Na'urar Gwajin Hydraulic Universal WAW-600D Mai Na'urar Kwamfuta Mai Sarrafa

Takaitaccen Bayani:

WAW-600D Microcomputer Controlled Hydraulic Universal Testing Machine Samfuran Samfurin: Babban jikin WAW-600D microcomputer sarrafawa electro-hydraulic servo hydraulic test machine yana ɗaukar silinda saukar nau'in babban tsarin jiki, galibi ana amfani dashi don gwaje-gwajen aikin injiniya kamar tashin hankali, matsawa. , Lankwasawa da kayan ƙarfe, kayan da ba na ƙarfe ba, sassan samfuri, abubuwan da aka gyara, sassan tsarin, da daidaitattun sassa. Idan an sanye su da na'urorin muhalli, wannan jerin...

WAW-600D Microcomputer Mai SarrafaNa'urar Gwajin Ruwa ta Duniya

Bayanin Samfuri:

Babban jikin WAW-600D microcomputer sarrafawa electro-hydraulic servo na'ura mai ba da hanya tsakanin hanyoyin sadarwa na duniya yana ɗaukar nau'in silinda saukar nau'in babban tsarin jiki, galibi ana amfani dashi don gwaje-gwajen aikin injiniya kamar tashin hankali, matsawa, lanƙwasa kayan ƙarfe, kayan da ba ƙarfe ba, samfur. sassa, sassa, sassa na tsari, da daidaitattun sassa.

Idan an sanye su da na'urorin muhalli, wannan jerin injunan gwaji kuma za su iya yin gwaje-gwajen juzu'i, matsawa, da lankwasawa a cikin wannan muhallin. Misali: matsanancin zafi mai zafi, ƙarancin zafin jiki, matsawa da sauran gwaje-gwaje.

Ya dace da ƙarfe, ƙarfe, kayan gini, cibiyoyin dubawa masu inganci, kiyaye ruwa da wutar lantarki, gadoji na manyan hanyoyi, cibiyoyin bincike, injiniyan injiniya a kwalejoji da jami'o'i, da sauran masana'antu, ma'adinai, masana'antu, da cibiyoyin gwaji da bincike.

Ma'auni na masana'antu da dubawa don samfurori

GB2611 "Bukatun Fasaha na Gabaɗaya don Injin Gwaji"

JJG139 “Tunsile, Matsi, daInjin Gwajin Duniya"

Ma'auni na hanyar gwaji masu dacewa

Ayyukan gwaji da sarrafa bayanai sun cika buƙatun ɗaruruwan ma'auni kamar GB/T228 "Hanyar Gwajin Tensile don Kayan ƙarfe a Zazzaɓin ɗaki", GB/T7314 "Hanyar Gwajin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfe a Zazzabi", GB/T232 "Bending Hanyar Gwaji don Kayan Karfe", da sauransu. Kuma hanyoyin sarrafa bayanai waɗanda suka dace da ma'auni daban-daban za a iya daidaita su gwargwadon bukatun abokin ciniki.

Babban alamun fasaha

1 Mai watsa shiri

Babban injin yana ɗaukar nau'in silinda mai ɗorawa na ƙasa, tare da shimfidar sararin samaniya da ke sama da babban injin, da matsawa da sararin gwajin lankwasawa tsakanin ƙananan giciye na babban injin da kayan aiki.

2 Tsarin watsawa

Ɗagawa na tsakiya na tsakiya yana ɗaukar motar da ke motsawa ta hanyar motar sarkar don juya dunƙule, daidaita matsayi na tsaka-tsakin tsaka-tsakin tsakiya da kuma cimma daidaito na tashin hankali da sararin samaniya.

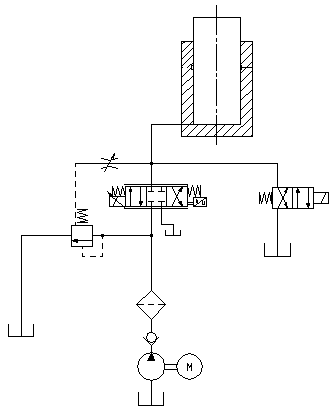

An nuna ka'idar hydraulic na tsarin na'ura mai aiki da karfin ruwa a cikin Hoto 2, wanda shine tsarin sarrafa saurin man fetur mai daidaitawa.

Hoto 2 Tsarin tsari na ruwa

Man na'ura mai aiki da karfin ruwa a cikin tankin mai ana motsa shi ta hanyar motar don shiga da'irar mai, kuma yana gudana ta hanyar bawul ta hanya ɗaya, matatar mai mai ƙarfi mai ƙarfi, rukunin matsi daban-daban, bawul ɗin servo, sannan ya shiga cikin silinda mai. Kwamfuta tana aika siginar sarrafawa zuwa bawul ɗin servo mai daidaitawa don sarrafa buɗewa da jagorar madaidaicin bawul ɗin servo, ta haka ne ke sarrafa kwarara cikin silinda mai da samun ikon sarrafa ƙarfin gwajin saurin sauri, matsananciyar gudu, da sauransu.

4. Tsarin wutar lantarki da tsarin sarrafawa:

(1) Babban abubuwan haɗin tushen mai sarrafa servo duk an shigo da kayan asali na asali tare da ingantaccen aiki.

(2) Yana da ayyuka na kariya kamar nauyin kaya, wuce gona da iri, wuce gona da iri, iyakoki na sama da ƙasa, da tsayawar gaggawa.

(3) Mai sarrafawa da aka gina bisa fasahar PCI yana tabbatar da cewa injin gwajin zai iya samun ikon sarrafa madaidaicin rufaffiyar sigogi kamar ƙarfin gwaji, nakasar samfuri, da ƙaurawar katako, kuma yana iya yin gwaje-gwaje kamar ƙarfin gwajin saurin sauri, ci gaba da sauri. ƙaura, matsananciyar saurin gudu, madauwari mai ɗaukar nauyi, da sake zagayowar nakasar saurin gudu. Sauya sauƙi tsakanin hanyoyin sarrafawa iri-iri yana yiwuwa.

(4) A ƙarshen gwajin, ana iya yin shi da hannu ko kuma ta atomatik a mayar da shi zuwa matsayin farko na gwajin a babban gudun.

(5) Ya sami sifili na zahiri na gaskiya, samun gyare-gyare, da canzawa ta atomatik, sifili, daidaitawa, da adana ma'aunin ƙarfin gwaji, ba tare da haɗin haɗin daidaitaccen analog ba, kuma kewayar sarrafawa yana haɗawa sosai.

(6) Da'irar sarrafa wutar lantarki tana bin ka'idojin ƙasa da ƙasa kuma tana bin ka'idodin lantarki na injin gwaji na ƙasa. Yana da ƙarfin hana tsangwama mai ƙarfi, yana tabbatar da kwanciyar hankali na mai sarrafawa da daidaiton bayanan gwaji.

(7) An sanye shi da hanyar sadarwa ta hanyar sadarwa, yana iya yin watsa bayanai, adanawa, rikodin bugu, da bugu na watsawa na cibiyar sadarwa, kuma ana iya haɗa shi da LAN na ciki ko cibiyar sadarwar Intanet na kamfanin.

5. Bayanin manyan fasalulluka na software

Ana amfani da wannan ma'auni da software na sarrafawa don microcomputer sarrafawa electro-hydraulic servo hydraulic universal test machine don gudanar da gwaje-gwaje na karfe da na ƙarfe daban-daban, cikakken ma'auni da nuni na ainihin lokaci, sarrafa lokaci da sarrafa bayanai, fitarwar sakamako da sauran ayyuka bisa ga zuwa ma'auni masu dacewa.

(1) Gudanar da tushen izini, inda masu aiki a matakai daban-daban ke da izini daban-daban na aiki da samun dama ga menus da sauran abun ciki. Wannan ba kawai yana sauƙaƙewa, sauƙaƙewa, da saurin ayyuka ga masu aiki na yau da kullun ba, har ma yana kare tsarin yadda ya kamata;

(2) Ma'auni na ainihi da nunin ƙarfin gwaji, ƙimar kololuwa, ƙaura, lalacewa da sauran sigina; An sami nasarar tattarawa da sarrafawa na ainihi akan dandamali; Kuma an sami madaidaicin lokaci da samfuri mai sauri;

(3) Nunin allo na ainihin lokaci na nau'ikan gwaji daban-daban kamar nakasar kaya da matsuguni, wanda za'a iya canzawa kuma ana lura dashi a kowane lokaci. Zuƙowa a ciki da waje yana da dacewa sosai;

(4) Kwamfuta tana da ayyuka kamar adanawa, saitawa, da loda sigogin gwaji. Zeroing, calibration, da sauran ayyuka ana aiwatar da su ta hanyar software, kuma kowace siga ana iya adanawa cikin sauƙi da shigo da su, yana sauƙaƙa sauyawa tsakanin na'urori masu auna firikwensin da yawa akan ma'aikaci ba tare da iyakancewa akan adadin na'urori ba;

(5) Taimakawa hanyoyin sarrafawa da yawa, gami da buɗe madaidaicin madaidaicin matsuguni, ƙarfin saurin ci gaba, matsananciyar saurin gudu, da sauran hanyoyin sarrafa madauki; Kuma samar da madaidaitan maƙallan tunani yayin aiwatar da aikin gyara madaidaicin madaidaicin rufaffiyar ma'aikata na ci gaba, ta yadda masu amfani za su iya lura da tasirin kowane siga akan tasirin rufaffiyar.

(6) An sanye shi da tsarin ƙwararrun ƙwararrun ƙwararrun don saita hanyoyin sarrafa tsarin gwaji, samar da ƙwararrun masu amfani da masu shirye-shirye na atomatik. Masu amfani na iya sassauƙa haɗa hanyoyin sarrafawa da yawa da saurin sarrafawa bisa ga ainihin buƙatu da ƙa'idodi, da haɓaka shirye-shiryen sarrafawa waɗanda suka dace da bukatunsu. Software na aunawa da sarrafawa za su sarrafa tsarin gwaji ta atomatik bisa ga saitunan mai amfani.

(7) Binciken bayanai ta hanyar hulɗar ɗan adam da kwamfuta. Hanyar sarrafawa ta dace da buƙatun ma'auni da aka yi amfani da su sosai kuma za su iya ƙididdige sigogin ayyuka daban-daban ta atomatik kamar su modules na roba, ƙarfin yawan amfanin ƙasa, da ƙayyadaddun ƙarfin tensile mara daidaituwa. Hakanan za'a iya shigar da shi da hannu a cikin tsarin bincike don inganta daidaiton bincike; Hakanan za'a iya aiwatar da wasu sarrafa bayanai bisa ga ƙa'idodin da mai amfani ya bayar.

(8) Ana adana bayanan gwaji a cikin fayilolin rubutu don dacewa da tambayoyin mai amfani, kuma ana iya ƙara sarrafa su ta amfani da duk wani rahoton kasuwanci na gaba ɗaya ko software na sarrafa kalmomi, yayin da kuma sauƙaƙe watsa bayanai ta hanyar intanet;

(9) Za'a iya yin rikodin bayanan tsarin gwaji da adanawa, kuma za'a iya yin la'akari da ma'auni kuma idan aka kwatanta da sauƙi mai sauƙi;

(10) Ana iya buga rahoton gwajin a cikin tsarin da mai amfani ya buƙaci. Masu amfani za su iya zaɓar abin da ke cikin rahoton ya fitar da ainihin bayanan, sakamakon gwaji, da maƙallan gwaji don biyan buƙatu daban-daban;

(11) Sifili na dijital da daidaitawa ta atomatik na ƙarfin gwaji da nakasar da aka samu, wanda ke sauƙaƙe aiki da haɓaka amincin injin. Ana adana saitunan tsarin sigina daban-daban a cikin nau'in fayil don sauƙi mai sauƙi da farfadowa;

(12) Za a iya amfani da Win7 tsarin aiki. Gudanar da tsarin gwaji, canje-canje a cikin saurin motsi na crossbeam, shigarwar sigogi, da sauran ayyuka za a iya kammala su ta amfani da maɓalli ko linzamin kwamfuta, yana sa ya dace da sauri don amfani;

(13) An sanye shi da kariya mai yawa da aikin kashewa ta atomatik, yana iya gano karaya ta atomatik kuma yana rufe ta atomatik.

Dangane da buƙatun mai amfani daban-daban, ana iya gyara ko gyara ayyukan software na sama.

6. Kayan aikin software da software:

(1) Software na iya aiki akan tsarin Windows 7, kuma mai amfani yana ba da tsarin taga na kasar Sin daidai da salon Windows. Ana iya kammala duk ayyukan gwaji ta hanyar shigar da linzamin kwamfuta akan allon kwamfuta.

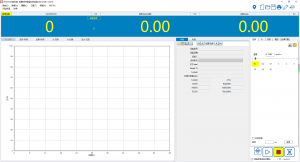

Babban dubawa na injin gwaji

(Kayan aikin software ya ɗan bambanta, galibi bisa ga gaskiya)

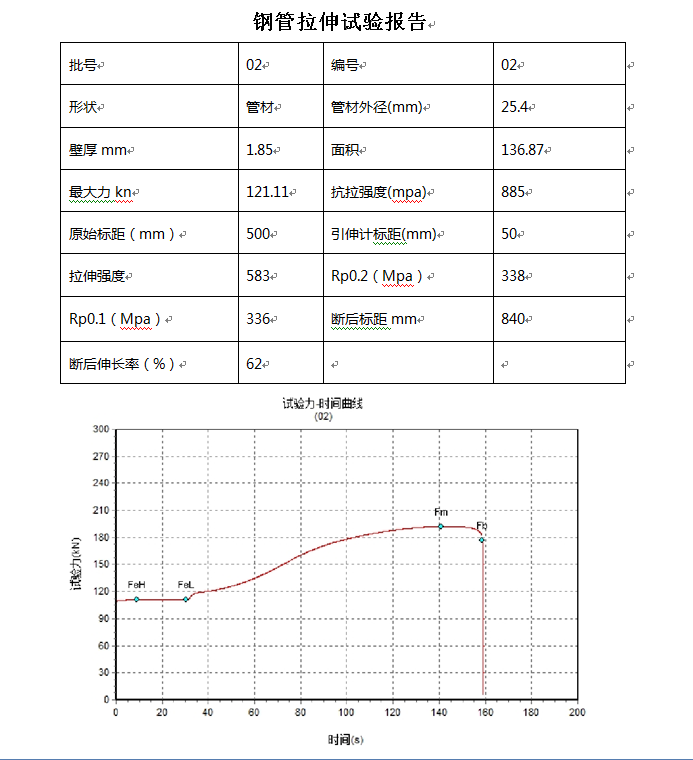

7. Rahoton gwaji:

Bincika da sarrafa bayanan gwaji ta fayilolin bayanan gwaji; Keɓance abun ciki da tsarin rahotannin gwaji ta hanyar saitunan samfuri na rahoton; Ta hanyar gyare-gyaren ƙididdiga da abubuwan sakamako, ana iya samun goyon baya ga mafi yawan matakan gwaji da hanyoyin; Bayan loda fayilolin bayanan gwaji ɗaya ko fiye, samar da rahoton gwaji bisa ga samfurin rahoton kuma buga shi; Yana goyan bayan samfuran rahoton Kalma da Excel, kuma ana iya gyara su kyauta;

(Bayanan don tunani ne kawai kuma ba su da wani amfani mai amfani)

8. Na'urar kariya ta tsaro

(1) Lokacin da ƙarfin gwajin ya wuce 2% -5% na matsakaicin ƙarfin gwaji, ana kunna kariya ta wuce gona da iri kuma ana sauke tsarin.

(2) Lokacin da fistan ya tashi zuwa matsayi na sama, kariyar bugun jini yana tsayawa kuma injin famfo mai ya tsaya.

Babban aikin da alamun fasaha

| A'A. | Sunan aikin | Ma'auni |

| 1 | Matsakaicin ƙarfin gwaji kN | dari shida |

| 2 | Tsarin rundunar | ginshiƙai huɗu da ƙusoshin gubar guda biyu |

| 3 | Kuskuren dangi na nunin ƙarfin gwaji | ≤ ± 1% na ƙimar da aka nuna |

| 4 | Gwajin ma'aunin ma'aunin ƙarfi | 2% ~ 100% na iyakar ƙarfin gwaji |

| 5 | Matsakaicin sarrafa saurin damuwa na yau da kullun (N/mm2 · S-1) | 2 ~ 60 |

| 6 | Kewayon sarrafa iri na dindindin | 0.00025/s~0.0025/s |

| 7 | Matsakaicin sarrafa gudun hijira na dindindin (mm/min) | 0.5-50 |

| 8 | clamping tsarin | Haɗaɗɗen ruwa |

| 9 | Da'irar da'irar manne diamita kewayon mm | Zaɓi kowane saiti tsakanin kewayon % 6 zuwa % 40 |

| 10 | Flat samfurin manne kauri kewayon mm | 0 ~ 15 |

| 11 | Lebur samfurin manne nisa mm | saba'in |

| 12 | Matsakaicin sararin gwaji mai ƙarfi mm | 550 (mai girman girman girman) |

| 13 | Matsakaicin matsawa sarari gwajin mm | 500 (mai girman girman girman) |

| 14 | Sarrafa ma'auni na waje mm | 1100×620×850 |

| 15 | Girman rundunar a cikin millimeters | 900 × 630 × 2300 (girman za a iya musamman) |

| 16 | Motar kW | maki biyu uku |

| 17 | Mai masaukin nauyi kg | dubu daya da dari biyar |

| 18 | Nisan tsakiyar ginshiƙi (mm) | dari hudu da hamsin |

| 19 | Girman farantin matsi na sama da ƙasa mm | Φ160 |

| 20 | Lankwasawa goyon bayan tazarar sanda mm | 450 (mai girman girman girman) |

| 21 | Lankwasawa goyon bayan sanda nisa mm | 140 (size iya daidaita) |

| 22 | Digiri lanƙwasawa da aka yarda mm | 100 (size customizable) |

| 23 | Matsakaicin bugun fistan mm | dari biyu |

| 24 | Matsakaicin motsin piston mm/min | Kusan 60 |

| 25 | Gudun daidaitawar sarari na gwaji mm/min | Kusan 150 |

Daidaitaccen tsari

| A'A. | Suna | Ƙayyadaddun bayanai | Qty | kalamai |

| 1 | mai masaukin baki |

| 1 Saita | Samar da kai |

| 2 | Madogararsa mai sarrafa Servo |

| 1 Saita | Samar da kai |

| 4 | Gudanar da majalisar |

| 1 Saita | Samar da kai |

| 5 | Aunawa da Tsarin Kulawa |

| 1 Saita | Samar da kai |

| 6 | Dabarun magana firikwensin |

| 1pcs | Gwaji mai faɗi |

| 7 | Mai rikodin rikodin |

| 1pcs | Jinan |

| 8 | kwamfuta |

| 1 Saita | HP |

| 9 | printer |

| 1 Saita | HP |

| 10 | Zagaye samfurin jaws mm | Zaɓi kowane nau'i-nau'i tsakanin kewayon % 6- Φ 13, Φ 13- % 26, da Φ 26- Φ 40 | 1pcs | Samar da kai

|

| 11 | Flat samfurin jaws mm | 0 ~ 15 | 1pcs | |

| 12 | Matsa lamba mm | Φ150 | 1 Saita | Samar da kai |

| 13 | Ruwan mai |

| 1 Saita | Mazzic, Italiya |

| 14 | injinan lantarki |

| 1 Saita | Shanghai Songhui |

| 15 | Takardun fasaha | Littafin mai amfani, lissafin tattarawa, takardar shedar daidaito | 1pcs | Samar da kai |

Hanyoyin aiki:

Hanyoyin aiki don injin gwajin lantarki-hydraulic servo

1. Fara kwamfutar kuma shigar da software

2. Fara maɓallin wutar lantarki da babban maɓallin mai na mai kula da servo-hydraulic servo

3. Daidaita tsaka-tsakin tsaka-tsakin na'urar gwajin gwajin zuwa matsayi mai dacewa, kuma maye gurbin abin da ya dace daidai da siffar, girman, da manufar gwaji na samfurin.

4. Kunna wutar lantarki na famfon mai kuma ɗaga silinda mai na injin gwajin don kawar da nauyin kansa. (Zaka iya zaɓar gudun gudun hijira na 10mm/min kuma danna maɓallin [Up] don ɗaga silinda mai da kusan 1mm).

5. Shigar da bayanai masu dacewa game da salo a cikin sigar bayanan software.

6. Bayan danne salon a kan muƙamuƙi na sama, sake saita ƙimar ƙarfin zuwa sifili, daidaita tsaka-tsakin tsaka-tsaki zuwa matsayin da ya dace, danna ƙananan muƙamuƙi, da sake saita ƙaura da nakasar. (Salon ya kamata a matse shi zuwa sama da 80% na duk jaws, kuma a kiyaye shi a tsaye da daidaitawa)

7. Zaɓi saurin da ya dace ko shirin, danna maɓallin 【 Start 】 a cikin software, sannan gudanar da gwajin.

Bayan samfurin karaya, gwajin ya ƙare ta atomatik. Don duba bayanan gwaji, danna kan sigar bayanai a cikin software don duba bayanan da ake buƙata

Bayan kammala duk gwaje-gwajen samfur, piston silinda mai ya faɗi ƙasan silinda mai kuma ana kashe babban maɓallin mai.

8. Fita daga software na aiki, kashe kwamfutar, kuma kashe wutar lantarki.

Hankali:

1. Ya kamata a rika cire askin karfen da ke cikin muƙamuƙi na na'urar gwaji akai-akai don kiyaye tsaftar muƙamuƙi

Lokacin tsaftace kayan aiki da kiyaye tsabta a cikin yanayin aiki, ya kamata a cire haɗin wutar lantarki

Yayin gwajin, idan famfon mai ya daina aiki ba zato ba tsammani, sai a sauke nauyin da aka yi amfani da shi, a duba, sannan a sake kunna famfon mai.

Idan aka dakatar da injin gwajin na wani dan lokaci, sai a kashe injin famfo mai, sannan a sauke bencin gwajin bayan an gama gwajin. Piston na Silinda mai bai kamata ya faɗi ƙasan silinda ba kuma ya gudana ta wani nisa don sauƙaƙe amfani da gaba

5. Ka guji barin kayan aikin su yi ruwa ko kuma su hadu da abubuwan ruwa, da kuma hana kayan aiki daga girgiza ko tasiri.

6. Don Allah kar a fita daga ɗakin aiki kuma danna maɓallin dakatar da gaggawa idan akwai gaggawa

7. Nisantar tsangwama na maganadisu

8. Ba a ba da izinin ma'aikatan fasaha ba su canza tsarin software na injin gwaji

Tabbacin inganci

Kamfanin ya ba da tabbacin cewa an samar da duk samfuran daidai da daidaitattun ƙa'idodin ƙasa;

Kamfanin yana ba da garantin cewa duk kayan haɗin gida sun fito ne daga sanannun samfuran da ke da inganci mai kyau;

Kamfanin ya ba da tabbacin cewa duk kayan haɗin gwiwar waje na asali ne kuma samfurori na gaske daga masana'anta;

Kamfanin ya ba da tabbacin cewa samfuran da aka ba wa masu amfani sabbin injinan asali ne;

Kamfanin ya ba da garantin cewa duk samfuran da ke barin masana'anta suna yin cikakken bincike bisa ga hanyoyin;

Kamfanin ya yi alkawarin karɓar abokan ciniki don ziyarta da kuma kula da masana'anta a kowane lokaci.

Yanayin shirye-shiryen mai amfani

ƙwararrun ma'aikata a aikace-aikacen kwamfuta;

Ya kamata mai amfani ya fayyace hanyoyin gwajin da daidaitattun cikakkun bayanai waɗanda gwajin ke nufi da bi;

Samar da samfuran da aka gwada akan wannan na'ura don gwajin samfur, binciken masana'anta, da gwajin daidaitawar injin;

Wurin, tushe, samar da wutar lantarki, da dai sauransu da ake buƙata don shigarwa na samfur;

dakin gwaje-gwaje ya kamata a sanye shi da kwandishan, tare da sarrafa zafin jiki na cikin gida tsakanin 15-25 ℃ da zafi <70%;

Wanda ke da alhakin karɓa, adanawa, da ƙaura;

Amfani da kulawa

Kafaffen da horar da ma'aikatan gwaji dole ne a shirya don sarrafa samfurin, kuma wasu ba a yarda su yi aiki da shi ba;

Lokacin amfani da samfurin, masu aiki ya kamata su bi horo da jagorar da suka samu don sarrafa shi a daidai hanya;

Masu aiki su kasance ƙwararrun ma'auni na gwajin daidai don tantance sakamakon gwajin daidai;

Masu aiki dole ne su karanta a hankali littafin jagora da littafin software;

A ƙarshen gwajin, kashe na'urar a cikin tsari daidai kuma yanke duk hanyoyin wutar lantarki;

Idan an yi amfani da kayan taimako na gwajin da aka yi da kai, dole ne a canza tsarin asalin samfurin ko lalacewa yayin shigarwa;

Idan akwai wani yanayi mara kyau ko gazawar wutar lantarki yayin aikin na'urar, kuma maɓallin farawa ko tsayawa ba ya aiki, to sai a yanke wutar nan take don dakatar da injin gwajin aiki;

Ya kamata a rufe kullun da sassan watsawa akai-akai tare da mai mai mai don hana bushewar gogayya;

Idan samfurin ya yi kuskure, tuntuɓi sashen sabis na abokin ciniki a kan lokaci kuma kar a sake haɗa shi kai tsaye ba tare da izini ba;

Kada ku canza samfur da kanku.

Abubuwan da aka bayar na SHANDONG DRICK INSTRUMENTS CO., LTD

Bayanin Kamfanin

Shandong Drick Instruments Co., Ltd, ya fi tsunduma cikin bincike da haɓakawa, masana'antu da siyar da kayan gwaji.

Kamfanin da aka kafa a 2004.

Ana amfani da samfurori a sassan binciken kimiyya, cibiyoyin bincike masu inganci, jami'o'i, marufi, takarda, bugu, roba da robobi, sunadarai, abinci, magunguna, masaku, da sauran masana'antu.

Drick yana mai da hankali ga haɓaka gwaninta da ginin ƙungiya, yana bin ra'ayin haɓaka ƙwarewar ƙwarewa, sadaukarwa.pragmatism, da ƙima.

Yin riko da ka'idar abokin ciniki, warware mafi gaggawa da bukatun abokan ciniki, da samar da mafita na farko ga abokan ciniki tare da samfurori masu inganci da fasaha na ci gaba.