Hydraulic Universal Testing Tshuab WAW-600D Microcomputer Tswjhwm

Lus piav qhia luv luv:

WAW-600D Microcomputer Controlled Hydraulic Universal Testing Tshuab Khoom Txheej txheem cej luam: Lub cev tseem ceeb ntawm WAW-600D microcomputer tswj electro-hydraulic servo hydraulic universal kuaj tshuab txais lub tog raj kheej down hom lub cev lub cev, feem ntau yog siv rau kev ntsuas kev ua haujlwm xws li nro, compression. , dabtsi yog khoov ntawm cov ntaub ntawv hlau, cov ntaub ntawv tsis yog hlau, cov khoom siv, cov khoom, cov khoom siv, thiab cov qauv ntu. Yog tias nruab nrog cov khoom siv ib puag ncig, qhov no series ...

WAW-600D Microcomputer ControlledHydraulic Universal Test tshuab

Product Overview:

Lub cev tseem ceeb ntawm WAW-600D microcomputer tswj electro-hydraulic servo hydraulic universal kuaj tshuab txais lub tog raj kheej down hom lub cev lub cev, feem ntau yog siv rau kev ntsuas kev ua tau zoo xws li nro, compression, khoov ntawm cov ntaub ntawv hlau, cov khoom tsis yog hlau, khoom cov khoom, cov khoom siv, cov khoom siv hluav taws xob, thiab cov qauv txheem.

Yog tias nruab nrog cov khoom siv ib puag ncig, cov tshuab ntsuas cov tshuab no tuaj yeem ua cov khoom tensile, compression, thiab dabtsi yog khoov kuaj hauv qhov chaw ntawd. Piv txwv li: kub tensile, tsis kub tensile, compression thiab lwm yam kev ntsuam xyuas.

Haum rau cov hlau, metallurgy, cov khoom siv hauv tsev, cov chaw soj ntsuam zoo, kev txuag dej thiab kev siv dej, kev loj choj, cov koom haum tshawb fawb, mechanical engineering hauv cov tsev kawm qib siab thiab cov tsev kawm qib siab, thiab lwm cov chaw tsim khoom, mines, kev lag luam, thiab cov chaw sim thiab tshawb fawb.

Kev tsim khoom thiab tshuaj xyuas cov qauv rau cov khoom

GB2611 "Cov Lus Qhia Tshwj Xeeb rau Kev Ntsuas Cov Tshuab"

JJG139 "Tensile, Siab, thiabUniversal Test Machine“

Cov qauv kev xeem uas siv tau

Kev sim ua haujlwm thiab ua cov ntaub ntawv ua tau raws li qhov xav tau ntawm ntau pua tus qauv xws li GB / T228 "Tensile Test Method for Metallic Materials at Room Temperature", GB / T7314 "Compression Test Method for Metallic Materials at Room Temperature", GB / T232 "Bending Test Method for Metallic Materials ", thiab lwm yam. Thiab cov ntaub ntawv ua cov txheej txheem uas ua tau raws li cov qauv sib txawv tuaj yeem teeb tsa raws li cov neeg siv khoom xav tau.

Main technical indicators, As

1 Tus tswv

Lub cav tseem ceeb siv lub hauv qab mounted roj lub tog raj kheej hom, nrog rau qhov chaw stretching nyob rau saum lub ntsiab cav, thiab compression thiab dabtsi yog khoov xeem qhov chaw nyob nruab nrab ntawm lub crossbeam ntawm lub ntsiab cav thiab lub worktable.

2 Transmission System

Lub lifting ntawm nruab nrab crossbeam txais ib lub cev muaj zog tsav los ntawm ib tug saw log tig lub ntsia hlau, kho lub spatial txoj hauj lwm ntawm nruab nrab crossbeam thiab ua tau raws li qhov kev hloov ntawm nro thiab compression qhov chaw.

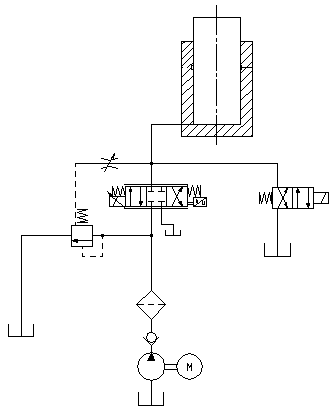

Lub hauv paus ntsiab lus ntawm hydraulic system yog qhia nyob rau hauv daim duab 2, uas yog ib tug load adaptive roj inlet throttling ceev tswj system.

Daim duab 2 Hydraulic schematic daim duab

Cov roj hydraulic nyob rau hauv cov roj tank yog tsav los ntawm lub cev muaj zog kom nkag mus rau hauv cov roj hluav taws xob, thiab ntws los ntawm ib txoj kev valve, siab-siab roj lim, sib txawv siab valve pawg, servo valve, thiab nkag mus rau hauv lub tog raj kheej roj. Lub khoos phis tawj xa cov teeb liab tswj mus rau qhov sib npaug ntawm servo valve los tswj qhov qhib thiab kev taw qhia ntawm proportional servo valve, yog li tswj cov dej ntws mus rau hauv lub tog raj kheej roj thiab ua tiav kev tswj ntawm qhov ntsuas qhov nrawm nrawm, qhov hloov pauv ceev tsis tu ncua, thiab lwm yam.

4. Kev ntsuas hluav taws xob thiab tswj qhov system:

(1) Cov khoom tseem ceeb ntawm servo tswj cov roj qhov chaw yog tag nrho cov khoom tseem ceeb tuaj nrog kev ua haujlwm ruaj khov.

(2) Nws muaj kev tiv thaiv kev ua haujlwm xws li overload, overcurrent, overvoltage, tshem tawm sab saud thiab qis qis, thiab nres thaum muaj xwm ceev.

(3) Lub tshuab tsim ua raws li PCI thev naus laus zis ua kom ntseeg tau tias lub tshuab ntsuas tuaj yeem ua tiav cov voj voog kaw ntawm cov kev txwv xws li kev sim quab yuam, cov qauv deformation, thiab beam hloov chaw, thiab tuaj yeem ua cov kev sim xws li qhov ntsuas nrawm nrawm, qhov nrawm nrawm. Kev hloov pauv tsis tu ncua, qhov nrawm nrawm nrawm, qhov nrawm nrawm nrawm nrawm, thiab lub voj voog tsis tu ncua deformation. Smooth hloov ntawm ntau hom kev tswj yog ua tau.

(4) Thaum kawg ntawm qhov kev sim, nws tuaj yeem ua manually lossis txiav rov qab mus rau qhov chaw pib ntawm qhov kev sim ntawm kev kub ceev.

(5) Nws tau ua tiav qhov tseeb ntawm lub cev zeroing, nce kev hloov kho, thiab tsis siv neeg hloov pauv, zeroing, calibration, thiab txuag ntawm kev sim quab yuam ntsuas, tsis muaj qhov sib txuas sib txuas, thiab kev tswj xyuas Circuit Court yog sib xyaw ua ke.

(6) Lub tshuab hluav taws xob tswj hluav taws xob ua raws li cov qauv thoob ntiaj teb thiab ua raws li lub teb chaws kuaj tshuab hluav taws xob cov qauv. Nws muaj peev xwm tiv thaiv kev cuam tshuam, ua kom muaj kev ruaj ntseg ntawm tus maub los thiab qhov tseeb ntawm cov ntaub ntawv sim.

(7) Nruab nrog lub network sib txuas lus, nws tuaj yeem ua cov ntaub ntawv xa mus, khaws cia, luam ntawv cov ntaub ntawv, thiab luam ntawv sib txuas hauv network, thiab tuaj yeem txuas nrog LAN sab hauv lossis Is Taws Nem network ntawm kev lag luam.

5. Kev piav qhia ntawm cov haujlwm tseem ceeb ntawm cov software

Kev ntsuas thiab tswj software no yog siv rau microcomputer tswj electro-hydraulic servo hydraulic universal kuaj tshuab los ua ntau yam hlau thiab tsis-hlau xeem, ua tiav lub sijhawm ntsuas thiab tso saib, tswj lub sijhawm thiab cov ntaub ntawv ua tiav, cov txiaj ntsig thiab lwm yam haujlwm raws li rau cov qauv sib xws.

(1) Kev tso cai raws li kev tswj hwm, qhov twg cov neeg ua haujlwm ntawm qib sib txawv muaj kev tso cai ua haujlwm sib txawv thiab nkag mus rau cov ntawv qhia zaub mov thiab lwm cov ntsiab lus. Qhov no tsis tsuas yog ua kom yooj yim, yooj yim, thiab ua haujlwm nrawm rau cov neeg ua haujlwm zoo tib yam, tab sis kuj tseem tiv thaiv cov kab ke;

(2) Kev ntsuas lub sij hawm tiag tiag thiab tso saib ntawm kev sim quab yuam, tus nqi siab tshaj, kev hloov pauv, deformation thiab lwm yam teeb liab; Kev sau thiab tswj lub sijhawm tiag tiag tau ua tiav ntawm lub platform; Thiab ua tiav lub sijhawm meej thiab kev ua haujlwm siab ceev;

(3) Lub sijhawm tiag tiag lub vijtsam zaub ntawm ntau yam kev ntsuas nkhaus xws li thauj khoom deformation thiab thauj khoom txav tau tiav, uas tuaj yeem hloov pauv thiab pom txhua lub sijhawm. Lub zooming nyob rau hauv thiab tawm ntawm lub nkhaus yog yooj yim heev;

(4) Lub khoos phis tawj muaj lub luag haujlwm xws li khaws cia, teeb tsa, thiab thauj cov kev sim ntsuas. Zeroing, calibration, thiab lwm yam kev ua haujlwm yog ua los ntawm software, thiab txhua qhov ntsuas tau yooj yim khaws cia thiab xa tawm, ua kom yooj yim hloov ntawm ntau lub sensors ntawm tus tswv tsev yam tsis muaj kev txwv ntawm tus naj npawb ntawm cov sensors;

(5) Txhawb nqa ntau txoj hauv kev, suav nrog kev qhib lub voj voog tas li hloov chaw, qhov nrawm nrawm nrawm, tsis tu ncua kev ntxhov siab, thiab lwm txoj hauv kev kaw lub voj voog; Thiab muab cov qauv siv curves thaum lub sij hawm debugging txheej txheem ntawm kaw-voj tsis los ntawm cov neeg ua haujlwm siab heev, kom cov neeg siv tuaj yeem soj ntsuam qhov cuam tshuam ntawm txhua qhov ntsuas ntawm qhov cuam tshuam kaw.

(6) Nruab nrog cov txheej txheem txawj ntse rau kev teeb tsa cov txheej txheem tswj kev sim, muab cov neeg siv kev paub nrog cov programmable tsis siv neeg. Cov neeg siv tuaj yeem hloov kho ntau txoj hauv kev tswj hwm thiab tswj kev nrawm raws li qhov xav tau tiag tiag thiab cov cai, thiab tsim cov kev tswj hwm uas haum rau lawv cov kev xav tau. Kev ntsuas thiab tswj software yuav cia li tswj cov txheej txheem kuaj raws li cov neeg siv kev teeb tsa.

(7) Tshawb xyuas cov ntaub ntawv los ntawm kev sib cuam tshuam ntawm tib neeg-lub computer. Cov txheej txheem ua tau raws li qhov yuav tsum tau ua ntawm cov qauv siv dav thiab tuaj yeem suav ntau yam kev ua tau zoo xws li elastic modulus, lub zog tawm los, thiab teev tsis muaj zog tensile. Nws kuj tseem tuaj yeem cuam tshuam manually hauv cov txheej txheem kev tshuaj xyuas txhawm rau txhim kho qhov tseeb ntawm kev txheeb xyuas; Lwm cov ntaub ntawv ua tiav kuj tuaj yeem ua raws li cov qauv muab los ntawm tus neeg siv.

(8) Cov ntaub ntawv sim tau muab khaws cia rau hauv cov ntawv nyeem kom yooj yim rau cov neeg siv cov lus nug, thiab tuaj yeem ua tiav ntxiv siv cov ntawv tshaj tawm kev lag luam lossis cov software ua cov lus, thaum tseem txhawb nqa cov ntaub ntawv xa mus hauv is taws nem;

(9) Cov ntaub ntawv nkhaus ntawm cov txheej txheem kev sim tuaj yeem kaw thiab khaws cia, thiab qhov nkhaus tuaj yeem hla thiab muab piv rau kev sib piv yooj yim;

(10) Daim ntawv xeem tuaj yeem luam tawm raws li tus neeg siv khoom xav tau. Cov neeg siv tuaj yeem xaiv cov ntsiab lus ntawm daim ntawv tshaj tawm cov ntaub ntawv yooj yim, cov txiaj ntsig kev sim, thiab kev sim nkhaus kom tau raws li ntau yam kev xav tau;

(11) Lub zeroing digital thiab tsis siv neeg calibration ntawm kev sim quab yuam thiab deformation tau ua tiav, uas pab txhawb kev lag luam thiab txhim kho kev ntseeg siab ntawm lub tshuab. Ntau qhov kev teeb tsa kev teeb tsa tau muab khaws cia rau hauv daim ntawv thov kom txuag tau yooj yim thiab rov qab los;

(12) tuaj yeem siv rau Win7 operating system. Kev tswj ntawm cov txheej txheem kev sim, kev hloov pauv ntawm qhov ceev ntawm crossbeam txav, parameter input, thiab lwm yam kev ua haujlwm tuaj yeem ua tiav siv cov keyboard lossis nas, ua kom yooj yim thiab ceev siv;

(13) Nruab nrog kev tiv thaiv overload thiab tsis siv neeg kaw ua haujlwm, nws tuaj yeem kuaj xyuas cov qauv tawg thiab txiav tawm.

Raws li cov neeg siv khoom sib txawv, cov haujlwm saum toj no software yuav raug kho lossis hloov kho.

6. Software thiab software lag luam interface:

(1) Lub software tuaj yeem khiav ntawm Windows 7 system, thiab tus neeg siv interface nthuav qhia Suav qhov rais qhov system raws li Windows style. Txhua qhov kev sim ua haujlwm tuaj yeem ua tiav los ntawm nas nkag ntawm lub computer screen.

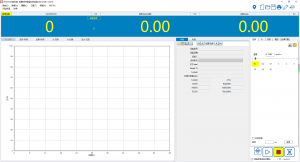

Lub ntsiab interface ntawm lub tshuab kuaj

(Lub software interface yog txawv me ntsis, feem ntau raws li kev muaj tiag)

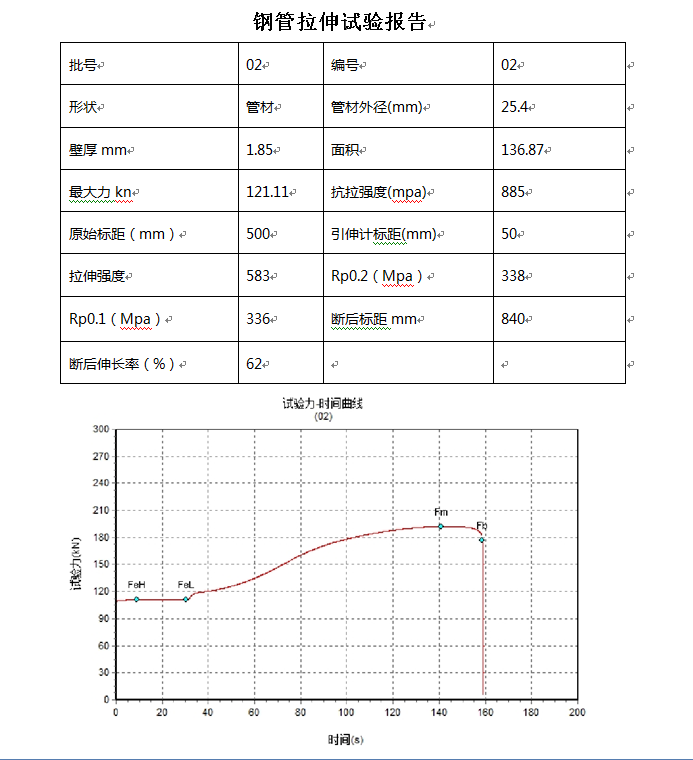

7. Daim ntawv ntsuam xyuas:

Tshawb nrhiav thiab tswj cov ntaub ntawv sim los ntawm cov ntaub ntawv sim cov ntaub ntawv; Customize cov ntsiab lus thiab hom kev sim cov ntaub ntawv los ntawm kev tshaj tawm cov qauv teeb tsa; Los ntawm kev kho cov qauv thiab cov khoom tshwm sim, kev txhawb nqa rau feem ntau ntawm cov qauv kev sim thiab cov txheej txheem tuaj yeem ua tiav; Tom qab thauj ib lossis ntau cov ntaub ntawv xeem cov ntaub ntawv, tsim ib daim ntawv ntsuam xyuas raws li daim ntawv qhia template thiab luam tawm; Txhawb Lo Lus thiab Excel daim ntawv qhia templates, thiab tuaj yeem hloov kho dawb;

(Cov ntaub ntawv tsuas yog siv tau thiab tsis muaj qhov tseem ceeb)

8. Cov cuab yeej tiv thaiv kev nyab xeeb

(1) Thaum lub zog ntsuas siab tshaj 2% -5% ntawm qhov ntsuas siab tshaj plaws, kev tiv thaiv overload tau qhib thiab lub kaw lus raug tshem tawm.

(2) Thaum lub piston nce mus rau qhov chaw siab tshaj, kev tiv thaiv kab mob stroke nres thiab cov roj twj tso kua mis lub cev muaj zog nres.

Main Performance thiab technical indicators

| TSIS MUAJ. | Lub npe qhov project | Tsis muaj |

| 1 | Qhov ntsuas siab tshaj plaws kN | rau pua |

| 2 | Tus tswv tsev | Plaub tus ncej thiab ob lub taub hau ntsia hlau |

| 3 | Cov txheeb ze yuam kev ntawm kev ntsuas quab yuam | ≤ ± 1% ntawm tus nqi qhia |

| 4 | Test quab yuam ntsuas ntau | 2% ~ 100% ntawm qhov ntsuas siab tshaj plaws |

| 5 | Kev tswj qhov ceev ceev tsis tu ncua (N / mm2 · S-1) | 2 ~ 60 |

| 6 | Tsis tu ncua strain tswj ntau yam | 0.00025/s ~ 0.0025/s |

| 7 | Kev tswj qhov ceev ceev tsis tu ncua (mm / min) | 0.5 ~ 50 |

| 8 | clamping system | Hydraulic clamping |

| 9 | Circular specimen clamping diameter range mm | Xaiv ib qho teeb tsa hauv thaj tsam ntawm Φ 6 txog Φ 40 |

| 10 | Flat specimen clamping thickness ntau mm | 0 ~ 15 |

| 11 | Flat qauv clamping dav mm | xya caum |

| 12 | Maximum tensile xeem qhov chaw mm | 550 (loj customizable) |

| 13 | Max compression xeem qhov chaw mm | 500 (loj customizable) |

| 14 | Tswj txee sab nraud qhov ntev mm | 1100 × 620 × 850 hli |

| 15 | Host qhov ntev hauv millimeters | 900 × 630 × 2300 (qhov loj me tuaj yeem hloov kho) |

| 16 | Lub cev muaj zog kW | ob point peb |

| 17 | Host luj kg | ib txhiab thiab tsib puas |

| 18 | Kem center nrug (mm) | plaub puas tsib caug |

| 19 | Sab saum toj thiab qis siab phaj loj mm | Φ160 |

| 20 | Khoov txhawb pas nrig sib nrug mm | 450 (loj customizable) |

| 21 | Khoov txhawb pas nrig dav mm | 140 (loj customizable) |

| 22 | Tso cai khoov degree mm | 100 (loj customizable) |

| 23 | Qhov siab tshaj plaws piston stroke mm | ob puas |

| 24 | Qhov siab tshaj plaws piston txav ceev mm/min | Txog 60 |

| 25 | Kev sim qhov chaw hloov kho ceev mm/min | Txog 150 |

Txheem configuration

| TSIS MUAJ. | Lub npe | Specifications | Qty. | lus hais |

| 1 | tus tswv tsev |

| 1 Teeb | Tus kheej tsim |

| 2 | Servo tswj roj qhov chaw |

| 1 Teeb | Tus kheej tsim |

| 4 | Tswj txee |

| 1 Teeb | Tus kheej tsim |

| 5 | Ntsuas thiab Tswj System |

| 1 Teeb | Tus kheej tsim |

| 6 | Log hais lus sensor |

| 1 pcs | Kev sim dav |

| 7 | Stretching encoder |

| 1 pcs | Jinan |

| 8 | lub computer |

| 1 Teeb | HP |

| 9 | tshuab luam ntawv |

| 1 Teeb | HP |

| 10 | Round specimen puab tsaig mm | Xaiv ib khub hauv qhov ntau ntawm Φ 6- Φ 13, Φ 13- Φ 26, thiab Φ 26- Φ 40 | 1 pcs | Tus kheej tsim

|

| 11 | Flat qauv puab tsaig mm | 0 ~ 15 | 1 pcs | |

| 12 | Compression txuas mm | Φ150 | 1 Teeb | Tus kheej tsim |

| 13 | Roj twj tso kua mis |

| 1 Teeb | Mazzic, Ltalis |

| 14 | hluav taws xob machinery |

| 1 Teeb | Shanghai Songhui |

| 15 | Cov ntaub ntawv technical | Cov neeg siv phau ntawv, packing list, daim ntawv pov thawj ntawm conformity | 1 pcs | Tus kheej tsim |

Cov txheej txheem ua haujlwm:

Cov txheej txheem ua haujlwm rau electro-hydraulic servo kuaj tshuab

1. Pib lub computer thiab nkag mus rau lub software

2. Pib lub hwj chim hloov thiab roj qhov tseem ceeb hloov ntawm electro-hydraulic servo maub los

3. Kho qhov nruab nrab crossbeam ntawm lub tshuab kuaj tus tswv tsev mus rau txoj haujlwm tsim nyog, thiab hloov qhov tsim nyog fixture raws li cov duab, qhov loj me, thiab lub hom phiaj ntawm kev sim ntawm cov qauv.

4. Qhib lub hwj chim hloov ntawm lub twj tso kua mis roj thiab nqa lub tog raj kheej roj ntawm lub tshuab kuaj kom tshem tawm nws qhov hnyav. (Koj tuaj yeem xaiv qhov kev hloov pauv ceev ntawm 10mm / min thiab nias lub khawm [Up] kom nce lub tog raj kheej roj li ntawm 1mm).

5. Nkag mus rau cov ntaub ntawv ntsig txog cov style hauv cov ntaub ntawv version ntawm software.

6. Tom qab clamping cov style mus rau lub puab tsaig sab sauv, rov pib dua tus nqi quab yuam mus rau xoom, kho qhov nruab nrab crossbeam mus rau txoj hauj lwm tsim nyog, clamp lub puab tsaig qis, thiab rov pib dua qhov kev hloov pauv thiab deformation. (Cov style yuav tsum tau clamped rau ntau tshaj 80% ntawm tag nrho cov puab tsaig, thiab tuav ntsug thiab ua raws)

7. Xaiv qhov tsim nyog ceev lossis txoj kev npaj, nyem lub pob 【Start】 hauv software, thiab ua qhov kev sim

Tom qab cov qauv tawg lawm, qhov kev ntsuam xyuas cia li xaus. Txhawm rau saib cov ntaub ntawv sim, nyem rau ntawm cov ntaub ntawv version hauv software saib cov ntaub ntawv xav tau

Tom qab ua tiav ntawm tag nrho cov qauv ntsuas, cov roj kheej kheej piston poob rau hauv qab ntawm lub tog raj kheej roj thiab cov roj qhov tseem ceeb hloov pauv.

8. Tshem tawm cov kev khiav hauj lwm software, kaw lub computer, thiab tua lub hwj chim host.

Nco ntsoov:

1. Cov hlau shavings nyob rau hauv lub puab tsaig ntawm lub tshuab kuaj xyuas yuav tsum tau muab tshem tawm tsis tu ncua kom lub puab tsaig huv si

Thaum ntxuav cov cuab yeej thiab ua kom huv si hauv qhov chaw ua haujlwm, lub zog yuav tsum raug txiav

Thaum lub sij hawm sim, yog tias cov roj twj tso kua mis dheev nres ua haujlwm, cov ntaub ntawv thov yuav tsum tau muab tshem tawm, kuaj xyuas, thiab cov roj twj tso kua mis yuav tsum rov pib dua.

Thaum lub tshuab ntsuas raug ncua ib ntus, cov roj twj tso kua mis lub cev muaj zog yuav tsum tau muab tua, thiab lub rooj zaum ntsuas yuav tsum tau qis dua tom qab qhov kev xeem tiav. Lub piston ntawm lub tog raj kheej roj yuav tsum tsis txhob poob rau hauv qab ntawm lub tog raj kheej thiab ntws tawm ib qho kev ncua deb los pab txhawb kev siv yav tom ntej

5. Tsis txhob cia cov cuab yeej ntub dej los yog nkag mus rau hauv cov khoom ua kua, thiab tiv thaiv cov khoom los ntawm kev co los yog cuam tshuam.

6. Thov tsis txhob tawm hauv chav ua haujlwm thiab nias lub khawm nres thaum muaj xwm txheej ceev

7. Nyob deb ntawm kev cuam tshuam sib nqus

8. Cov neeg ua haujlwm tsis muaj kev tshaj lij tsis raug tso cai los hloov kho cov software program ntawm lub tshuab kuaj

Quality Assurance

Lub tuam txhab lav tias tag nrho cov khoom tsim tawm raws li cov qauv hauv lub tebchaws;

Lub tuam txhab lav tias tag nrho cov khoom siv hauv tsev yog los ntawm cov npe nrov nrog zoo heev;

Lub tuam txhab lav tias tag nrho cov khoom siv txawv teb chaws yog cov khoom qub thiab cov khoom tiag los ntawm lub Hoobkas;

Lub tuam txhab lav tias cov khoom uas muab rau cov neeg siv yog cov khoom qub qub;

Lub tuam txhab lav tias tag nrho cov khoom tawm hauv lub Hoobkas tau raug tshuaj xyuas nruj raws li cov txheej txheem;

Lub tuam txhab cog lus tias yuav txais cov neeg siv khoom tuaj xyuas thiab saib xyuas lub Hoobkas txhua lub sijhawm.

Cov neeg siv kev npaj

Cov kws tshaj lij hauv kev siv computer;

Tus neeg siv yuav tsum qhia meej txog cov kev sim thiab cov ntsiab lus ntawm cov qauv uas qhov kev sim hais txog thiab ua raws;

Muab cov qauv uas tau sim ntawm lub tshuab no rau kev kuaj cov khoom, kev tshuaj xyuas lub Hoobkas, thiab kev ntsuas kev hloov tshuab;

Qhov chaw, lub hauv paus, lub hwj chim, thiab lwm yam yuav tsum tau rau cov khoom installation;

Lub chav kuaj yuav tsum tau nruab nrog cua txias, nrog rau sab hauv tsev kub tswj ntawm 15-25 ℃ thiab av noo <70%;

Lub luag haujlwm rau kev txais, khaws cia, thiab tshem tawm cov khoom;

Kev siv thiab kho

Cov neeg ua haujlwm kuaj tau ruaj khov thiab raug cob qhia yuav tsum tau npaj los ua haujlwm ntawm cov khoom, thiab lwm tus tsis raug tso cai ua haujlwm;

Thaum siv cov khoom, cov neeg ua haujlwm yuav tsum ua raws li kev cob qhia thiab kev taw qhia uas lawv tau txais los ua haujlwm hauv cov txheej txheem kom raug;

Cov neeg khiav dej num yuav tsum paub zoo txog cov qauv kev xeem kom raug txhawm rau txiav txim siab qhov kev xeem tau raug;

Cov neeg ua haujlwm yuav tsum ua tib zoo nyeem phau ntawv tuav tswj thiab software phau ntawv;

Thaum kawg ntawm kev sim, tua lub tshuab kom raug thiab txiav tawm tag nrho cov khoom siv hluav taws xob;

Yog tias nws tus kheej tsim cov khoom siv kho qhov muag tau siv, cov qauv qub ntawm cov khoom yuav tsum tsis txhob hloov pauv lossis puas thaum lub sijhawm teeb tsa;

Yog tias muaj qhov teeb meem txawv txav lossis hluav taws xob tsis ua haujlwm thaum lub sijhawm ua haujlwm ntawm lub tshuab kuaj, thiab lub khawm pib lossis nres tsis ua haujlwm, lub hwj chim yuav tsum raug txiav tam sim ntawd kom tsis txhob siv lub tshuab kuaj ua haujlwm;

Cov ntsia hlau thiab kis tau tus mob yuav tsum tsis tu ncua coated nrog lubricating roj kom tsis txhob qhuav kev sib txhuam;

Yog tias cov khoom ua haujlwm tsis zoo, thov hu rau peb lub chaw pabcuam neeg siv khoom raws sijhawm thiab tsis txhob cuam tshuam ncaj qha yam tsis muaj kev tso cai;

Tsis txhob hloov cov khoom ntawm koj tus kheej.

SHANDONG DRICK INSTRUMENTS CO., LTD

Tuam txhab Profile

Shandong Drick Instruments Co., Ltd, feem ntau yog koom nrog hauv kev tshawb fawb thiab kev tsim kho, tsim khoom thiab muag cov cuab yeej ntsuas.

Lub tuam txhab tsim nyob rau hauv 2004.

Cov khoom siv hauv kev tshawb fawb txog kev tshawb fawb, cov chaw soj ntsuam zoo, cov tsev kawm qib siab, ntim, ntawv, luam ntawv, roj hmab thiab yas, tshuaj, khoom noj, tshuaj, textiles, thiab lwm yam lag luam.

Drick them nyiaj mloog mus rau kev cog qoob loo thiab pab pawg tsim, ua raws li kev txhim kho lub tswv yim ntawm kev tshaj lij, kev mob siab.pragmatism, thiab kev tsim kho tshiab.

Ua raws li cov neeg siv khoom-oriented hauv paus ntsiab lus, daws cov kev xav tau ceev tshaj plaws thiab cov tswv yim ntawm cov neeg siv khoom, thiab muab cov kev daws teeb meem thawj zaug rau cov neeg siv khoom nrog cov khoom zoo thiab cov cuab yeej siv siab heev.