I-DRK255–Ithuluzi Lokuhlola I-Hotplate Eligadiwe Ukujuluka

Incazelo emfushane:

Okokuqala, siyabonga kakhulu ngokuthenga i-DRK255 Sweating Guarded Hotplate, ngaphambi kokufaka nokusebenzisa, sicela ufunde leli bhukwana ngokucophelela, elingakusiza ukuthi umise ukusebenza futhi wenze imiphumela yokuhlolwa ibe lula. Ikhathalogi l Uhlolojikelele 1.1 Isingeniso Esifushane 1.2 Isicelo 1.3 Umsebenzi wensimbi 1.4 Indawo esetshenziswayo 1.4.1 Izinga lokushisa elizungezile nomswakama 1.4.2 Izidingo zamandla 1.4.3 Imithombo yokudlidliza, njll. 1.5 Izimiso zobuchwepheshe 1.6 Isimiso Sethulwa...

Okokuqala, ngiyabonga kakhulu ngokuthenga kwethuDRK255I-Sweating Guarded Hotplate, ngaphambi kokufaka nokusebenzisa, sicela ufunde leli bhukwana ngokucophelela, elingakusiza ukuthi umise ukusebenza futhi wenze imiphumela yokuhlolwa ibe lula.

Ikhathalogi

lUhlolojikelele

1.1 Isingeniso esifushane

1.2 Isicelo

1.3 Umsebenzi wezinsimbi

1.4 Sebenzisa indawo ezungezile

1.4.1 Izinga lokushisa elizungezile kanye nomswakama

1.4.2 Izidingo zamandla

1.4.3 Akukho eduze kwemithombo yokudlidliza, njll.

1.5 Imingcele yezobuchwepheshe

1.6 Isimiso Isingeniso

1.6.1 Incazelo kanye neyunithi yokumelana nokushisa

1.6.2 Incazelo kanye neyunithi yokumelana nomswakama

1.7 Isakhiwo sezinsimbi

1.8 Izici zezinsimbi

1.8.1 Iphutha eliphansi lokuphindaphinda

1.8.2 Ukwakheka okuhlangene nobuqotho obuqinile

1.8.3 Ukuboniswa kwesikhathi sangempela kwamanani “okumelana nokushisa nokuswakama”

1.8.4 Umphumela wokujuluka wesikhumba olingise kakhulu

1.8.5 Ukulinganisa okuzimele kwamaphuzu amaningi

1.8.6 Izinga lokushisa le-Microclimate kanye nomswakama kuyahambisana nezindawo zokulawula ezijwayelekile

lNgaphambi kokusebenzisa

2.1 Ukwamukelwa kanye nokuhlolwa

2.2 Ukufakwa

2.3 Vula amandla bese uyaqinisekisa

lUkusebenza

3.1 Izindlela zokuhlola kanye namazinga

3.2 Ukulungiselela ngaphambi kokuqala

3.3 Qalisa ukusebenza kokumelana nokushisa

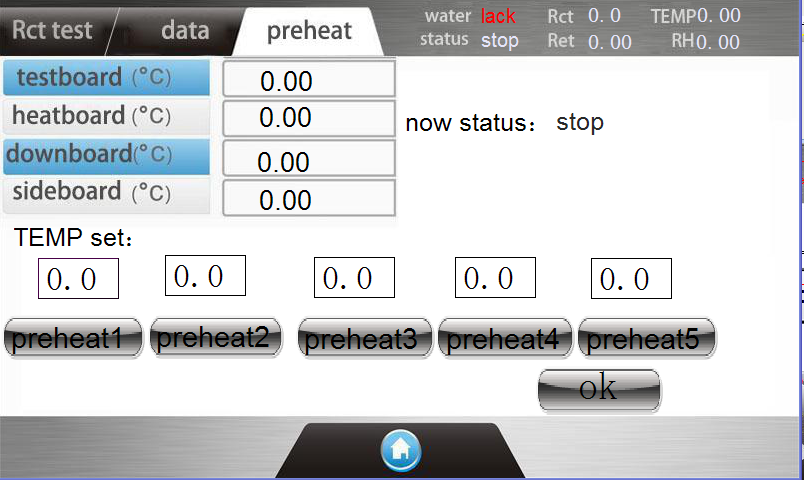

3.3.1 Ukushisa kuqala komshini

3.3.2 Ukusetha ukumelana nokushisa

3.3.3 Ukuhlolwa kwepuleti elingenalutho lokumelana nokushisa

3.3.4 Ukuhlola ukumelana nokushisa

3.3.5 Buka, phrinta futhi ususe ukumelana nokushisa

3.3.6 Ukulinganisa ukumelana nokushisa

3.3.7 Amasampula asebenzayo okumelana nokushisa

3.4 Qalisa ukusebenza kokumelana nomswakama

3.4.1 Ukushisa kuqala komshini

3.4.2 Ukusetha ukumelana nomswakama

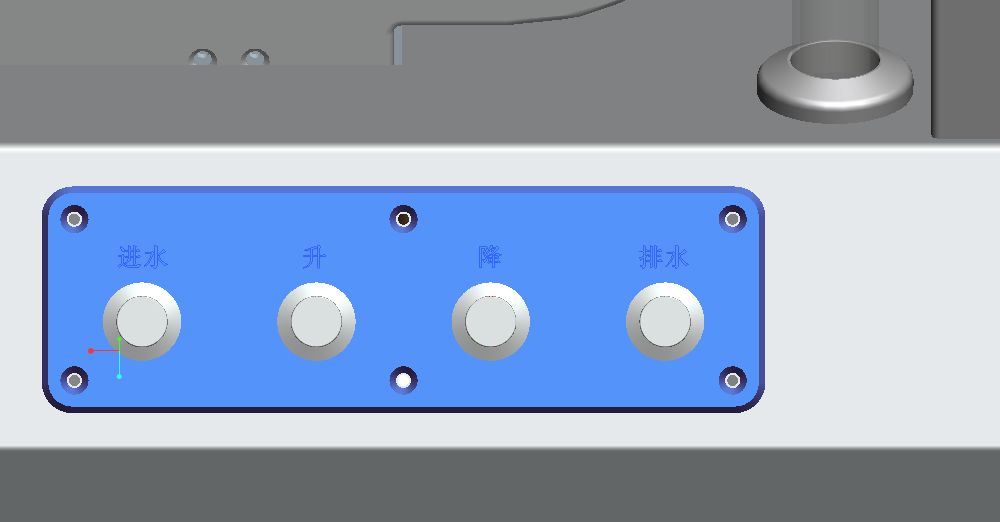

3.4.3 Umsebenzi wokuswakama nokugcwalisa amanzi

3.4.4 Ukuhlolwa kwepuleti elingenalutho lokumelana nomswakama

3.4.5 Ukuhlolwa kokumelana nomswakama

3.4.6 Ukubuka nokuphrinta ukumelana nomswakama

3.4.7 Ukulinganisa ukumelana nomswakama

3.4.8 Amasampula asebenzayo okumelana nomswakama

3.4.9 Ukuguqulwa kokumelana nomswakama kanye nokuhlola ukumelana nokushisa

lIzidingo zesampula

4.1 Isampula yokulawula ukuswakama

4.2 Ubuningi besampula nosayizi

4.3 Izidingo zokubekwa kwesampula

lUkubaluleka kokumelana nokushisa nomswakama

5.1 Ukubaluleka kokumelana nokushisa

5.2 Ukubaluleka kokumelana nomswakama

lUkusekela kwezobuchwepheshe

6.1 Ukuhlonza iphutha

6.2 Isondlo

lIzinkinga ezijwayelekile

7.1 Inkinga yesikhathi sokubona

7.2 Inkinga yosayizi wesampula

7.3 Ukuthi izinga lokushisa lokusetha lihlobene yini nevelu yokumelana nokushisa

7.4 Inkinga yenkomba etholiwe

7.5 Ukulinganiswa kwethuluzi kanye nezinkinga zesampula ezijwayelekile

l8. Isithasiselo: Isikhathi senkomba yokuhlola

Uhlolojikelele

1.1 Uhlolojikelele lwemanuwali

Imanuwali ihlinzeka ngohlelo lokusebenza lwe-DRK255 Sweating Guarded Hotplate, izimiso zokuthola eziyisisekelo kanye nezindlela eziningiliziwe zokusebenzisa, inikeza izinkomba zethuluzi nobubanzi bokunemba, futhi ichaza izinkinga ezithile ezivamile nezindlela zokwelapha noma iziphakamiso.

1.2 Ububanzi besicelo

I-DRK255 Sweating Guarded Hotplate ifanele izinhlobo ezahlukene zezindwangu zendwangu, okuhlanganisa izindwangu zezimboni, izindwangu ezingalukiwe nezinye izinto ezihlukahlukene eziyisicaba.

1.3 Umsebenzi wezinsimbi

Leli ithuluzi elisetshenziselwa ukukala ukumelana nokushisa (Rct) nokumelana nomswakama (Ret) kwezindwangu (kanye nezinye) izinto eziyisicaba. Leli thuluzi lisetshenziselwa ukuhlangabezana namazinga e-ISO 11092, ASTM F 1868 kanye ne-GB/T11048-2008.

1.4 Sebenzisa indawo ezungezile

Ithuluzi kufanele libekwe ngezinga lokushisa elizinzile kanye nomswakama, noma ekamelweni eline-air-conditioning evamile. Yiqiniso, kungaba kuhle kakhulu ekamelweni lokushisa elihlala njalo kanye nomswakama. Izinhlangothi ezingakwesokunxele nezingakwesokudla zensimbi kufanele zishiywe okungenani u-50cm ukwenza umoya ungene futhi uphume kahle.

1.4.1 Izinga lokushisa lendawo kanye nomswakama:

Ukushisa kwe-ambient: 10℃ kuya ku-30℃; Umswakama ohlobene: 30% kuya ku-80%, ovumela ukuzinza kwezinga lokushisa kanye nomswakama ekamelweni le-microclimate.

1.4.2 Izidingo zamandla:

Insimbi kufanele isekelwe kahle!

I-AC220V±10% 3300W 50Hz, umkhawulo ngokusebenzisa okwamanje ngu-15A. Isokhethi endaweni yokuphakela amandla kufanele ikwazi ukumelana namanje okungaphezu kuka-15A.

1.4.3Awukho umthombo wokudlidliza nxazonke, awukho indawo edlayo, futhi awukho ukugeleza komoya okungenelayo.

1.5 Ipharamitha yezobuchwepheshe

1. Ibanga lokuhlola ukumelana nokushisa: 0-2000×10-3(m2 •K/W)

Iphutha lokuphindaphinda lingaphansi kokuthi: ±2.5% (ukulawula kwefekthri kungaphakathi ±2.0%)

(Izinga elifanele lingaphakathi kuka-±7.0%)

Ukulungiswa: 0.1×10-3(m2 •K/W)

2. Ibanga lokuhlola ukumelana nomswakama: 0-700 (m2 •Pa / W)

Iphutha lokuphindaphinda lingaphansi kokuthi: ±2.5% (ukulawula kwefekthri kungaphakathi ±2.0%)

(Izinga elifanele lingaphakathi kuka-±7.0%)

3. Uhla lokulungiswa kwezinga lokushisa lebhodi lokuhlola: 20-40℃

4. Isivinini somoya ngaphezu kobuso besampula: Ukusetha okujwayelekile 1m/s (kuyalungiseka)

5. Ukuphakama kwesiteji (ukujiya kwesampula): 0-70mm

6. Ibanga lokusetha isikhathi sokuhlola: 0-9999s

7. Ukunemba kokulawula izinga lokushisa: ±0.1℃

8. Ukulungiswa kwenkomba yokushisa: 0.1℃

9. Isikhathi sangaphambi kokushisa: 6-99

10. Usayizi wesampula: 350mm×350mm

11. Usayizi webhodi lokuhlola: 200mm×200mm

12. Ubukhulu bangaphandle: 1050mm×1950mm×850mm (L×W×H)

13. Ukunikezwa kwamandla: AC220V±10% 3300W 50Hz

1.6 Isimiso Isingeniso

1.6.1 Incazelo kanye neyunithi yokumelana nokushisa

Ukumelana nokushisa: ukushisa okomile kugeleza endaweni ethile lapho indwangu isesilinganisweni sokushisa esizinzile.

Iyunithi yokumelana ne-thermal Rct iku-Kelvin ngewathi ngemitha yesikwele (m2·K/W).

Lapho ithola ukumelana nokushisa, isampula imbozwa ebhodini lokuhlola ukushisa kukagesi, ibhodi lokuhlola kanye nebhodi lokuvikela elizungezile kanye nepuleti eliphansi kugcinwa ezingeni lokushisa elifanayo lesethi (elifana no-35℃) ngokulawula ukushisa ngogesi, kanye nezinga lokushisa. inzwa idlulisela idatha kusistimu yokulawula ukuze kugcinwe izinga lokushisa elingaguquki, ukuze ukushisa kwepuleti lesampula kungahlakazwa kuphela phezulu (ngokuya ngasesampula), futhi zonke ezinye izikhombisi-ndlela zi-isothermal, ngaphandle kwamandla. ukushintshana. Ku-15mm endaweni engaphezulu yesikhungo sesampula, izinga lokushisa lokulawula lingu-20°C, umswakama ohlobene ngu-65%, futhi isivinini somoya esivundlile ngu-1m/s. Uma izimo zokuhlola zizinzile, uhlelo luzonquma ngokuzenzakalelayo amandla okushisa adingekayo ebhodini lokuhlola ukugcina izinga lokushisa elihlala njalo.

Inani lokumelana nokushisa lilingana nokumelana nokushisa kwesampula (umoya ongu-15mm, ipuleti lokuhlola, isampula) khipha ukumelana nokushisa kwepuleti elingenalutho (15mm umoya, ipuleti lokuhlola).

Insimbi ibala ngokuzenzakalelayo: ukumelana nokushisa, i-coefficient yokudlulisa ukushisa, inani le-Clo kanye nezinga lokulondoloza ukushisa

Qaphela: (Ngenxa yokuthi idatha yokuphindaphinda yensimbi ihambisana kakhulu, ukumelana nokushisa kwebhodi elingenalutho kudinga kuphela ukwenziwa kanye njalo ezinyangeni ezintathu noma isigamu sonyaka).

Ukumelana nokushisa: Rct: (m2·K/W)

Tm ——izinga lokushisa lebhodi lokuhlola

Ta ——ihlola izinga lokushisa lekhava

A —— indawo yebhodi lokuhlola

I-Rct0——ibhodi elingenalutho lokumelana nokushisa

H —— ibhodi lokuhlola amandla kagesi

△Hc— ukulungiswa kwamandla okufudumeza

I-coefficient yokudlulisa ukushisa: U =1/ Rct(W/m2·K)

Isiqephu:CLO=10.155·U

Izinga lokulondoloza ukushisa: Q=Q1-Q2Q1×100%

Q1 (Ayikho isampula yokukhishwa kokushisa (W/℃)

Q2 -Ngesampula yokukhishwa kokushisa (W/℃)

Qaphela:(Inani le-Clo: ekamelweni lokushisa elingu-21℃, umswakama ohlobene ≤50%, ukugeleza komoya 10cm/s (akukho moya), ogqokile uhlezi anganyakazi, futhi i-basal metabolism yayo ingu-58.15 W/m2 (50kcal/m2·h), zizwe ukhululekile futhi ulondoloze izinga lokushisa elijwayelekile lendawo yomzimba ku-33 ℃, inani le-insulation lezingubo ezigqokwe ngalesi sikhathi liyinani elingu-1 Clo (1 CLO=0.155℃·m2/W)

1.6.2 Incazelo kanye neyunithi yokumelana nomswakama

Ukumelana nomswakama: ukugeleza kokushisa kokuhwamuka endaweni ethile ngaphansi kwesimo somoya ozinzile wokucindezela komhwamuko wamanzi.

Iyunithi yokumelana nomswakama i-Ret iku-Pascal ngewathi ngemitha yesikwele (m2·Pa/W).

Ipuleti lokuhlola nepuleti lokuvikela kokubili amapuleti ensimbi akhethekile anezimbotshana, ambozwe ngefilimu encane (engakwazi ukungena kuphela emhwamukeni wamanzi kodwa hhayi amanzi awuketshezi). Ngaphansi kokushisisa kukagesi, izinga lokushisa lamanzi acwengekile elinikezwa uhlelo lokuphakelwa kwamanzi likhuphukela enanini elimisiwe (elifana no-35℃). Ibhodi lokuhlola kanye nebhodi elizungezile lokuvikela kanye nepuleti eliphansi konke kugcinwa ezingeni lokushisa elimisiwe elifanayo (elifana no-35°C) ngokulawulwa kokushisa ngogesi, futhi inzwa yezinga lokushisa idlulisela idatha kusistimu yokulawula ukuze kugcinwe izinga lokushisa elingashintshi. Ngakho-ke, amandla okushisa komhwamuko wamanzi ebhodi lesampula angaba phezulu kuphela (ngasendleleni yesampula). Awukho umhwamuko wamanzi nokushintshana kokushisa kwezinye izindawo,

ibhodi lokuhlola kanye nebhodi layo lokuvikela elizungezile kanye nepuleti eliphansi konke kugcinwa ezingeni lokushisa elimisiwe elifanayo (elifana no-35 ° C) ngokushisisa ngogesi, futhi inzwa yokushisa idlulisela idatha ohlelweni lokulawula ukuze kugcinwe izinga lokushisa elingashintshi. Amandla okushisa umhwamuko wamanzi epuleti lesampula angasatshalaliswa phezulu kuphela (ngokuya ngasesifanekiso). Akukho ukushintshana kwamandla okushisa komhwamuko kwezinye izinkomba. Izinga lokushisa elingu-15mm ngaphezu kwesifanekiso lilawulwa ku-35℃, umswakama ohlobene ngu-40%, futhi isivinini somoya ovundlile ngu-1m/s. Indawo ephansi yefilimu inomfutho wamanzi ogcwele we-5620 Pa ku-35 ℃, futhi indawo engaphezulu yesampula inomfutho wamanzi we-2250 Pa ku-35 ℃ kanye nomswakama ohlobene no-40%. Ngemuva kokuthi izimo zokuhlola zizinzile, uhlelo luzonquma ngokuzenzakalelayo amandla okushisa adingekayo ebhodini lokuhlola ukugcina izinga lokushisa elihlala njalo.

Inani lokumelana nomswakama lilingana nokumelana nomswakama wesampula (umoya ongu-15mm, ibhodi lokuhlola, isampula) kukhishwe ukumelana nomswakama webhodi elingenalutho (umoya ongu-15mm, ibhodi lokuhlola).

Insimbi ibala ngokuzenzakalelayo: ukumelana nomswakama, inkomba yokungena komswakama, nokungena komswakama.

Qaphela: (Ngenxa yokuthi idatha yokuphindaphinda yensimbi ihambisana kakhulu, ukumelana nokushisa kwebhodi elingenalutho kudinga kuphela ukwenziwa kanye njalo ezinyangeni ezintathu noma isigamu sonyaka).

Ukumelana nomswakama: Ret Pm——Umfutho womhwamuko ogcwele

I-Pa——Umfutho wamanzi womhwamuko wegumbi lesimo sezulu

H——Ibhodi lokuhlola amandla kagesi

△Yena—Inani lokulungisa lamandla kagesi ebhodi lokuhlola

Inkomba yokungena komswakama: imt=s*Rct/RetS— 60 ka/k

Umswakama ongenamanzi: Wd=1/(Ret*φTmg/(m2*h*pa)

φTm—Ukushisa okucashile komhwamuko wamanzi ongaphezulu, laphoTm ngi 35℃时,φTm=0.627 W*h/g

1.7 Isakhiwo sezinsimbi

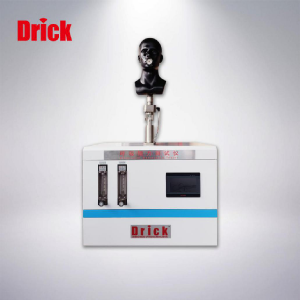

Ithuluzi lakhiwe izingxenye ezintathu: umshini oyinhloko, uhlelo lwe-microclimate, isibonisi nokulawula.

1.7.1Umzimba oyinhloko ufakwe isampula lepuleti, ipuleti lokuvikela, nepuleti eliphansi. Futhi ipuleti ngalinye lokushisa lihlukaniswa yinto evimbela ukushisa ukuze kuqinisekiswe ukuthi akukho ukudlulisa ukushisa phakathi komunye nomunye. Ukuze kuvikelwe isampula emoyeni ozungezile, kufakwa isembozo se-microclimate. Kukhona umnyango wengilazi wemvelo obonakalayo phezulu, futhi inzwa yokushisa neyomswakama yegumbi lokuhlola ifakiwe kukhava.

1.7.2 Uhlelo lokubonisa kanye nokuvimbela

Ithuluzi lamukela isikrini esihlanganisiwe se-weinview touch display, futhi ilawula isistimu ye-microclimate kanye nomsingathi wokuhlola ukuze asebenze futhi ame ngokuthinta izinkinobho ezihambisanayo esikrinini sokubonisa, idatha yokulawula okokufaka, kanye nedatha yokuhlola okukhiphayo yenqubo yokuhlola nemiphumela.

1.8 Izici zezinsimbi

1.8.1 Iphutha eliphansi lokuphindaphinda

Ingxenye eyinhloko ye-DRK255 uhlelo lokulawula ukushisa iyithuluzi elikhethekile elicwaningwe ngokuzimela futhi lathuthukiswa. Ngokwethiyori, iqeda ukungazinzi kwemiphumela yokuhlolwa okubangelwa inertia eshisayo. Lobu buchwepheshe benza iphutha lokuhlola okuphindaphindwayo libe lincane kakhulu kunezindinganiso ezifanele ekhaya naphesheya. Iningi lamathuluzi okuhlola "ukusebenza kokudlulisa ukushisa" anephutha lokuphindaphinda cishe elingu-±5%, futhi inkampani yethu isifinyelele ku-±2%. Kungashiwo ukuthi ixazulule inkinga yomhlaba yesikhathi eside yamaphutha amakhulu okuphindaphinda ezinsimbini zokushisa ezishisayo futhi yafinyelela ezingeni eliphezulu lamazwe ngamazwe. .

1.8.2 Ukwakheka okuhlangene nobuqotho obuqinile

I-DRK255 iyisisetshenziswa esihlanganisa umsingathi kanye ne-microclimate. Ingasetshenziswa ngokuzimela ngaphandle kwamadivayisi angaphandle. Ivumelana nezimo zemvelo futhi ithuthukiswe ngokukhethekile ukunciphisa izimo zokusebenzisa.

1.8.3 Ukuboniswa kwesikhathi sangempela kwamanani “okumelana nokushisa nokuswakama”

Ngemuva kokuthi isampula ishiswe kuze kube sekugcineni, yonke inqubo yokuzinzisa inani "lokushisa okushisayo nokumelana nomswakama" ingaboniswa ngesikhathi sangempela. Lokhu kuxazulula inkinga yesikhathi eside yokuhlolwa kokumelana nokushisa nomswakama kanye nokungakwazi ukuqonda yonke inqubo.

1.8.4 Umphumela wokujuluka wesikhumba olingise kakhulu

Ithuluzi linomphumela wokujuluka wesikhumba somuntu (ofihliwe), ohlukile ebhodini lokuhlola elinezimbobo ezimbalwa kuphela. Yenelisa ukucindezela okulinganayo komhwamuko wamanzi yonke indawo ebhodini lokuhlola, futhi indawo yokuhlola ephumelelayo inembile, ukuze “ukungamelani komswakama” okukaliwe kusondele kunani langempela.

1.8.5 Ukulinganisa okuzimele kwamaphuzu amaningi

Ngenxa yohlu olukhulu lokuhlola ukumelana nokushisa nomswakama, ukulinganisa okuzimele kwamaphuzu amaningi kungathuthukisa ngempumelelo iphutha elibangelwa ukungahambisani nomugqa futhi kuqinisekise ukunemba kokuhlolwa.

1.8.6 Izinga lokushisa le-Microclimate kanye nomswakama kuyahambisana nezindawo zokulawula ezijwayelekile

Uma kuqhathaniswa nezinsimbi ezifanayo, ukwamukela izinga lokushisa le-microclimate kanye nomswakama ohambisana nendawo yokulawula evamile kuhambisana kakhulu "nendlela evamile", futhi izidingo zokulawula i-microclimate ziphakeme.

Ngaphambi kokusebenzisa

Incazelo yokuqukethwe kulesi sigaba ihlanganisa isifinyezo sokuqala esisheshayo ukuze sikusize uqonde ngokushesha. Lokhu kuzokuqondisa ekusetheni, ukulinganisa nokusebenza okuyisisekelo kwethuluzi. Kunconywa ukuthi uqale ukufunda le ngxenye ngemva kokuphequlula okuqukethwe kwangaphambilini.

2.1 Ukwamukelwa kanye nokuhlolwa

Vula ibhokisi bese ukhipha wonke umshini ukuze uhlole umonakalo osobala.

Bala ngokohlu lokupakisha, imiyalelo yokusebenza nezisekeli.

2.2 Ukufakwa

2.2.1Lungisa izinyawo ezine ukuze ubeke phakathi nendawo ibhamuza elivundlile elakhelwe ngaphakathi ukuze uqinisekise izinga lebhodi lokuhlola.

2.2.2 Izintambo

Xhuma ingxenye eyodwa yekhebula yekhompiyutha kusokhethi yekhompiyutha yensimbi kanye nohlangothi olulodwa kukhompuyutha (uyazikhethela)

2.3 Vula amandla bese uyaqinisekisa

Vula amandla bese ubheka ukuthi isibonisi sijwayelekile yini.

Ukusebenza

3.1 Izindlela zokuhlola kanye namazinga

ISO 11092, ASTM F 1868, GB/T11048-2008

3.2 Ukulungiselela ngaphambi kokuqala

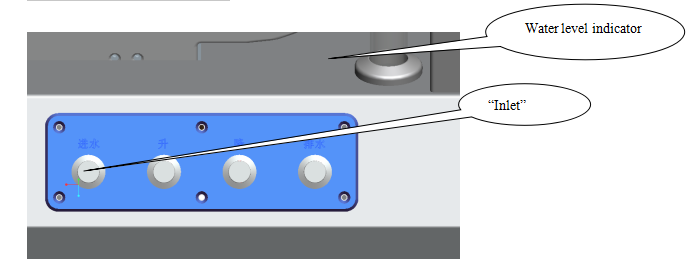

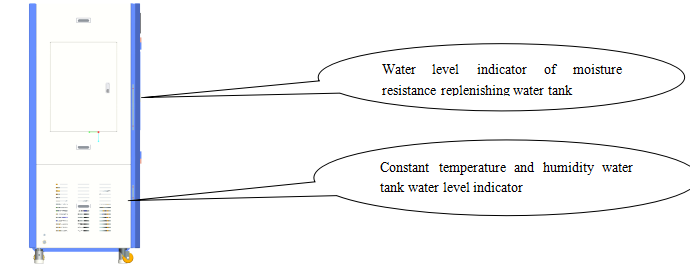

3.2.1Ngaphambi kokuqala umshini, hlola ukuthi akhona yini amanzi anele enkombeni yezinga lamanzi lokushisa okungashintshi kanye nomswakama ithangi lamanzi. Uma amanzi engekho, sicela ungeze amanzi kuqala. Uma kungenjalo, ngisho noma ivuliwe, izinga lokushisa elihlala njalo kanye nomswakama ngeke kusebenze. Indlela yokwengeza amanzi: Vula umnyango wangaphambili, ukhulule isembozo sensimbi engagqwali ngakwesobunxele, thatha ifaneli ye-accessory, futhi uthele amanzi amaminerali (amanzi acwecwe anconywa) ukuze unikeze ukulungiswa kwe-microclimate humidity. Thela amanzi phakathi kwemigqa yenkomba yezinga lamanzi.

3.2.2Sicela uqinisekise ukuthi akhona yini amanzi esibonisini sezinga lamanzi sokumelana nomswakama ogcwalisa ithangi lamanzi engxenyeni engenhla kwesokunxele, bese unikeza ukuhlolwa kokumelana nomswakama. Indlela yokusebenza: bheka entweni 3.4.3 [Ukusebenza kokuswakama nokugcwaliswa kabusha kanye nokusebenza kokuhlolwa kokufakwa kwefilimu]Qaphela:Leli thangi lamanzi kufanele ligcwaliswe ngamanzi acwecwe.

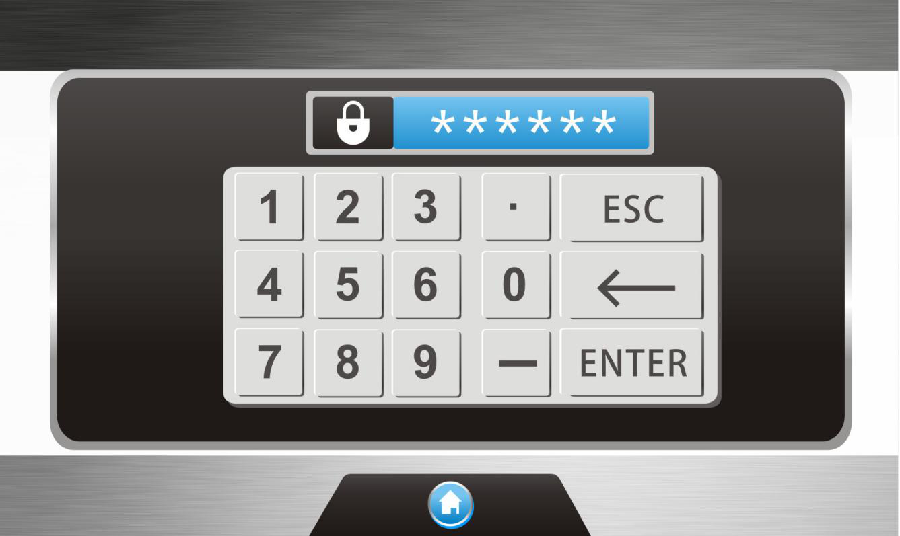

3.2.3 Isingeniso sekhasi kanye nokuhlelwa kwepharamitha

Izinga lokushisa eliqhubekayo nomswakama; ngemva kokuvula amandla, isixhumi esibonakalayo sokungena esilandelayo siyaboniswa:

Chofoza inkinobho ethi "Ngena" ukuze ufake iphasiwedi

Ngemva kokufaka okulungile, kuzobonisa:

I-interface eyinhloko inezinto ezi-4: ukuhlola, ukusetha, okulungile kanye nedatha.

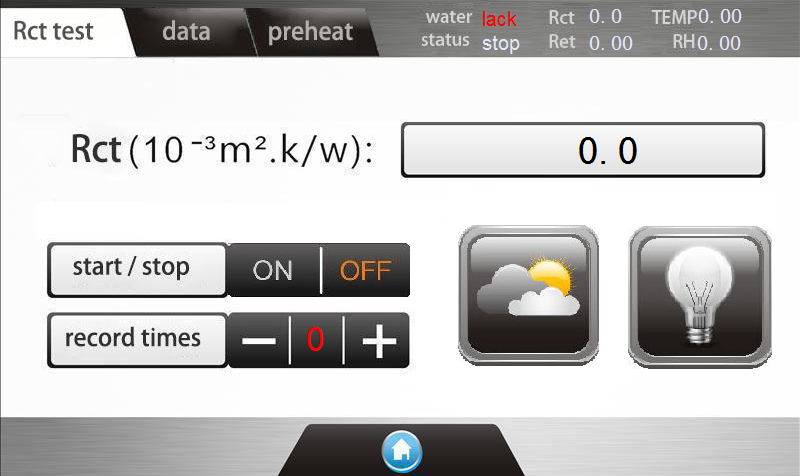

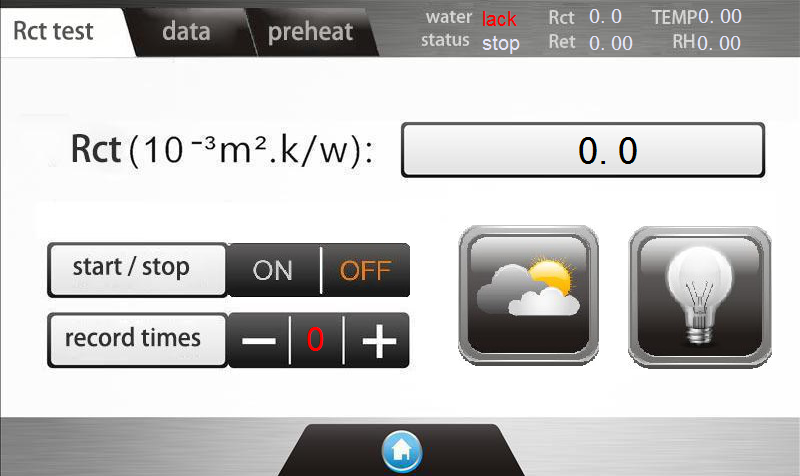

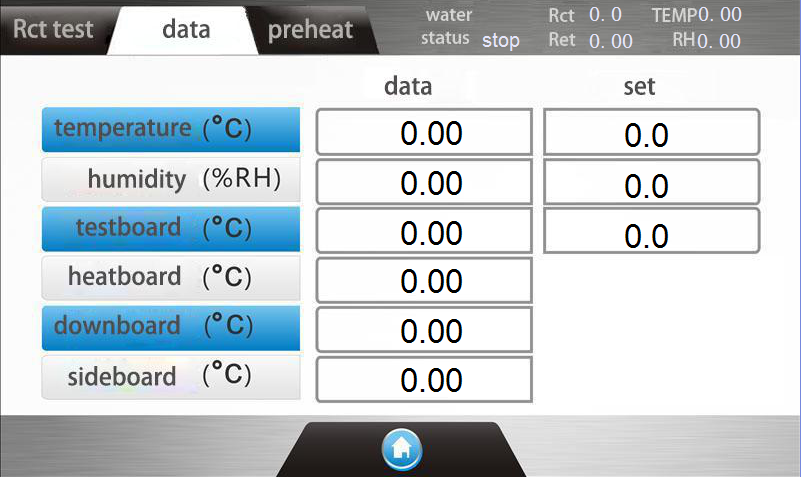

Ukuhlola: I-interface yokuhlola isetshenziselwa ukufaka ukumelana nokushisa noma isilingo sokumelana nomswakama, nokuvula noma ukuvala isistimu yesiqandisi nokukhanyisa.

Cindezela inkinobho yokulawula isiqandisi kuMfanekiso 305-1 ukuze uvule noma uvale isiqandisi futhi uqale izinga lokushisa elingashintshi kanye nesistimu yomswakama futhi ulawule ukukhanya; Idatha ye-Figure 305-2 yesikhathi sangempela yokusebenza; Umfanekiso 305-3 umshini obandayo wokushisa umsebenzi;

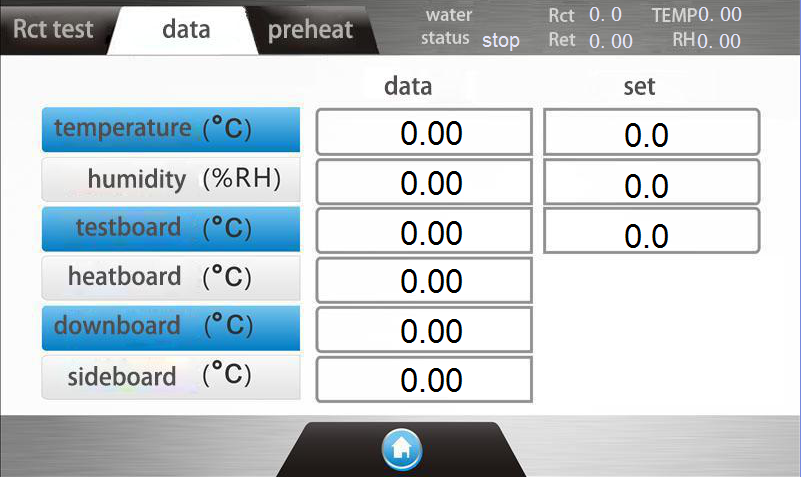

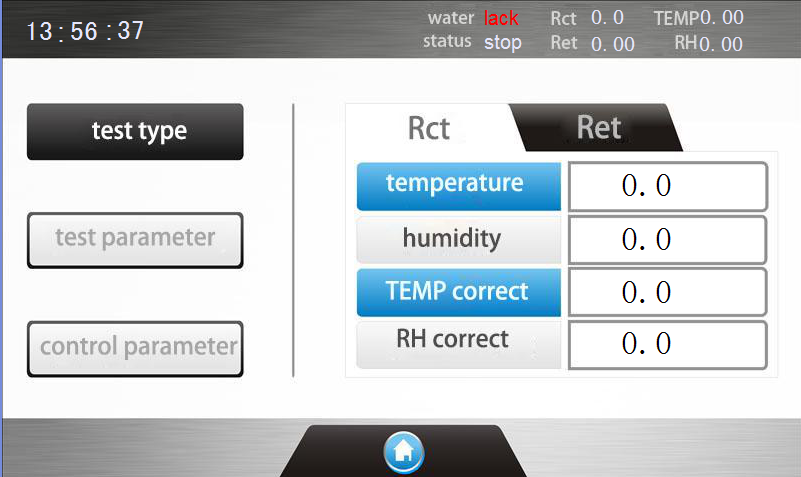

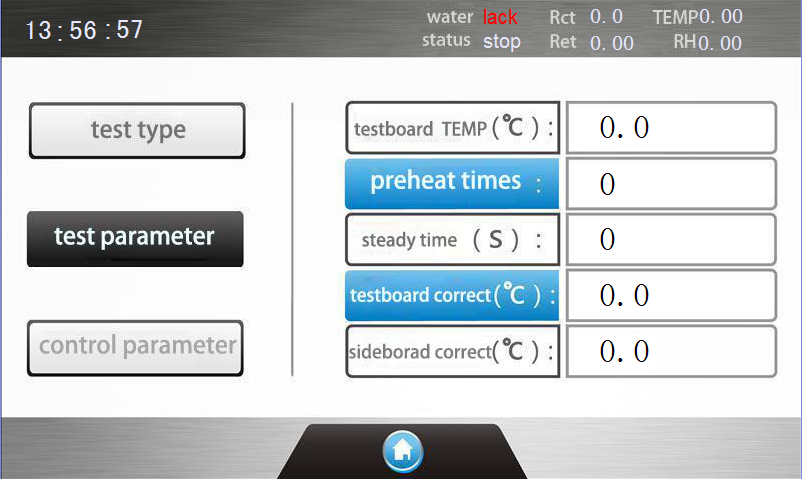

Ukusetha: isetshenziselwa ukusetha imingcele yokuhlola kanye nezinga lokushisa nomswakama nemingcele yemvelo yesimo sezulu

Izilungiselelo zepharamitha yezinga lokushisa nokuswakama:

Lapho ukhetha ukumelana nokushisa, uhlelo luzosetha ngokuzenzakalelayo izinga lokushisa le-microclimate libe ngu-20 ℃ kanye nomswakama ube ngu-65%;

Uma ukhetha ukumelana nomswakama, uhlelo luzomisa ngokuzenzakalelayo izinga lokushisa le-microclimate libe ngu-35 ° C nomswakama ube ngu-40%;

Abasebenzisi bangaphinda basethe amanye amapharamitha okushisa nokuswakama ngokuya ngezimo zangempela.

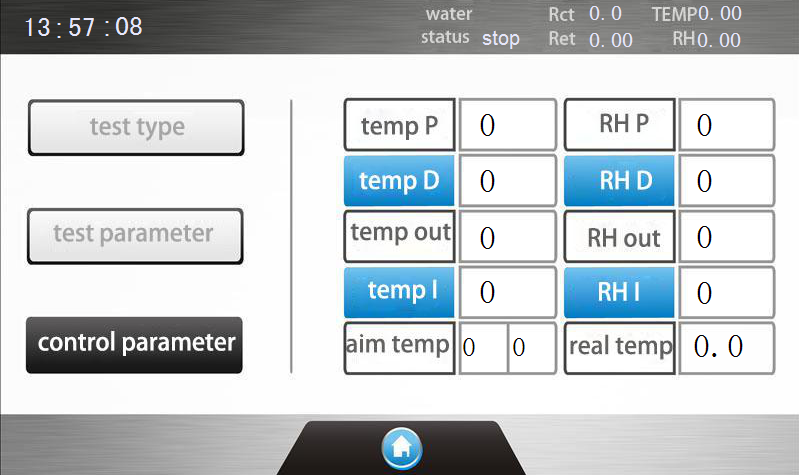

Izilungiselelo zepharamitha yokulawula izinga lokushisa nomswakama endaweni yokugcina impahla:

Isixhumi esibonakalayo sokusetha ipharamitha yokulawula izinga lokushisa nomswakama, le ngxenye yepharamitha isethiwe ngaphambi kokushiya imboni, umsebenzisi ngokuvamile akadingi ukusetha le nto, uma kunesidingo, uchwepheshe wefekthri angayisetha.

Ukulungiselelwa kwepharamitha yokumelana nokushisa nomswakama:

Ngokwezinga lokushisa, izinga lokushisa lebhodi lokuhlola lisethelwe ku-35 ℃, umjikelezo wokushisa kuqala uvamise ukuba izikhathi eziyisi-6, futhi isikhathi sokuhlola amasekhondi angu-600 (lokhu ukulungiselelwa okuzenzakalelayo okujwayelekile, njengokuhlola kokuqala kwesampula noma isivivinyo sesampula esishubile).

Phrinta: isetshenziselwa ukubuza nokuphrinta idatha, nokususa amarekhodi

I-Rct Ilungile: isetshenziselwa ukulinganisa idatha yokumelana nokushisa

3.3 Qalisa ukusebenza kokumelana nokushisa

Okokuqala hlola ukuthi ibhodi lokuhlola lome ngokuphelele yini (uma limanzi, sicela ubhekisele ekusebenzeni okungu-3.4.9).

3.3.1 Ukushisa kuqala komshini

Ngemva kokuvula amandla, wonke umshini udinga ukushisisa cishe imizuzu engama-45, lapho kufakwa indwangu enogqinsi olumaphakathi epuletini elinembobo. Lapho ipuleti yokuhlola ifinyelela ku-35 ° C, indwangu iyakhishwa, bese izinga lokushisa lepuleti lokushisa kanye nepuleti eliphansi libhekwa ukuze lifinyelele cishe ku-35.2 ukuqedela ukupholisa. Ngemuva kokuthi umshini usushisiwe, isampula yokuhlola (noma isampula evamile) ingafakwa ebhentshini lokuhlola.

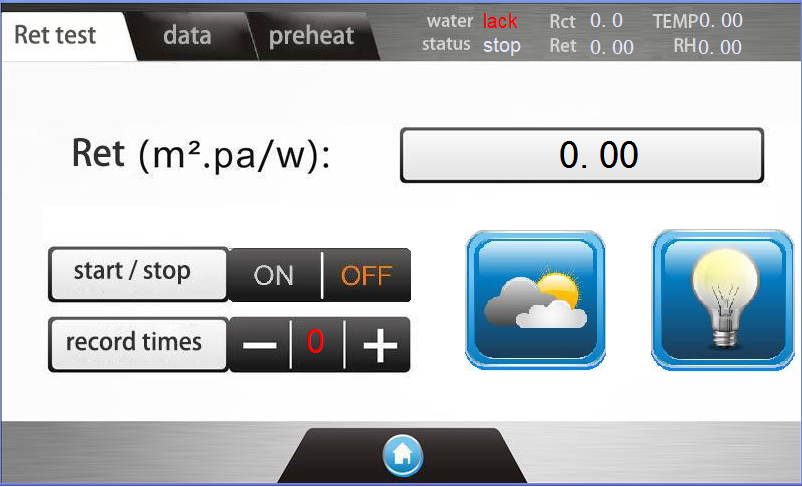

3.3.2 Ukusetha ukumelana nokushisa Bheka uMdwebo 309

Setha amapharamitha kusilungiselelo sepharamitha bese ucindezela okuthi “Test” ukuze ufake ukuhlolwa kwe-“thermal resistanc”

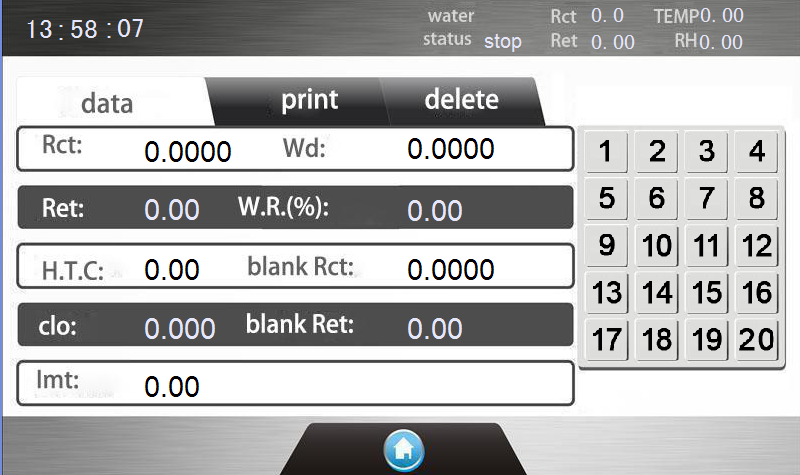

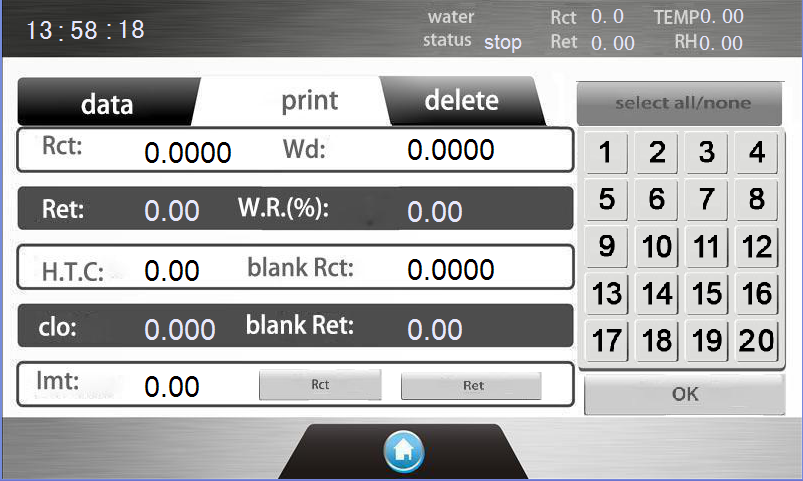

I-interface yokuhlola ibonisa njengoba kukhonjisiwe kuMfanekiso 314:

3.3.3 Ukuhlolwa kwepuleti elingenalutho lokumelana nokushisa

Ngaphambi kokuhlolwa, akumele kube “nesampula yokumelana nokushisa” - ukumelana nokushisa kwepuleti elingenalutho.

Ukumelana okushisayo kwepuleti elingenalutho ukumelana nokushisa kwensimbi ngokwayo ngaphandle kwesampula.

Kusixhumi esibonakalayo "sokusebenza kokumelana ne-thermal", khetha "izikhathi zokuhlola" ukuya ku-0 bese ucindezela "qala" ukuze wenze "ukuhlolwa kwepuleti elingenalutho lokumelana nokushisa". Ukulandelana kokuhlola: preheat-stable-test-stop (thola ukumelana nokushisa kwebhodi elingenalutho futhi ukugcine ngokuzenzakalelayo)

Qaphela:"Ukumelana nokushisa kwebhodi okungenalutho" kunconywa ukuba kwenziwe kanye ngoMashi kuya kuJuni. Ngenxa yokuthi iphutha lokuphindaphinda lokuhlolwa kwebhodi elingenalutho laleli thuluzi lincane kakhulu, akudingekile ukuqala ibhodi elingenalutho ukumelana nokushisa nsuku zonke.

3.3.4 Ukuhlola ukumelana nokushisa

Ku-interface "ye-thermal resistance operation".

Ngemva kokuhlangabezana nesicelo esingu-3.3.1, beka isampula ebusweni bepuleti elinembobo, lungisa inkinobho ethi “phezulu naphansi” phambi kwebhentshi lokuhlola ngaphakathi kwegumbi lokuhlola, bese uvala izinhlangothi ezine zesibambi sensimbi, lapho isibambi sensimbi sisendaweni evundlile ncamashi. Beka phansi ikhava ye-plexiglass, vala umnyango wensimbi, cindezela inkinobho "qala", futhi ithuluzi lizosebenza ngokuzenzakalelayo.

Ukulandelana okusebenzayo: preheat-stable-test-stop, bonisa ukumelana nokushisa kokuqala nezinye izinkomba.

Qaphela:Ngemva kokubonisa "izinzile", uma umsebenzisi ecabanga ukuthi idatha ithembekile futhi ayidingi ukuqhubeka nokuhlola, ungacindezela inkinobho ethi "stop", futhi ithuluzi lizogcina inani lokumelana nokushisa elibonisiwe njengomphumela wokuhlola.

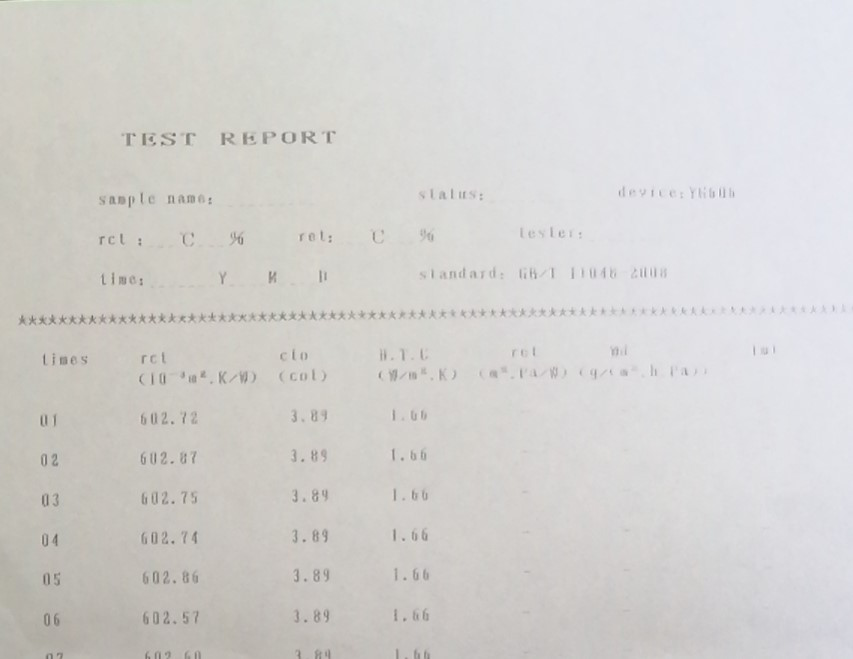

Shintsha isampula, cindezela u-2 ukuze uthole "izikhathi zokurekhoda" ukuze uhlole isampula yesibili, njalonjalo. Umbiko wokuhlola ungaphrintwa ngemva kokuhlolwa oku-3 ngokwendlela evamile.

3.3.5 Buka, phrinta futhi ususe ukumelana nokushisa

Cindezela okuthi “Phrinta” ukuze ubonise isixhumi esibonakalayo “sombuzo wedatha kanye nokuphrinta”, njengoba kukhonjisiwe kuMfanekiso 317.

Cindezela inkinobho ethi “KULUNGILE” futhi, futhi ithuluzi lizophrinta ngokuzenzakalelayo umbiko wokuhlola ukumelana nokushisa, njengoba kukhonjisiwe kuMfanekiso 318.

Shintshela kusixhumi esibonakalayo sokususa, khetha irekhodi elizosuswa, bese ucindezela okuthi “KULUNGILE”, idatha yokuhlola ekhethiwe manje izosuswa, futhi indawo yayo izothathelwa indawo idatha yokuhlola elandelayo.

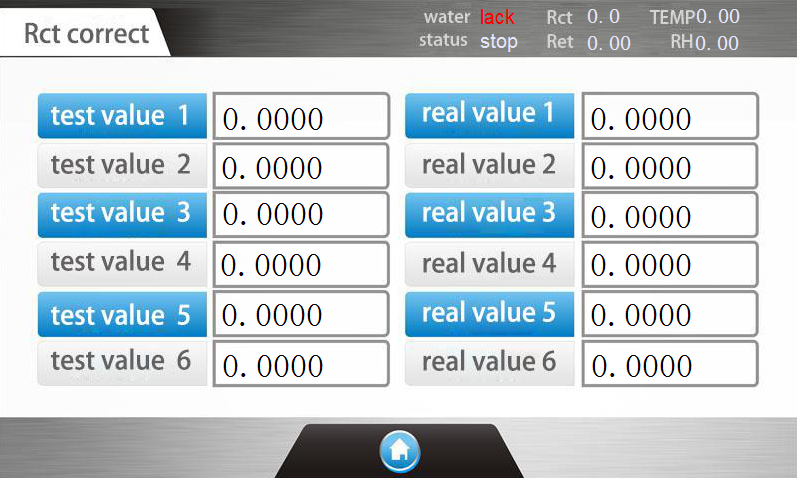

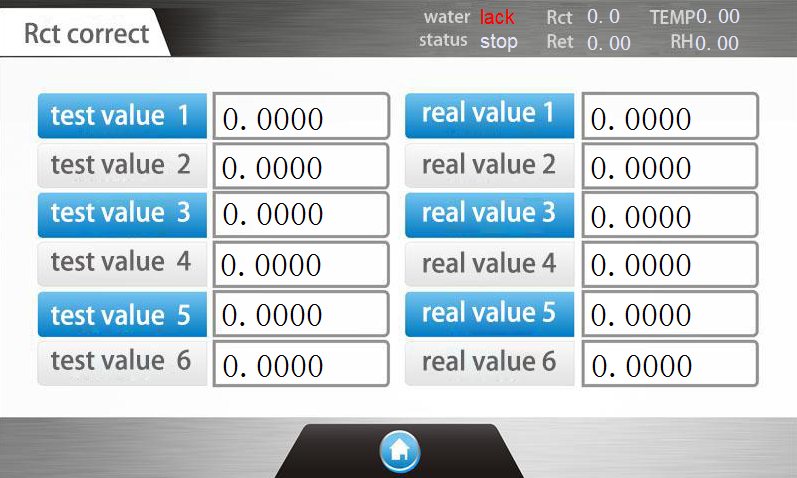

3.3.6 Ukulinganisa ukumelana nokushisa

Kunconywa ukwenza lokhu uma umshini omusha, noma ulinganiswe kanye njalo ezinyangeni eziyisithupha, nalapho inani lingavamile.

3.3.6.1 Faka isampula elijwayelekile lesipontshi (isampula elijwayelekile elinenani lokungazweli okushisayo) elinikezwe ezinsizeni zensimbi ebhentshini lokuhlola.

3.3.6.2 Hlola imiphumela yokuhlolwa kanye nemiphumela evamile ngaphansi kwekhasi lokulinganisa ukumelana nokushisa ukuze uqinisekise ukuthi yonke idatha inguziro.

3.3.6.3 Kusixhumi esibonakalayo sokuhlola ukumelana nokushisa, khetha “isikhathi sokurekhoda 1” bese ucindezela inkinobho ethi “Qala”.Qaphela:Udinga futhi ukuhlangabezana nesigatshana 3.3.1 ngaphambi kokucindezela inkinobho ethi “Qala”.

Ngesikhathi sokuhlolwa kokumelana nokushisa, ikhona eliphezulu kwesokudla sekhasi elifanayo kuqala libonisa "Preheat", "Stable", "Test", "Stop", kanye "nesikhathi sokurekhoda 1", ukuphela kokuhlolwa.

3.3.6.4 Bese ufaka amasampula ajwayelekile wesipontshi sobunye ugqinsi, bese ukala imiphumela yokuhlolwa “yesikhathi sokurekhoda 12” kanye “nesikhathi sokurekhoda 3” njengaku-3.3.6.1 kuya ku-3.3.6.3.

3.3.6.5 Faka amanani alinganisiwe okumelana nokushisa amasampula ajwayelekile wesipontshi sogqinsi obuhlukene ezintweni ezihambisanayo “Zemiphumela Yokuhlola”, bese ufaka “amanani edatha avamile” kumasampula ajwayelekile ahambisanayo ezintweni ezihambisanayo "Zomphumela Ojwayelekile" .

Umsebenzisi angaphinda akhethe izinga elilodwa kuphela noma amabili okujiya ukuze alinganise, futhi afake okuthi "0" kokunye. Qaphela: Kusixhumi esibonakalayo "Sokulinganiswa Kokumelana Nokushisa", faka idatha yesampula yesipontshi esilinganisiwe ukusuka kwencane ukuya kwenkulu ngokulandelana kwemiphumela yokuhlolwa 1, 2, 3, kanye nemiphumela evamile 1, 2, 3.

Cindezela okuthi "Buyela" ukuze uphume kusixhumi esibonakalayo futhi ukulinganisa kuqedile.

Qaphela: Ungashintshi idatha ekulinganisweni kokumelana nokushisa kalula ngezikhathi ezijwayelekile. Kungcono ukugcina ikhophi kwezinye izindawo ukuze ugweme ukulahlekelwa idatha yokulinganisa.

Umsebenzisi angaphinda akhethe izinga elilodwa kuphela noma amabili okujiya ukuze alinganise, futhi afake okuthi “0” kokunye.Qaphela:Kusixhumi esibonakalayo sokuthi “Ukulinganisa Ukumelana Nokushisa”, faka idatha yesampula yesipontshi esilinganisiwe ukusuka kwencane ukuya enkulu ngokulandelana kwemiphumela yokuhlolwa 1, 2, 3, kanye nemiphumela evamile 1, 2, 3.

Cindezela okuthi “Buyela” ukuze uphume kusixhumi esibonakalayo futhi ukulinganisa sekuphelile.

Qaphela:Ungashintshi idatha ekulinganisweni kokumelana nokushisa kalula ngezikhathi ezijwayelekile. Kungcono ukugcina ikhophi kwezinye izindawo ukuze ugweme ukulahlekelwa idatha yokulinganisa.

3.3.7 Amasampula asebenzayo okumelana nokushisa

Le nsimbi ayikhawulelwe ekutholeni ukumelana nokushisa kwezindwangu, futhi ingasetshenziswa ekutholeni ukumelana nokushisa kwezinto ezihlukahlukene zamapuleti.

3.4 Qalisa ukusebenza kokumelana nomswakama

3.4.1 Ukushisa kuqala komshini

Ngemuva kokuvula amandla, wonke umshini udinga ukufudumala cishe imizuzu engama-60. Ngaleso sikhathi, kufanele kuqinisekiswe ukuthi umsebenzi woku-3.4.3 wokugcwalisa nokugcwaliswa kabusha kwamanzi kanye nokusebenza kokuhlolwa kokufakwa kwefilimu sekuqediwe. Faka indwangu ewugqinsi omaphakathi epuleti elinezimbotshana, bese ukhipha indwangu lapho ipuleti lokuhlola lifinyelela ku-35℃, Bese uqaphela izinga lokushisa lepuleti lokushisisa kanye nezinga lokushisa lepuleti eliphansi lifinyelele cishe ku-35.2, uqedele ukushisa komshini obandayo, ungabeka isampula yokuhlola ebhentshini lokuhlola.

3.4.2Umswakamaisilungiselelo sokumelana

Cindezela inkinobho ethi “Izilungiselelo”, bese ucindezela u-“Heat and Humidity Resistance Parameter Setting” ukuze ubonise isixhumi esibonakalayo esingu-309.

3.4.3 Umsebenzi wokuswakama nokugcwalisa amanzi

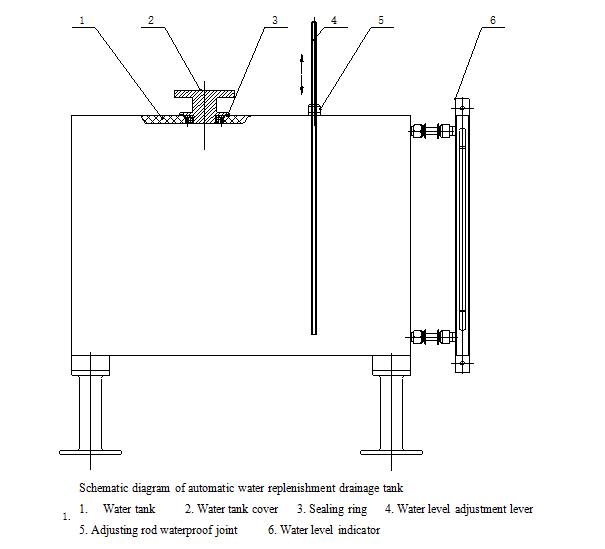

Hlola ukuthi akhona yini amanzi ethangini eligcwalisa amanzi elizenzakalelayo. Uma amanzi engekho, vula umnyango omncane ohlangothini lwesobunxele lwensimbi, ukhulule ikhava yethangi lamanzi 2, bese ufaka induku yenkomba yezinga lamanzi 4 ngaphansi kwethangi lamanzi bese uqinisa intonga yokulungisa engangeni manzi 5, bese uthatha. ifaneli evela kwezesekeli, Bese utheledistilledamanzi emlonyeni wethangi lamanzi, yenza izinga lamanzi phakathi kwemigqa ebomvu yenkomba yezinga lamanzi 6, bese uqinisa isivalo sethangi lamanzi.

Cindezela inkinobho ethi “I-Water Inlet” eboniswe kuMfanekiso 323, khulula kancane isixhumi esingangeni manzi senduku yokulungisa, bese udonsa kancane kancane induku yokulungisa izinga lamanzi. Amanzi ethangini eligcwalisayo azogeleza ngokuzenzakalelayo emzimbeni wokuhlola. Bheka inkomba yezinga lamanzi ngakwesokudla kwebhentshi lokuhlola futhi uhlole Uma uthinta ingaphezulu lepuleti elinezimbotshana ngesandla sakho, lapho umswakama uphuma, ungamisa i-lever yokulungisa izinga lamanzi ukuze idonse, futhi uqinise isixhumi esingangeni manzi. .

Hlola ukubekwa kwefilimu: Thatha ifilimu yokuhlola kokunamathiselwe, udabule ifilimu evikelayo, bese usebenzisa enwebekayo ukuhlola. Yisakaze ebusweni bepuleti elinezimbotshana. Thatha i-cotton block ekunamathiselwe ukuze ubushelelezi ifilimu bese ubushelelezi ifilimu. Susa amabhamuza omoya phakathi kwamapuleti, bese uthatha umugqa werabha kokunamathiselwe, bese ulungisa ifilimu emzimbeni wokuhlola ngendlela eyindilinga.

3.4.4 Ukuhlolwa kwepuleti elingenalutho lokumelana nomswakama

Ngaphambi kokuthi ithuluzi lithole isampula, akumele kube “nokumelana nomswakama okuyisampula”-ukumelana nokumanzi kwebhodi okungenalutho.

Ukumelana nomswakama wepuleti elingenalutho kubhekisela ekumelana nomswakama wensimbi ngokwayo uma kunefilimu kuphela.

Khetha "isikhathi sokurekhoda 0" bese ucindezela u-"Qala" ukuze wenze ukuhlolwa "kwebhodi okungenalutho ukumelana nokuswakama".

Inqubo yokuhlola ukumelana nomswakama: preheat-stable-test-stop (thola ukumelana nomswakama ebhodini elingenalutho futhi ukugcine ngokuzenzakalelayo)

3.4.5 Ukuhlolwa kokumelana nomswakama

Ku-interface yokusebenza kokumelana nomswakama (kungenziwa ngemuva kokuthi izinga lokushisa lamapuleti amathathu lifinyelele isigatshana esingu-3.4.1)

Khetha oku-1 ngesikhathi sokurekhoda (okungukuthi, isampula 1).

Ngemuva kokuthi ithuluzi lihlangabezane nezidingo ze-3.4.1, beka isampula yokuhlola endaweni engaphezulu yefilimu, cindezela inkinobho "phezulu, phansi", bese uvala izinhlangothi ezine ze-crimp yensimbi. Uma i-crimp yensimbi isendaweni evundlile, beka phansi ikhava ye-plexiglass. Vala umnyango wensimbi bese ucindezela inkinobho ethi "Qala". Insimbi izosebenza ngokuzenzakalelayo. Ukulandelana okusebenzayo yilokhu: i-warm-up-stability-test-stop, futhi ibonise ukumelana nomswakama wokuqala nezinye izinkomba.

Shintsha isampula; cindezela u-2 ukuze uthole isikhathi sokurekhoda ukuze uhlole isampula yesibili, indlela iyafana nengenhla, njalonjalo. Umbiko wokuhlola ukumelana nomswakama ungaphrintwa ngemva kokuhlolwa oku-3 ngokwendlela evamile.

3.4.6 Ukubuka nokuphrinta ukumelana nomswakama

Ukumelana nomswakama kudinga ukulinganiswa. Izinyathelo zifana ne-thermal resistance calibratuion.

3.4.7 Amasampula asebenzayo okumelana nomswakama

Le nsimbi ayinqunyelwe ekutholeni ukumelana nomswakama wezindwangu, ifanele futhi ukutholwa kokumelana nomswakama wezinto ezihlukahlukene zamapuleti, kodwa akusho lutho ukuthola ukumelana nomswakama wezinto ezingenasici, ngoba ukubaluleka kokumelana nomswakama akupheli.

3.4.8Ukuguqulwa kokumelana nomswakama kanye nokuhlolwa kokumelana nokushisa

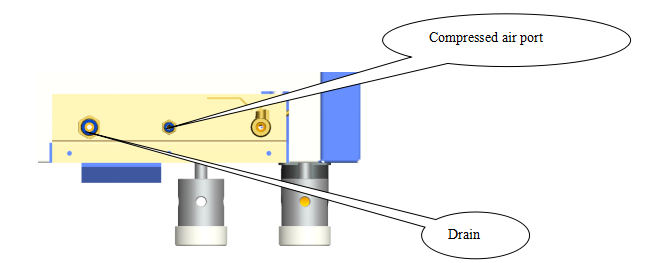

Ohlangothini lwesobunxele lwensimbi, njengoba kukhonjisiwe kuMfanekiso 327, xhuma umoya ocindezelweyo, beka ipani lokudonsa amanzi ngaphansi komsele, bese ucindezela inkinobho ethi “Drain” ngaphakathi kwegumbi lokuhlola njengoba kubonisiwe kuMfanekiso 317, ngokuvamile cindezela okuthi 6 Mayelana no-8. izikhathi (ngesikhathi esisodwa ngemva kokuzwa “ukuchofoza”), amanzi azokhishwa ngokuzenzakalelayo, bese usetha izinga lokushisa ebhodini lokuhlola libe ngu-40 ℃, bese ugijima ihora elingu-1 (ngemuva kwalokho, uma ibhodi lokuhlola kanye nebhodi lokuvikela kusekhona Uma kunomswakama, isikhathi singanwetshwa ngendlela efanele). Lapho wenza lo msebenzi, akufanele kube khona isampula noma ifilimu yokuhlola ukumelana nomswakama endaweni yokuhlola.

lImbobo yomoya ecindezelwe

4.1 Isampula yokulawula ukuswakama: amasampula namasampula okuhlola kufanele abekwe ngaphansi kwezimo ezishiwo zomkhathi ezibekiwe zokulawula umswakama amahora angama-24.

4.2 Ubuningi besampula nosayizi: Thatha amasampula amathathu kusampula ngayinye, usayizi wesampula ngu-35×35cm, futhi isampula kufanele ibe isicaba futhi ingabi nemibimbi.

4.3 Izidingo zokubekwa kwesampula: Uhlangothi olungaphambili lwesampula lubekwe phansi ebhodini lokuhlola, futhi zonke izinhlangothi zebhodi lokuhlola zimboziwe.

lUkubaluleka kokumelana nokushisa nomswakama

5.1Ukumelana nokushisa kuyisici sokusebenza kokudlulisa ukushisa kwezinto. Ingenye yezinkomba eziyisisekelo kakhulu zokuhlola izindwangu. Ngenxa yemisebenzi emithathu eyisisekelo yezingubo (ukugcina imfudumalo, ukuvikela umzimba nokuziveza), into ebaluleke kakhulu ukufudumala. Uma zingekho izingubo namuhla Ukuvikelwa kwesintu akukwazi ukuphila. Okwesibili, izifunda nezinkathi ezahlukene zinezidingo ezihlukene zokushisa. Ukumelana nokushisa kunganikeza isisekelo sokuthi abantu bakhethe ukuthi hlobo luni lwendwangu, okubonisa ukubaluleka kokuthola ukumelana nokushisa.

5.2Ukumelana nomswakama kuyinkomba ekhombisa ikhono lezinto zokudlulisa umswakama. Ngokuthuthukiswa kwezindinganiso zokuphila zabantu, izidingo eziphakeme zibekwe phambili zokugqoka induduzo, ngoba umuntu omdala uzodlula esikhumbeni ngisho noma kungekho umjuluko (umjuluko obalulekile) nsuku zonke I-capillary ikhipha umhwamuko wamanzi (obizwa ngokuthi umjuluko ofihliwe), 30- 70 g/ngosuku*umuntu. Khona-ke iningi lalomswakama lidinga ukudluliselwa ngezingubo. Kuphela lapho ikhono lempahla yokugqoka lokudlulisa umswakama lidlula leli nani lapho abantu bangase bazizwe bekhululekile. Ngenxa yalesi sizathu, kubaluleke kakhulu ukuthola ukumelana nomswakama.

lUkusekela kwezobuchwepheshe

6.1 Ukuhlonza iphutha

A, Asikho isibonisi esikrinini sokuqalisa

- Hlola ukuthi amandla avuliwe yini

- Hlola ukuthi amandla esibonisi axhunyiwe

- Hlola ukuthi amandla esibonisi axhunyiwe

B, Izinga lokushisa elihlala njalo kanye nomswakama awukwazi ukusebenza

- Izinga lamanzi kusixhumi esibonakalayo sebhuthi liphuzi, sicela wengeze amanzi

- Hlola ukuthi umugqa wokuxhuma phakathi kwebhodi lokulawula kanye nebhodi lokushayela uxhumeke kahle

- Hlola ukuthi ingcindezi ye-compressor yesiqandisi iphakeme noma iphansi kunomfutho obekiwe

C, lokushisa njalo kanye nomswakama operation, ongaphakeme test ekamelweni lokushisa

- Hlola ukuthi ishubhu lokushisisa umoya lingashiswa ngokujwayelekile yini;

- Hlola i-state relay eqinile eshayela ishubhu yokushisisa umoya.

D, Ukusebenza kwezinga lokushisa nokuswakama, umswakama ophansi ekamelweni lokuhlola

- Hlola ukuthi ipayipi lokushisisa ithangi lamanzi lingashisisa ngokujwayelekile yini

- Hlola i-relay yesimo esiqinile eshayela ipayipi lokufudumeza ithangi lamanzi

E, Akukho ukubonisa izinga lokushisa ebhodini lokuhlola, ebhodini lokushisisa noma phansi

1. Ukuthi inzwa yezinga lokushisa ishile yini

2. Ukuthintwa kwesixhumi akukuhle, kuxhume futhi.

F, Ibhodi lokuhlola, ibhodi lokushisisa noma ipuleti eliphansi alikwazi ukufudumeza noma lishise kancane

1. Hlola ukuthi amandla kagesi ashintshwayo amathathu ngokuvamile anikezwa amandla;

2. Hlola isifunda sokulawula se-heater ukuze ubone ukuthi kukhona yini ukuthintana okubi nepulaki engaqondile.

6.2 Isondlo

A. Ungangqubuzani nezingxenye ezihlukahlukene ngesikhathi sokuthutha, ukufakwa, ukulungiswa kanye nokusetshenziswa kwethuluzi ukuze ugweme ukulimala komshini futhi uthinte imiphumela yokuhlolwa.

B. Iphaneli yokulawula yensimbi iyikristalu ewuketshezi nesikrini sokuthinta, okuyizingxenye ezilimele kalula. Ungasebenzisi ezinye izinto eziqinile ukushintsha iminwe yakho ngesikhathi sokusebenza. Ungaconsi izincibilikisi eziphilayo esikrinini esithintwayo ukuze ugweme ukufinyeza impilo yesevisi.

C. Yenza umsebenzi omuhle wokwelapha okuvikela uthuli ngemva kokusetshenziswa ngakunye kwethuluzi futhi uhlanze uthuli ngesikhathi.

D. Uma ithuluzi lingasebenzi kahle, sicela ucele uchwepheshe ukuze alungiswe noma alungiswe ngaphansi kokuqondiswa uchwepheshe.

lIzinkinga ezijwayelekile

7.1 Umbuzo wesikhathi sokubona

Isikhathi sokutholwa siyindaba ekhathaza kakhulu wonke umuntu, futhi ngihlale ngithemba ukuthi kuzoshesha futhi kunembile. Njengoba izinga langaphambilini libeka isilinganiso semijikelezo emihlanu yokuvula kanye nesikhathi sokucisha amandla kunoma iyiphi isampuli ngemva kwemizuzu engu-30 yokushisisa kwangaphambili ukuze kubalwe umphumela, cishe kungaphansi kwehora ukuhlola idatha eyodwa. Kunomqondo osuvele ucatshangwe ukuthi ngihlale nginomuzwa wokuthi isikhathi sokuhlola samanje Sesinde kakhulu. Isikhathi sokushisa kwangaphambili esilinganisweni sendlela yamanje sigcizelela isidingo sokufinyelela esimweni esizinzile, kunesikhathi esinqunyiwe sangaphambilini. Lokhu kungenxa yesizathu. Ngenxa yokuthi uhla lokumelana nokushisa kwezindwangu lukhulu, ludinga ukufinyelela ku-35°C kolunye uhlangothi no-20°C ngakolunye uhlangothi. Isikhathi esidingekayo sesimo esizinzile sihlukile. Isibonelo, kuthatha okungenani amahora angu-2 ukuze amajazi afinyelele esimweni esiqinile, kuyilapho amabhantshi aphansi ethatha isikhathi eside. Ngakolunye uhlangothi, izindwangu eziningi zimunca umswakama. Nakuba isampula ilungisiwe futhi yalinganiswa kusengaphambili, isimo sokuhlolwa sishintshile. Izinga lokushisa langaphambili lingu-20 ℃ kanti umswakama ungu-65%, kanti umswakama wangaphambili ungu-35℃ ngakolunye uhlangothi no-20℃ ngakolunye. Ukubuyiswa komswakama wesampula ngemva kokushintsha kwebhalansi nakho. Senze isivivinyo sokuqhathanisa. Isisindo sangaphambili sesampula efanayo sikhulu kunesokuqala. Wonke umuntu uyazi ukuthi kuthatha isikhathi eside ukulinganisa kabusha ukubuyiswa komswakama wezindwangu. Ngakho-ke, isikhathi sokuthola ukumelana nokushisa asikwazi ukuba sifushane.

Kuphinde kuthathe isikhathi eside ukuthi isampula ifinyelele umfutho wamanzi we-isothermal nokungalingani ngesikhathi sokuhlolwa kokumelana nomswakama.

Kuyafana nesikhathi esidingekayo ukuze amathuluzi angaphandle afanayo athole “ukumelana nokushisa nomswakama”, sicela ubheke isithasiselo.

7.2 Umbuzo wosayizi wesampula

Usayizi wesampula uhlale ungcono. Akunjalo ekuhlolweni kokumelana nokushisa. Ilungile kuphela kummeleli wesampula, kodwa isiphetho esiphambene singathathwa entweni. Usayizi webhodi lokuhlola mkhulu futhi ukushisisa Uniformity kuyinkinga. Izinga elisha lidinga isivinini somoya esingu-1m/s. Uma usayizi mkhulu, mkhulu umehluko wejubane phakathi kwendawo yokungena komoya nendawo yokukhipha umoya, kanye nokwanda kwezinga lokushisa lendawo yokungena komoya kanye nezinga lokushisa lendawo yokukhipha umoya. Kusukela ekuthuthukisweni kwamazinga ekhaya naphesheya, siyabona ukuthi izinga elidala liyi-250mm2 futhi izinga elisha lingu-200mm2. I-KES yaseJapan isebenzisa i-100mm2. Ngakho-ke, sikholwa ukuthi u-200 mm2 ufaneleka kakhulu endaweni esebenzayo ngaphansi kwesisekelo sokuhlangabezana namazinga endlela.

7.3 Ukuthi izinga lokushisa lokusetha lihlobene yini nevelu yokumelana nokushisa

Ngokuvamile, izinga lokushisa lokusetha alihlobene nenani lokumelana nokushisa.

Inani lokumelana nokushisa lihlobene nendawo yesampula, umehluko wezinga lokushisa phakathi kwezinhlangothi ezimbili, namandla adingekayo ukuze kugcinwe isimo sokuzinza.

Rct

Uma indawo yebhodi lokuhlola inqunywa, ubukhulu bayo akufanele bushintshe. Uma nje izinga lokushisa emikhawulweni yomibili lingaguquki, akunzima ukukala amandla adingekayo ukuze kugcinwe izinga elifanayo. Kungabonakala ukuthi izinga lokushisa elisetshenzisiwe alinamsebenzi, inqobo nje uma izinga lokushisa elisetshenzisiwe lingaguquki izici zento elinganisiwe. kungaba. Yebo siyalihlonipha izinga futhi sithatha i-35℃.

7.4 Inkinga yenkomba etholiwe

Kungani izinga elisha liqeda izinga lokulondoloza ukushisa futhi lisebenzise inkomba yokumelana nokushisa? Singazi ngefomula yasekuqaleni yezinga lokulondoloza ukushisa:

Q1(Ayikho isampula yokukhishwa kokushisa (W/℃)

Q2-ngesampula yokushabalalisa ukushisa (W/℃)

Ngokuthuthukiswa kokusebenza kwe-thermal, i-Q2 yehla ngokulandelana, kodwa izinga lokufakwa kwe-thermal Q likhuphuka kancane kakhulu. Ekusetshenzisweni kwangempela, izinga lokufakwa okushisayo kwejazi elinezingqimba ezimbili kanye nejazi elilodwa lendlalelo likhuphuka kancane kuphela, aliphindwe kabili. Lona umklamo wefomula Ngakho-ke, kunengqondo ukuqeda le nkomba emazweni ngamazwe. Okwesibili, ukumelana nokushisa kulula kakhulu ukusebenzisa, futhi inani lengezwe ngokulinganayo. Ngokwesibonelo, ijazi lokuqala lingu-0.085 m2·K/W, kanti esitezi sesibili singu-0.170 m2·K/W.

Ubudlelwano phakathi kokumelana ne-thermal kanye nesilinganiso sokufakelwa:

Rct=A/Q2-Rct0 A:indawo yokuhlola

Ngokusho kwefomula, ukumelana nokushisa kuyashintsha ngokuvumelana nokushintsha kwe-Q2.

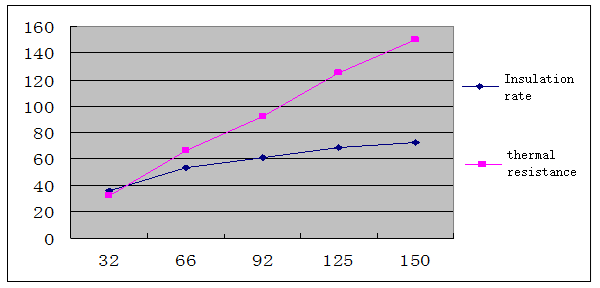

Izibonelo ezilandelayo zedatha yokuhlola ukumelana nokushisa:

| Izikhathi zokuhlola | 1 | 2 | 3 | 4 | 5 | I-thermal engenalutho |

| Idatha yokumelana nokushisa (10-3m2·K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

A ngu-0.04m2futhi i-Q2 izoba:

| Izikhathi zokuhlola | 1 | 2 | 3 | 4 | 5 | Idatha yokumelana nokushisa |

| Idatha yokumelana nokushisa 10-3m2·K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

| Q2 (W/℃) | 0.4444 | 0.3226 | 0.2667 | 0.2186 | 0.1923 |

|

Q1 Ayikho isampula yokukhishwa kokushisa, Q1=A/Rct0=0.04/58*1000=0.6897

| Izikhathi zokuhlola | 1 | 2 | 3 | 4 | 5 | Idatha yokumelana nokushisa |

| Ukumelana nokushisa (10-3m2·K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

| Q2 (W/℃) | 0.4444 | 0.3226 | 0.2667 | 0.2186 | 0.1923 |

|

| Izinga le-insulation (%) | 35.57 | 53.22 | 61.33 | 68.31 | 72.12 |

|

Ngokusho kwedatha, umdwebo wejika wokumelana nokushisa kanye nesilinganiso sokufaka:

t kungabonakala kulokhu ukuthi njengoba ukumelana nokushisa kuba kukhudlwana, izinga lokugcinwa kokufudumala livame ukuba flat, okungukuthi, lapho ukumelana nokushisa kukhulu, izinga lokugcinwa kokufudumala kunzima ukukhombisa ukuthi likhulu ngempela.

7.5 Ukulinganiswa kwethuluzi kanye nezinkinga zesampula ezijwayelekile

Ukuqinisekiswa kwezinsimbi zokumelana nokushisa nomswakama sekuyinkinga enkulu. Uma izinga lokushisa lepuleti eliphansi lizolinganiswa, alikwazi ukutholwa ngoba ithuluzi livaliwe. Kunezici eziningi kakhulu ezithinta imiphumela yokuhlolwa. Izindlela zokuqinisekisa zangaphambilini ziyinkimbinkimbi futhi azikayixazululi inkinga. Kwaziwa kahle ukuthi ukuguquguquka kwemiphumela yokuhlolwa kwethuluzi lokufaka ukushisa okushisayo kuyiqiniso elingephikiswe. Ngokusho kokuhlola kwethu kwesikhathi eside, sikholelwa ukuthi "isampula evamile" isetshenziselwa ukuqinisekisa "imitha yokumelana nokushisa" "Kulula futhi kungokwesayensi.

Kunezinhlobo ezimbili zamasampuli ajwayelekile. Enye iwukusebenzisa izindwangu (i-chemical fiber plain weave), kanti enye isipontshi.

Nakuba izindwangu zingacaciswanga kumazinga asekhaya nakwamanye amazwe, indlela ye-superposition enezingqimba eziningi isetshenziswa ngokucacile ukulinganisa ithuluzi.

Ngemuva kocwaningo lwethu, sikholelwa ukuthi akunangqondo ukusebenzisa indlela ye-superposition, ikakhulukazi i-textile superimposition. Wonke umuntu uyazi ukuthi ngemuva kokuthi i-textile ibekwe phezulu, kukhona izikhala phakathi, futhi kusekhona umoya esikhaleni. Ukumelana okushisayo komoya omile kungaphezu kokuphindwe kabili ukumelana nokushisa kwanoma iyiphi indwangu. Ubukhulu begebe bukhulu kunobukhulu bendwangu, okusho ukuthi ukumelana nokushisa okukhiqizwa igebe akuncane. Ngaphandle kwalokho, igebe lokugqagqana lihlukile esivivinyweni ngasinye, okunzima ukusilungisa, okuholela ekunqwabelenini okungaqondile kwamasampula ajwayelekile.

Isipontshi asinazo izinkinga ezingenhla. Amasampula ajwayelekile anokumelana nokushisa okuhlukile abalulekile, awagxiliwe, njenge-5mm, 10mm, 20mm, njll. Yiqiniso, izinto ezisetshenzisiwe zinqunywe zizonke, ezingabhekwa njenge-homogeneous (manje isiponji sifana nobulili Ubulili okuhle) Ukuchaza ukuthi amabhamuza esipontshini afanayo, lokhu okungenhla kubhekise egebeni elengeziwe phakathi kwezingqimba.

Ngemuva kokuhlolwa okuningi, isipontshi siyinto elula kakhulu futhi ewusizo. Kunconywa ukuthi iyunithi yokugxila ejwayelekile iyisebenzise.

Isithasiselo

Isikhathi sesithenjwa sokuhlola

| Ukuhlukahluka kwesampula | Isikhathi sokumelana nokushisa (imizuzu) | Isikhathi sokumelana nomswakama (amaminithi) |

| Indwangu ezacile | Cishe ama-40 ~ 50 | Cishe ama-50 ~ 60 |

| Indwangu emaphakathi | Cishe ama-50 ~ 60 | Cishe 60~80 |

| Indwangu ewugqinsi | Cishe 60~80 | Cishe 80-110 |

Qaphela: Isikhathi sokuhlola esingenhla cishe silingana nezinsimbi ezifanayo emhlabeni

I-SHANDONG DRICK ISTRUMENTS CO., LTD

Iphrofayela Yenkampani

I-Shandong Drick Instruments Co., Ltd, ibambe iqhaza kakhulu ocwaningweni nasekuthuthukisweni, ekukhiqizeni nasekuthengisweni kwezinsimbi zokuhlola.

Inkampani yasungulwa ngo-2004.

Imikhiqizo isetshenziswa kumayunithi ocwaningo lwesayensi, izikhungo zokuhlola ikhwalithi, amanyuvesi, ukupakisha, iphepha, ukuphrinta, irabha namapulasitiki, amakhemikhali, ukudla, imithi, izindwangu, nezinye izimboni.

U-Drick unaka ukukhuliswa kwethalente nokwakhiwa kweqembu, ukubambelela emcabangweni wokuthuthukiswa kobuchwepheshe, ukuzinikela.pragmatism, kanye nokusungula izinto ezintsha.

Ukunamathela esimisweni esigxile kumakhasimende, ukuxazulula izidingo eziphuthumayo nezisebenzayo zamakhasimende, futhi unikeze izixazululo ezisezingeni lokuqala kumakhasimende anemikhiqizo yekhwalithi ephezulu kanye nobuchwepheshe obuphambili.