DRK268 Ƙimar Ƙimar Ƙimar Iskar Gwajin Aiki

Takaitaccen Bayani:

Lambobin Tsaro na Abun ciki Babi na 1 Bayanin kuɗi 1.1 bayyani 1.2 manyan fasali 1.3 manyan ƙayyadaddun bayanai da fihirisar fasaha 1.4 mahallin aiki da yanayi Babi na 2 Tsari da ƙa'idar aiki 2.1 ƙirar ƙirar samfur Maɓallin sarrafa wutar lantarki Babi na 4 Gwajin aikin 4.1 duba kafin farawa 4.2 ganowa bayan farawa 4.3 gwajin aiki Chapter 5 Common fau...

Abun ciki

Lambar aminci

Babi na 1Csake gyara bayanai

1.1 dubawa

1.2 babban fasali

1.3 manyan ƙayyadaddun bayanai da ƙididdiga na fasaha

1.4 yanayin aiki da yanayi

Babi na 2Stsari da ka'idar aiki

2.1 zane tsarin samfurin

2.2 manyan abubuwa

2.3 ka'idar aiki na kayan aiki

Babi na 3Key bayanin aikin

Bayanin aiki na maɓallin sarrafa wutar lantarki

Babi na 4Test aiki

4.1 duba kafin farawa

4.2 ganowa bayan farawa

4.3 gwajin aiki

Babi na 5CLaifin ommon da Magani

Babi na 6Manntenance na kayan aiki

TsaroCode

Wsana'a

A kowane lokaci, kar a buɗe motherboard tare da toshe wutar lantarki a ciki.

A lokacin gwajin, ba za a sanya al'amuran waje a cikin tsaga ba

A lokacin gwajin, idan aikin kowane matsayi ya kasance mara kyau, dole ne a dakatar da gwajin don gano dalilin kuskuren da kuma kawar da shi kafin ci gaba da gwajin.

A cikin yanayin tsawa, don Allah kar a toshe kuma toshe wayar ƙasa, layin wutar lantarki da sauran madugu waɗanda ƙila a haɗa su da duniyar waje.

Idan ba a katse wutar lantarki ba, kar a toshe kowane sassa masu rai da wayoyi.

ƙwararrun ma'aikata ko masu izini ba a yarda su buɗe harsashin samfurin ba.

Lokacin da aka tarwatsa sassan cikin kayan aikin, dole ne a cire layin wutar lantarki don tabbatar da cewa an kashe babban injin.

A cikin kowane irin kayan aiki da hatsarori na aminci na mutum wanda ya haifar ta hanyar keta gargaɗin da ke sama, duk sakamakon da kanmu zai ɗauka.

Babi na 1PtsariIlabari

1.1 Bayani

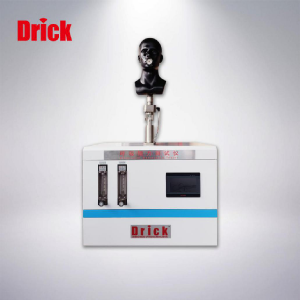

Ana amfani da shi don gano maƙarar iska na bawul ɗin numfashi na nau'in tacewa mai sarrafa kansa. Ya dace da duba lafiyar lafiyar aiki

Cibiyar, cibiyar duba lafiyar sana'a, rigakafin cututtuka da cibiyar kulawa, masana'antun numfashi, da dai sauransu.

Kayan aiki yana da halaye na ƙaƙƙarfan tsari, cikakkun ayyuka da aiki mai dacewa. Kayan aiki yana ɗaukar microcomputer guntu guda ɗaya

Ikon Microprocessor, nunin allo mai launi.

1.2. Babban fasali

1.2.1 babban ma'anar launi tabawa, mai sauƙin aiki.

1.2.2 na'urar firikwensin matsa lamba yana da babban hankali kuma ana amfani dashi don tattara matsa lamba na bayanai.

1.2.3 babban madaidaicin iskar gas na iya auna daidai yawan kwararar iskar gas na bawul ɗin karewa.

Na'urar daidaita matsi mai dacewa da sauri.

1.3 Babban ƙayyadaddun bayanai da ƙididdiga na fasaha

1.3.1 ƙarfin buffer ba zai zama ƙasa da lita 5 ba

1.3.2 kewayon: - 1000pa-0pa, daidaito 1%, ƙuduri 1pA

1.3.3 gudun famfo na injin famfo yana kusan 2L / min

1.3.4 kwarara mita kewayon: 0-100ml / min.

1.3.5 wutar lantarki: AC220 V, 50 Hz, 150 W

1.3.6 gaba ɗaya girma: 610 × 600 × 620mm

1.3.7 nauyi: 30kg

1.4 Yanayin aiki da yanayi

1.4.1 kewayon sarrafa zafin jiki: 10 ℃~ 35 ℃

1.4.2 dangi zafi ≤ 80%

1.4.3 babu wani rawar jiki, matsakaici mai lalata da kuma tsangwama mai ƙarfi na lantarki a cikin mahallin da ke kewaye.

1.4.4 wutar lantarki: AC220 V ± 10% 50 Hz

1.4.5 grounding bukatun: da grounding juriya ne kasa da 5 Ω.

Babi na 2 sassa da ƙa'idar aiki

2.1. Manyan abubuwan da aka gyara

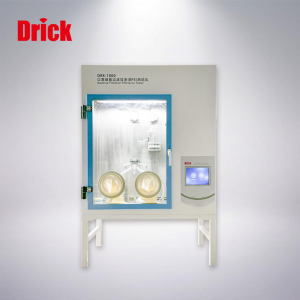

Tsarin waje na kayan aiki yana kunshe da harsashi na kayan aiki, gwajin gwaji da panel na aiki; tsarin ciki na kayan aiki yana kunshe da tsarin sarrafa matsa lamba, CPU data processor, na'urar karatun matsa lamba, da dai sauransu.

2.2 ka'idar aiki na kayan aiki

Ɗauki hanyoyin da suka dace (kamar yin amfani da sealant), hatimi samfurin bawul ɗin numfashi a kan na'urar gwajin bawul ɗin iska a cikin iska, buɗe fam ɗin injin, daidaita bawul ɗin daidaita matsi, sanya bawul ɗin numfashi ya ɗauki matsa lamba na - 249pa, da ganowa. kwararar kwararar bawul din exhalation.

Babi na 3 gwajin aiki

3. Duba kafin farawa

3.1.1 duba ko filogin wutar mai watsa shiri yana da ƙarfi a ciki.

3.1.2 duba cewa an shigar da kayan aiki a tsaye.

3.1.3 duba cewa an shigar da na'urar motsi a tsaye.

3.1.5 duba ko an haɗa tushen iska kuma a buɗe

3.2 dubawa bayan farawa

3.2.1 iko akan mai watsa shiri.

3.2.2 duba ko allon taɓawa mai launi yana nunawa akai-akai, in ba haka ba a duba ko kewaye ta sako-sako.

3.2.3 duba ko kayan aikin yana da ƙararrawa mara kyau.

3.3 gwajin aiki

Nunin allon taɓawa launi ne, kuma ayyukan kowane maɓalli da allon nuni sune kamar haka:

3.3.1 maraba da dubawa

Danna gwaji don shigar da kowane dubawa.

3.3.2 aiki dubawa

Maɓalli na aiki:

Saita: zai tsaya kai tsaye lokacin da aka kai matsi na saiti, kuma za a ɗauki gazawar gwajin azaman saiti na ƙarshe.

[gwaji]: fara / dakatar da gwajin.

Share: goge bayanan mara kyau guda ɗaya.

[Clear]: Ana amfani da shi don share matsi

Babi4. Hanyar gwaji:

4.1. Danna Saita kuma saita sigogi bisa ga ma'auni.

4.2. Shigar da samfurin, hatimi da kyau, kuma danna gwaji. Daidaita bawul ɗin daidaitawa zuwa saita ƙimar matsa lamba, kuma gwajin zai tsaya ta atomatik.

4.3. Duban bayanai

Leakage, matsakaicin, ƙarami, matsakaita

4.4. dubawar tambaya

Ana amfani da maɓallan [na baya] da [na gaba] don bincika bayanan ƙungiyar da ta gabata da na gaba bi da bi, kuma maɓallan [shafi na baya da na gaba] ana amfani da su don bincika bayanan da suka dace na ƙungiyar kowane lokaci. Danna maɓallin [Print] don buga duk bayanai da bayanan ƙididdiga masu dacewa da rukunin tambaya na yanzu. Latsa maɓallin sharewa don share duk bayanai lokacin da ƙarancin ƙwaƙwalwar ajiya.

Fita don komawa zuwa babban dubawa kuma gwada don shigar da ƙirar aiki.

Babi na 5. Laifi gama gari da Magani

5.1 ciki na kayan aiki ba daidai ba ne kuma matsa lamba ba zai iya tashi ba

Bincika ko famfon iskar a kwance.

5.2 ƙimar matsa lamba bai canza ba yayin gwajin

Bincika idan babban allon wayar ba ya kwance. Idan sako-sako ne, toshe shi da ƙarfi

Duba ko an kunna na'urar motsi.

5.3 akwai manyan bambance-bambance a cikin bayanan gwaji

Da fatan za a tuntuɓi masana'anta don jagora da gyara.

Babi na 6 kula da kayan aiki

6.1 kiyaye kayan aiki da tsarin kula da tsabta da tsabta.

6.2 hana yawan zafin jiki, zafi mai yawa, ƙura, kafofin watsa labaru masu lalata, ruwa, da dai sauransu daga shiga cikin injin ko tsarin sarrafawa.

6.3 bincika akai-akai don kiyaye amincin sassa da abubuwan haɗin gwiwa.

6.4 an daidaita ƙimar alamar matsin lamba na kayan aiki kafin barin masana'anta. Ba a ba da izinin tabbatarwa da ƙwararrun ma'aikatan ba su daidaita ba bisa ƙa'ida ba, in ba haka ba, ma'aunin ƙarfin na'urar ba zai zama daidai ba.

6.5 yin aiki mai kyau na gyaran kayan aiki akai-akai don tabbatar da daidaiton ƙimar ma'aunin kayan aiki.

6.6 ba ƙwararrun ƙwararrun ƙwararrun ƙwararru da ma'aikatan tabbatarwa ba a ba su izinin cire kayan aikin, kuma dole ne a aiwatar da tabbatar da aikin auna bayan kowane gyare-gyare don guje wa kuskuren kayan aiki.

6.7 kamfanin ba zai dauki alhakin duk wani asarar da aka samu ta hanyar gyara na'urar ba tare da izinin kamfanin yayin amfani da na'ura ba.

6.8 kamfanin ba zai ɗauki alhakin duk sakamakon da aikin ya haifar ba daidai da ka'idoji da buƙatun littafin ba.

Abubuwan da aka bayar na SHANDONG DRICK INSTRUMENTS CO., LTD

Bayanin Kamfanin

Shandong Drick Instruments Co., Ltd, ya fi tsunduma cikin bincike da haɓakawa, masana'antu da siyar da kayan gwaji.

Kamfanin da aka kafa a 2004.

Ana amfani da samfurori a sassan binciken kimiyya, cibiyoyin bincike masu inganci, jami'o'i, marufi, takarda, bugu, roba da robobi, sunadarai, abinci, magunguna, masaku, da sauran masana'antu.

Drick yana mai da hankali ga haɓaka gwaninta da ginin ƙungiya, yana bin ra'ayin haɓaka ƙwarewar ƙwarewa, sadaukarwa.pragmatism, da ƙima.

Yin riko da ka'idar abokin ciniki, warware mafi gaggawa da bukatun abokan ciniki, da samar da mafita na farko ga abokan ciniki tare da samfurori masu inganci da fasaha na ci gaba.