Hydraulic Universal Testing Machine WAW-600D Microcomputer Inodzorwa

Tsanangudzo Pfupi

WAW-600D Microcomputer Inodzorwa Hydraulic Universal Testing Machine Chigadzirwa Overview: Muviri mukuru weWAW-600D microcomputer inodzorwa electro-hydraulic servo hydraulic universal test muchina inotora silinda pasi mhando huru chimiro chemuviri, inonyanya kushandiswa kumichina bvunzo dzekuita senge kushushikana, kudzvanya. , kukotama kwezvinhu zvesimbi, zvisiri zvesimbi, zvikamu zvechigadzirwa, zvikamu, zvimiro zvemukati, uye mwero zvikamu. Kana yakashongedzerwa nemidziyo yezvakatipoteredza, iyi serie ...

WAW-600D Microcomputer InodzorwaHydraulic Universal Testing Machine

Product Overview:

Muviri mukuru weWAW-600D microcomputer inodzorwa electro-hydraulic servo hydraulic universal yekuyedza muchina inotora silinda pasi mhando huru chimiro chemuviri, inonyanya kushandiswa kumichina bvunzo dzekuita sekunetsa, kudzvanya, kukotama kwesimbi zvinhu, zvisiri zvesimbi, chigadzirwa. zvikamu, zvikamu, zviumbwa zvezvikamu, uye zvikamu zvakajairika.

Kana yakashongedzerwa nemidziyo yezvakatipoteredza, iyi nhevedzano yemichina yekuyedza inogona zvakare kuita zvinhu zvinorema, kumanikidza, uye kupeta bvunzo munzvimbo iyoyo. Semuyenzaniso: tembiricha tembiricha, yakaderera tembiricha tembiricha, compression uye mamwe bvunzo.

Inokodzera simbi, simbi, zvokuvakisa, unhu kuongorora nzvimbo, mvura kuchengetedza uye hydropower, migwagwa mikuru mabhiriji, tsvakurudzo masangano, michina engineering mumakoreji nemayunivhesiti, uye mamwe mafekitari, migodhi, mabhizinesi, uye bvunzo uye tsvakurudzo masangano.

Kugadzira uye kuongorora zviyero zvezvigadzirwa

GB2611 "General Tekinoroji Zvinodikanwa zvekuyedza Machina"

JJG139 "Tensile, Pressure, uyeUniversal Testing Machine“

Inoshanda bvunzo nzira zviyero

Kuedza kushanda uye kugadzirisa data kunosangana nezvinodiwa zvemazana ezviyero zvakaita seGB/T228 “Tensile Test Method yeMetallic Materials at Room Temperature”, GB/T7314 “Compression Test Method for Metallic Materials at Room Temperature”, GB/T232 “Bending Test Method yeMetallic Materials ", nezvimwewo Uye nzira dzekugadzirisa data dzinosangana nemhando dzakasiyana dzinogona kugadzirwa zvinoenderana ne zvinodiwa nevatengi.

Main michina zviratidzo

1 Mugamuchiri

Injini huru inotora yakadzika yakagadzika silinda yemhando, ine nzvimbo inotambanuka iri pamusoro peinjini huru, uye yekumanikidza uye yekukotama nzvimbo yekuyedza iri pakati peyakadzika crossbeam yeinjini huru uye inoshanda.

2 Transmission System

Kusimudzwa kwemuchinjiko wepakati kunotora mota inofambiswa nevhiri reketani kutenderedza screw, kugadzirisa nzvimbo yepakati yepakati nepakati uye kugadzirisa tension uye compression nzvimbo.

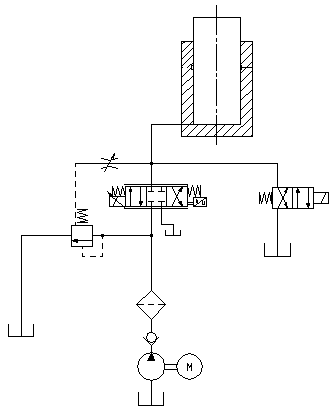

Iyo hydraulic musimboti weiyo hydraulic system inoratidzwa muFigure 2, inova inotakura inogadzirisa mafuta inlet throttling speed control system.

Mufananidzo 2 Hydraulic schematic diagram

Oiri ye hydraulic mutangi yemafuta inofambiswa nemota kuti ipinde munharaunda yeoiri, uye inoyerera nepakati-imwe nzira vharafu, yakakwirira-kudzvanywa mafuta sefa, musiyano wekumanikidza vharafu boka, servo valve, uye inopinda muiri cylinder. Iyo komputa inotumira masaini ekudzora kune yakaenzana servo valve kudzora kuvhurwa uye kutungamira kweyakaenzana servo vharafu, nekudaro ichidzora kuyerera muhumburu yeoiri uye kuwana kudzora kweanogara achimhanya bvunzo simba, inogara ichimhanya kufambisa, nezvimwe.

4. Kuyera kwemagetsi uye kudzora system:

(1) Izvo zvakakosha zveiyo servo control oiri sosi ese ari kunze kwenyika ekutanga zvinhu zvine kuita kwakagadzikana.

(2) Iine mabasa ekudzivirira akadai sekuremedza, overcurrent, overvoltage, displacement kumusoro uye yakaderera miganho, uye emergency stop.

(3) Iyo yakavakirwa-mukati controller yakavakirwa paPCI tekinoroji inova nechokwadi chekuti muchina wekuyedza unogona kuwana yakavharwa-loop kutonga kwema paramita senge test force, specimen deformation, uye danda kutamiswa, uye inogona kuita bvunzo dzakadai sekugara velocity bvunzo simba, inogara ichimhanya. kutama, kuenderera mberi kwevelocity strain, kutenderera kwevelocity load cycle, uye nguva dzose velocity deformation cycle. Smooth switching pakati peakasiyana ekudzora modes inogoneka.

(4) Pakupera kwekuedza, inogona kudzoserwa nemaoko kana otomatiki kunzvimbo yekutanga yekuyedza nekukurumidza.

(5) Yakawana zeroing yechokwadi yemuviri, kuwana kugadziridzwa, uye otomatiki kuchinjika, zeroing, calibration, uye kuponesa kwekuyedza simba kuyerwa, pasina chero analogi inogadzirisa zvinongedzo, uye dunhu rekutonga rakanyatsobatanidzwa.

(6) Dunhu remagetsi rekudzora rinotevera zviyero zvepasi rose uye rinoenderana nenyika yekuyedza muchina wemagetsi zviyero. Iine simba rakasimba rinopesana nekupindira, kuvimbisa kugadzikana kwemutongi uye nekururama kwe data yekuedza.

(7) Yakashongedzerwa netiweki yekutumira interface, inogona kuita data kuendesa, kuchengetedza, kudhinda marekodhi, uye network transmission printing, uye inogona kubatanidzwa kune yemukati LAN kana Internet network yebhizinesi.

5. Tsanangudzo yezvinhu zvakakosha zvinoshanda zvesoftware

Iyi yekuyera uye yekudzora software inoshandiswa kune microcomputer inodzorwa electro-hydraulic servo hydraulic universal yekuyedza muchina kuita akasiyana simbi uye asiri-simbi bvunzo, yakakwana chaiyo-nguva kuyerwa uye kuratidza, chaiyo-nguva kutonga uye kugadzirisa data, kubuda kwemhedzisiro uye mamwe mabasa zvinoenderana. kumipimo inoenderana.

(1) Mvumo yakavakirwa manejimendi, uko vashandisi pamatanho akasiyana vane mvumo yekushanda yakasiyana uye kuwana mamenu nezvimwe zvirimo. Izvi hazvingorerutsa, kufambisa, uye nekumhanyisa mashandiro evashandisiwo zvavo, asi zvakare zvinodzivirira zvinobudirira sisitimu;

(2) Kuyera nguva chaiyo uye kuratidzwa kwesimba rekuyedza, kukosha kwepamusoro, kutama, deformation uye zvimwe zviratidzo; Nguva chaiyo yekuunganidza uye kutonga kwave kuwanikwa pachikuva; Uye yakawana chaiyo nguva uye yakanyanya-kumhanya sampling;

(3) Chaiyo nguva chidzitiro chiratidziro cheakasiyana bvunzo macurve senge deformation yekuremerwa uye kutakurwa kwemutoro kwave kuwanikwa, iyo inogona kuchinjika nekuonekwa chero nguva. The zooming mukati uye kunze macurves zviri nyore chaizvo;

(4) Komputa ine mabasa akadai sekuchengeta, kuseta, uye kurodha zviyedzo paramita. Zeroing, calibration, uye mamwe mashandiro anoitwa kuburikidza nesoftware, uye imwe neimwe parameter inogona kuchengetwa nyore uye kutumirwa kunze kwenyika, zvichiita kuti zvive nyore kushandura pakati peakawanda sensors pane muenzi pasina chero muganho pahuwandu hwe sensors;

(5) Tsigira nzira dzekudzora dzakawanda, dzinosanganisira yakavhurika-loop inogara ichifambisa kufambisa, inogara ichimhanya simba, inogara ichimhanya kushushikana, uye dzimwe dzakavharika-loop nzira dzekudzora; Uye ipa akajairika mareferenzi macurves panguva yekugadzirisa maitiro eakavharwa-loop paramita nevashandisi vepamberi, kuitira kuti vashandisi vanyatso kuona mabatiro eparameter yega yega pane yakavharwa-loop maitiro.

(6) Yakashongedzerwa neakangwara nyanzvi sisitimu yekuseta maitiro ekudzora maitiro, ichipa vashandisi vehunyanzvi vane otomatiki programmable programmers. Vashandisi vanogona kusanganisa nzira dzakawanda dzekudzora uye kumhanya kwekudzora zvinoenderana nezvinodiwa chaizvo nemitemo, uye kugadzira zvirongwa zvekudzora zvinoenderana nezvavanoda. Iyo yekuyera uye yekudzora software inongozvidzora iyo yekuyedza maitiro zvichienderana nemaseting emushandisi.

(7) Ongorora data kuburikidza nekudyidzana kwevanhu-kombuta. Iyo nzira yekugadzirisa inosangana nezvinodiwa zveyakashandiswa zvakanyanya zviyero uye inogona kungoverengera akasiyana ma paramita ekuita senge elastic modulus, goho simba, uye yakatsanangurwa isina proportional tensile simba. Inogonawo kupindira nemaoko mukugadzirisa maitiro ekuvandudza kururamisa kwekuongorora; Kumwe kugadziridzwa kwedata kunogonawo kuitwa zvinoenderana nemazinga anopihwa nemushandisi.

(8) Iyo data yekuyedza inochengetwa mumafaira emafaira kune zviri nyore mushandisi mibvunzo, uye inogona kufambiswazve uchishandisa chero yakajairwa kutengeserana chirevo kana izwi rekugadzirisa software, ukuwo uchifambisa kufambisa data kuburikidza neinternet;

(9) Iyo data curve yekuyedza maitiro inogona kurekodhwa uye kuchengetwa, uye iyo curve inogona kufukidzwa uye kuenzaniswa kuitira nyore kuenzanisa kuongorora;

(10) Chirevo chebvunzo chinogona kudhindwa muchimiro chinodiwa nemushandisi. Vashandisi vanogona kusarudza zvirimo mushumo inoburitsa ruzivo rwekutanga, mhedzisiro yekuyedza, uye macurves ekuyedza kusangana nezvinodiwa zvakasiyana;

(11) Iyo yedhijitari zeroing uye otomatiki calibration yekuedza simba uye deformation yave kuwanikwa, iyo inofambisa kushanda uye inovandudza kuvimbika kwemuchina. Yakasiyana-siyana paramende masisitimu anochengetwa mufomu refaira kuti ive nyore kuchengetedza uye kudzoreredza;

(12) Inogona kuiswa kune iyo Win7 inoshanda system. Kudzora kwemaitiro ekuyedza, shanduko mukumhanya kweiyo crossbeam kufamba, parameter kupinza, uye mamwe ma operation anogona kupedzwa uchishandisa kiibhodhi kana mbeva, zvichiita kuti zvive nyore uye nekukurumidza kushandisa;

(13) Yakashongedzerwa nekudzivirira kwekuremerwa uye otomatiki yekuvhara basa, inogona kuona otomatiki kutsemuka kwemuenzaniso uye kudzima otomatiki.

Zvinoenderana neakasiyana evashandisi zvinodiwa, ari pamusoro software mabasa anogona kugadziriswa kana kugadziridzwa.

6. Software uye software yekushandisa interface:

(1) Iyo software inogona kumhanya paWindows 7 system, uye iyo mushandisi interface inopa yeChinese hwindo system inoenderana neWindows maitiro. Ese maitirwo ekuedza anogona kupedzwa kuburikidza nekuisa mbeva pakombiyuta skrini.

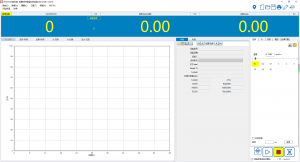

Main interface yemuchina wekuyedza

(Iyo software interface yakasiyana zvishoma, kunyanya yakavakirwa pachokwadi)

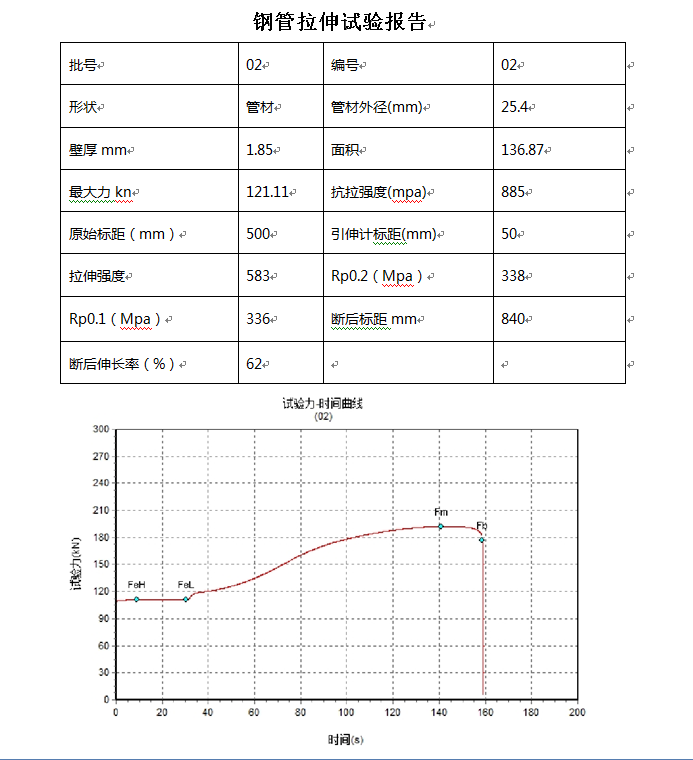

7. Test report:

Tsvaga uye maneja data rekuyedza kuburikidza nemafaira e data; Gadzirisa zvirimo uye fomati yezviyedzo mishumo kuburikidza nemishumo template marongero; Nekugadzirisa mafomula uye zvinhu zvinoguma, rutsigiro rwehuwandu hwakawanda hweyedzo zviyero uye nzira dzinogona kuwanikwa; Mushure mekurodha imwe kana akawanda bvunzo data faira, gadzira bvunzo mushumo zvinoenderana neyemushumo template uye woidhinda kunze; Inotsigira Shoko uye Excel report matemplate, uye anogona kugadziridzwa zvakasununguka;

(Iyo data ndeyekutarisa chete uye haina kukosha kwayo)

8. Chigadzirwa chekudzivirira chekuchengetedza

(1) Kana simba rekuedza richipfuura 2% -5% yehukuru hwekuedza simba, kudzivirira kwekuremerwa kunoitwa uye sisitimu inodururwa.

(2) Kana piston yakwira kusvika padanho repamusoro, kudzivirira sitiroko kunomira uye pombi yemafuta inomira.

Main performance uye technical zviratidzo

| AIHWA. | Project Name | Parameters |

| 1 | Maximum test force kN | mazana matanhatu |

| 2 | Host chimiro | Mbiru ina nemakona maviri ekutungamirira |

| 3 | Chikanganiso chinokanganisa chechiratidzo chesimba rekuedza | ≤ ± 1% yemutengo wakaratidzwa |

| 4 | Chiyero chekuyera simba renji | 2% ~ 100% yehukuru hwekuyedza simba |

| 5 | Constant velocity stress control range (N/mm2 · S-1) | 2~60 |

| 6 | Constant strain control range | 0.00025/s~0.0025/s |

| 7 | Constant velocity displacement control range (mm/min) | 0.5~50 |

| 8 | clamping system | Hydraulic clamping |

| 9 | Circular specimen clamping diameter range mm | Sarudza chero seti mukati mechikamu che Φ 6 kusvika Φ 40 |

| 10 | Flat specimen clamping ukobvu range mm | 0~15 |

| 11 | Flat specimen clamping wide mm | makumi manomwe |

| 12 | Maximum tensile test space mm | 550 (saizi customizable) |

| 13 | Maximum compression test space mm | 500 (saizi customizable) |

| 14 | Kudzora kabati ekunze zviyero mm | 1100×620×850 |

| 15 | Zviyero zvekugamuchira mumamirimita | 900 × 630 × 2300 (saizi inogona customized) |

| 16 | Motokari simba kW | pfungwa mbiri nhatu |

| 17 | Host uremu kg | chiuru nemazana mashanu |

| 18 | Chinhambwe chepakati chechikamu (mm) | mazana mana namakumi mashanu |

| 19 | Yepamusoro uye yakaderera pressure plate size mm | Φ160 |

| 20 | Kupeta tsigiro tsvimbo yepakati mm | 450 (saizi customizable) |

| 21 | Kupeta tsvimbo yekutsigira hupamhi mm | 140 (saizi customizable) |

| 22 | Inobvumirwa beng degree mm | 100 (saizi customizable) |

| 23 | Maximum piston sitiroko mm | mazana maviri |

| 24 | Maximum piston kufamba kumhanya mm/min | Vanenge makumi matanhatu |

| 25 | Kuedza nzvimbo kugadzirisa kumhanya mm/min | Vanenge 150 |

Standard configuration

| AIHWA. | Zita | Zvinotsanangurwa | Qty. | mashoko |

| 1 | host |

| 1 Set | Kuzvigadzira |

| 2 | Servo inodzorwa mafuta sosi |

| 1 Set | Kuzvigadzira |

| 4 | Kudzora kabati |

| 1 Set | Kuzvigadzira |

| 5 | Kuyera uye Kudzora System |

| 1 Set | Kuzvigadzira |

| 6 | Wheel inotaura sensor |

| 1pcs | Wide test |

| 7 | Kutambanudza encoder |

| 1pcs | Jinan |

| 8 | kombiyuta |

| 1 Set | HP |

| 9 | printer |

| 1 Set | HP |

| 10 | Round specimen shaya mm | Sarudza chero peya mukati mechikamu che Φ 6- Φ 13, Φ 13- Φ 26, uye Φ 26- Φ 40. | 1pcs | Kuzvigadzira

|

| 11 | Sample shaya shaya mm | 0~15 | 1pcs | |

| 12 | Compression attachment mm | Φ150 | 1 Set | Kuzvigadzira |

| 13 | Pombi yemafuta |

| 1 Set | Mazzic, Italy |

| 14 | michina yemagetsi |

| 1 Set | Shanghai Songhui |

| 15 | Zvinyorwa zveunyanzvi | Chinyorwa chemushandisi, runyorwa rwekurongedza, chitupa chekuenderana | 1pcs | Kuzvigadzira |

Maitiro ekushanda:

Maitiro ekushanda e electro-hydraulic servo yekuongorora muchina

1. Tanga komputa uye pinda software

2. Tanga kushandura simba uye mafuta sosi main switch ye electro-hydraulic servo controller

3. Rongedza iyo yepakati crossbeam yemuchina wekuyedza muchina panzvimbo yakakodzera, uye tsiva iyo yakakodzera gadziriso zvinoenderana nechimiro, saizi, uye chinangwa chekuyedza chemuenzaniso.

4. Batidza magetsi epombi yemafuta uye simudza silinda yemafuta yemushini wekuyedza kuti ubvise uremu hwayo. (Unogona kusarudza kumhanya kwe10mm/min wobva wadzvanya bhatani re[Kumusoro] kusimudza silinda yemafuta neinosvika 1mm).

5. Isa ruzivo rwakakosha pamusoro pemaitiro mune data version ye software.

6. Mushure mekurovera sitaira pashaya yepamusoro, gadzirisa kukosha kwesimba kuenda ku zero, gadzirisa bhanhire repakati kuenda panzvimbo yakakodzera, sunga shaya yepasi, uye gadzirisa patsva uye deformation. (Iyo maitiro anofanirwa kusungirirwa kune inodarika 80% yeshaya dzese, uye ichengetedzwe yakatwasuka uye yakabatana)

7. Sarudza kumhanya kwakakodzera kana kuronga, tinya bhatani 【Tanga】 musoftware, uye ita kuyedza.

Mushure mekuputsika kwemuenzaniso, bvunzo inopera. Kuti utarise data rekuyedza, tinya pane iyo data vhezheni musoftware kuti uone data inodiwa

Mushure mekupedzwa kweese bvunzo bvunzo, iyo silinda piston yemafuta inowira pasi pehumburumbira yeoiri uye oiri sosi main switch inodzimwa.

8. Buda purogiramu yekushanda, vhara kombiyuta, uye bvisa simba rekugamuchira.

Chenjerera:

1. Shavings yesimbi mushaya dzemuchina wekuedza inofanira kubviswa nguva dzose kuchengetedza shaya dzakachena

Paunenge uchichenesa midziyo nekuchengetedza hutsanana munzvimbo yekushanda, simba rinofanira kubviswa

Munguva yekuyedza, kana pombi yemafuta ikangoerekana yamira kushanda, mutoro wakaiswa unofanirwa kuburitswa, kutariswa, uye pombi yemafuta inofanira kutangwazve.

Kana muchina wekuyedza ukamiswa kwenguva, mota yepombi yemafuta inofanirwa kudzimwa, uye bhenji rekuyedza rinofanira kudzikiswa mushure mekunge bvunzo yapera. Iyo piston yecylinder yemafuta haifanire kuwira pasi pesilinda uye kuyerera kunze kweimwe chinhambwe kufambisa kushandiswa mune ramangwana.

5. Rega kurega mudziyo uchinyorova kana kusangana nezvinhu zvinoyerera, uye kudzivirira kuti mudziyo usazununguke kana kukanganiswa.

6. Ndapota usabva muimba yekushanda uye shandisa shanduko yekumira kwechimbichimbi kana pane dambudziko

7. Gara kure nekukanganiswa kwemagineti

8. Vasina hunyanzvi hwevashandi vehunyanzvi havabvumidzwe kushandura chirongwa chesoftware yemuchina wekuyedza

Hunhu Hwakanaka

Iyo kambani inovimbisa kuti zvigadzirwa zvese zvinogadzirwa zvinoenderana neanoenderana nyika zviyero;

Iyo kambani inovimbisa kuti zvese zvemukati zvishongedzo zvinobva kune zvinozivikanwa mabhureki ane yakanakisa mhando;

Iyo kambani inovimbisa kuti zvese zvekunze zvishongedzo ndezvekutanga uye zvechokwadi zvigadzirwa kubva kufekitori;

Iyo kambani inovimbisa kuti zvigadzirwa zvinopihwa kune vashandisi michina mitsva yepakutanga;

Iyo kambani inovimbisa kuti zvese zvigadzirwa zvinobuda mufekitori zvinoongororwa zvakasimba maererano nemaitiro;

Kambani inovimbisa kugamuchira vatengi kuti vashanyire uye vatarise fekitori chero nguva.

Mamiriro ekugadzirira kwemushandisi

Vashandi vane hunyanzvi mumashandisirwo emakombuta;

Mushandisi anofanirwa kujekesa nzira dzekuyedza uye neyakajairwa ruzivo irwo kuyedza kunoreva uye kunotevera;

Ipa samples dzakaedzwa pamuchina uyu wekuyedza chigadzirwa, kuongorora fekitori, uye kuyedza kugadzirisa muchina;

Iyo nzvimbo, hwaro, magetsi, nezvimwe zvinodikanwa pakuiswa kwechigadzirwa;

Murabhoritari inofanira kunge ine air conditioning, ine tembiricha yemukati inodzorwa pakati pe15-25 ℃ uye humidity <70%;

Inotarisira kugamuchira, kuchengetedza, uye kutamisa zvigadzirwa;

Kushandisa uye kugadzirisa

Vakagadziriswa uye vakadzidziswa bvunzo vashandi vanofanirwa kurongeka kuti vashandise chigadzirwa, uye vamwe havabvumidzwe kuchishandisa;

Paunenge uchishandisa chigadzirwa, vashandisi vanofanirwa kutevedzera kudzidziswa uye nhungamiro yavakagamuchira kuti vashande nenzira kwayo;

Vashandi vanofanirwa kuve nehunyanzvi mune inoenderana bvunzo zviyero kuti vaone nemazvo mhinduro dzebvunzo;

Vashandi vanofanira kunyatsoverenga bhuku rekugadzirira uye software manual;

Pakupera kwekuyedza, dzima muchina muhurongwa hwakakodzera uye cheka masimba ese emagetsi;

Kana yakazviitira bvunzo yekubatsira zvigadziriso ikashandiswa, iyo yekutanga chimiro chechigadzirwa haifanirwe kuchinjwa kana kukuvadzwa panguva yekuiswa;

Kana paine mamiriro asina kujairika kana kutadza kwemagetsi panguva yekushanda kwemuchina wekuyedza, uye bhatani rekutanga kana rekumisa harishande, simba rinofanira kubviswa pakarepo kuti rimise muchina wekuyedza kuti ushande;

Iyo screw uye zvikamu zvekutapurirana zvinofanirwa kugara zvakaputirwa nemafuta ekuzora kudzivirira kukakavara kwakaoma;

Kana chigadzirwa chikasashanda zvakanaka, ndapota taura nedhipatimendi redu rebasa revatengi panguva uye usazviparadzanise zvakananga pasina mvumo;

Usagadzirise chigadzirwa iwe pachako.

Iyo kambani SHANDONG DRICK ISTRUMENTS CO., LTD

Profile yekambani

Shandong Drick Instruments Co., Ltd, inonyanya kuita tsvagiridzo nekusimudzira, kugadzira uye kutengesa kwezviridzwa zvekuyedza.

Iyo kambani yakavambwa muna 2004.

Zvigadzirwa zvinoshandiswa mune zvesainzi zvekutsvagisa zvikamu, zvemhando yekuongorora masangano, mayunivhesiti, kurongedza, mapepa, kudhinda, rabha nemapurasitiki, makemikari, chikafu, mishonga, machira, uye mamwe maindasitiri.

Drick anotarisisa kurima tarenda uye kuvaka kwechikwata, kuomerera kune yekuvandudza pfungwa yehunyanzvi, kuzvipira.pragmatism, uye hunyanzvi.

Kuomerera kumusimboti unotungamirwa nevatengi, gadzirisa zvinonyanya kukurumidza uye zvinoshanda zvinodiwa nevatengi, uye nekupa yekutanga-kirasi mhinduro kune vatengi vane zvigadzirwa zvemhando yepamusoro uye tekinoroji yepamusoro.