

|

| 11 | Isampula lemihlathi eyisicaba mm | 0~15 | 1 ama-pcs | |

| 12 | Okunamathiselwe kokucindezelwa mm | Φ150 | 1 Isethi | Uzikhiqizele wena |

| 13 | Iphampu yamafutha |

| 1 Isethi | I-Mazzic, e-Italy |

| 14 | imishini kagesi |

| 1 Isethi | I-Shanghai Songhui |

| 15 | Imibhalo yobuchwepheshe | Imanuwali yomsebenzisi, uhlu lokupakisha, isitifiketi sokuvumelana | 1 ama-pcs | Uzikhiqizele wena |

Izinqubo zokusebenza:

Izinqubo zokusebenza zomshini wokuhlola i-electro-hydraulic servo

1. Qala ikhompuyutha bese ufaka isofthiwe

2. Qala ukushintsha kwamandla kanye neswishi eyinhloko yomthombo kawoyela yesilawuli se-servo se-electro-hydraulic

3. Lungisa i-crossbeam emaphakathi yomsingathi womshini wokuhlola ibe yindawo efanele, bese ushintsha indawo efanele ngokuya ngokuma, usayizi, nenjongo yokuhlola yesampula.

4. Vula ukushintsha kwamandla wepompo yamafutha bese uphakamisa isilinda samafutha somshini wokuhlola ukuze uqede isisindo sawo. (Ungakhetha isivinini sokususa esingu-10mm/min bese uchofoza inkinobho ethi [Phezulu] ukuze uphakamise isilinda kawoyela cishe ngo-1mm).

5. Faka ulwazi olufanele mayelana nesitayela kunguqulo yedatha yesofthiwe.

6. Ngemva kokubopha isitayela emhlathini ongenhla, setha kabusha inani lamandla libe uziro, lungisa i-crossbeam ephakathi nendawo ukuze ifike endaweni efanele, qinisa umhlathi ongezansi, bese usetha kabusha ukugudluka nokuguga. (Isitayela kufanele siboshwe ngaphezu kuka-80% wayo yonke imihlathi, futhi sigcinwe simile futhi siqondaniswe)

7. Khetha isivinini noma uhlelo olufanele, chofoza inkinobho ethi 【Qala】 kusofthiwe, bese uhlola.

Ngemva kokuphuka kwesampula, ukuhlolwa kuyaphela ngokuzenzakalelayo. Ukuze ubuke idatha yokuhlola, chofoza inguqulo yedatha kusofthiwe ukuze ubuke idatha edingekayo

Ngemva kokuphothulwa kwakho konke ukuhlolwa kwesampula, i-oil cylinder piston iwela phansi kusilinda kawoyela bese isishici esikhulu somthombo kawoyela sivaliwe.

8. Phuma kuhlelo lokusebenza, vala ikhompuyutha, bese uvala amandla osokhaya.

Qaphela:

1. I-iron shavings emihlathini yomshini wokuhlola kufanele isuswe njalo ukuze kugcinwe imihlathi ihlanzekile

Lapho uhlanza izinto zokusebenza nokugcina inhlanzeko endaweni yokusebenza, amandla kufanele anqanyulwe

Ngesikhathi sokuhlolwa, uma iphampu kawoyela iyeka ngokuzumayo ukusebenza, umthwalo osetshenzisiwe kufanele wehliswe, uhlolwe, futhi iphampu kawoyela kufanele iqalwe kabusha.

Lapho umshini wokuhlola umisiwe okwesikhashana, injini yepompo kawoyela kufanele ivalwe, futhi ibhentshi lokuhlola kufanele lehliswe ngemva kokuba ukuhlolwa kuqediwe. I-piston yesilinda samafutha akufanele iwele phansi kwesilinda futhi iphume ibanga elithile ukuze kube lula ukusetshenziswa kwesikhathi esizayo.

5. Gwema ukuvumela okokusebenza ukuthi kumanzi noma kuhlangane nezinto eziwuketshezi, futhi uvimbele okokusebenza ukuthi kunganyakaziswa noma kuthinteke.

6. Sicela ungaphumi egumbini lokuhlinzela bese ucindezela inkinobho yokumisa izimo eziphuthumayo esimweni esiphuthumayo

7. Gwema ukuphazamiseka kazibuthe

8. Abasebenzi bezobuchwepheshe abangaqeqeshiwe abavunyelwe ukushintsha uhlelo lwesofthiwe yomshini wokuhlola

Ukuqinisekisa ikhwalithi

Inkampani iqinisekisa ukuthi yonke imikhiqizo ikhiqizwa ngokuhambisana namazinga kazwelonke ahambisanayo;

Le nkampani iqinisekisa ukuthi zonke izesekeli zasekhaya zivela kumikhiqizo eyaziwayo enekhwalithi enhle kakhulu;

Inkampani iqinisekisa ukuthi zonke izesekeli zakwamanye amazwe ziyimikhiqizo yangempela neyiqiniso evela efektri;

Inkampani iqinisekisa ukuthi imikhiqizo enikezwa abasebenzisi iyimishini yoqobo emisha;

Inkampani iqinisekisa ukuthi yonke imikhiqizo ephuma efektri ihlolwa ngokuqinile ngokwezinqubo;

Inkampani ithembisa ukwamukela amakhasimende ukuthi avakashele futhi aqondise ifektri nganoma yisiphi isikhathi.

Izimo zokulungiselela umsebenzisi

Opharetha abanekhono ezinhlelweni zekhompyutha;

Umsebenzisi kufanele acacise izindlela zokuhlola kanye nemininingwane evamile ukuhlolwa okubhekiselwe kukho futhi okulandelwayo;

Nikeza amasampula ahlolwe kulo mshini ukuze ahlolwe umkhiqizo, ukuhlolwa kwefekthri, nokuhlolwa kokulungiswa komshini;

Isikhala, isisekelo, ukunikezwa kwamandla, njll. okudingekayo ekufakweni komkhiqizo;

Ilabhorethri kufanele ibe ne-air conditioning, izinga lokushisa lasendlini elilawulwa phakathi kuka-15-25 ℃ kanye nomswakama <70%;

Unesibopho sokwamukela, ukugcina, kanye nokuthutha imikhiqizo;

Ukusetshenziswa nokugcinwa

Abasebenzi bokuhlola abangaguquki nabaqeqeshiwe kufanele bahlelwe ukuthi basebenzise umkhiqizo, futhi abanye abavunyelwe ukuwusebenzisa;

Uma usebenzisa umkhiqizo, opharetha kufanele balandele ukuqeqeshwa neziqondiso abazitholile ukuze bawusebenzise ngenqubo efanele;

Ama-opharetha kufanele abe nekhono emazingeni okuhlola ahambisanayo ukuze anqume ngokunembile imiphumela yokuhlolwa;

Abasebenzisi kufanele bafunde ngokucophelela imanuwali yokusingatha kanye nemanyuwali yesofthiwe;

Ekupheleni kokuhlolwa, cisha umshini ngendlela efanele futhi unqamule yonke imithombo yamandla;

Uma kusetshenziswa izinto ezisizayo zokuhlola ezenziwe ngokwakho, isakhiwo sokuqala somkhiqizo akumele sishintshwe noma sonakaliswe ngesikhathi sokufakwa;

Uma kunesimo esingavamile noma ukwehluleka kukagesi ngesikhathi sokusebenza komshini wokuhlola, futhi inkinobho yokuqala noma yokumisa ingasebenzi, amandla kufanele anqanyulwe ngokushesha ukuze amise umshini wokuhlola ukuba usebenze;

I-screw kanye nezingxenye zokudlulisa kufanele zihlale zigcotshwa ngamafutha okugcoba ukuvimbela ukungqubuzana okomile;

Uma umkhiqizo ungasebenzi kahle, sicela uxhumane nomnyango wethu wenkonzo yamakhasimende ngesikhathi futhi ungawuqedi ngokuqondile ngaphandle kokugunyazwa;

Ungawushintshi umkhiqizo uwedwa.

I-SHANDONG DRICK ISTRUMENTS CO., LTD

Iphrofayela Yenkampani

I-Shandong Drick Instruments Co., Ltd, ibambe iqhaza kakhulu ocwaningweni nasekuthuthukisweni, ekukhiqizeni nasekuthengisweni kwezinsimbi zokuhlola.

Inkampani yasungulwa ngo-2004.

Imikhiqizo isetshenziswa kumayunithi ocwaningo lwesayensi, izikhungo zokuhlola ikhwalithi, amanyuvesi, ukupakisha, iphepha, ukuphrinta, irabha namapulasitiki, amakhemikhali, ukudla, imithi, izindwangu, nezinye izimboni.

U-Drick unaka ukukhuliswa kwethalente nokwakhiwa kweqembu, ukubambelela emcabangweni wokuthuthukiswa kobuchwepheshe, ukuzinikela.pragmatism, kanye nokusungula izinto ezintsha.

Ukunamathela esimisweni esigxile kumakhasimende, ukuxazulula izidingo eziphuthumayo nezisebenzayo zamakhasimende, futhi unikeze izixazululo ezisezingeni lokuqala kumakhasimende anemikhiqizo yekhwalithi ephezulu kanye nobuchwepheshe obuphambili.