DRK255-Kayan Gwajin Gwajin Kare Gumi

Takaitaccen Bayani:

Da farko, na gode da yawa don siyan DRK255 Hotplate ɗin mu, kafin shigarwa da amfani da shi, da fatan za a karanta wannan littafin a hankali, wanda zai iya taimaka muku wajen daidaita aikin da sauƙaƙe sakamakon gwajin daidai. Catalog l Bayanin 1.1 Takaitaccen Gabatarwa 1.2 Aikace-aikacen 1.3 Ayyukan kayan aiki 1.4 Amfani da yanayi 1.4.1 Yanayin zafin jiki da zafi 1.4.2 Buƙatun wutar lantarki 1.4.3 Babu kewaye da tushen girgizawa, da sauransu.

Da farko, na gode sosai don siyan muDRK255Plate mai Kula da gumi, kafin shigarwa da amfani, da fatan za a karanta wannan jagorar a hankali, wanda zai iya taimaka muku daidaita aikin da sauƙaƙe sakamakon gwajin daidai.

Katalogi

lDubawa

1.1 Takaitaccen Gabatarwa

1.2 Aikace-aikace

1.3 Ayyukan kayan aiki

1.4 Amfani da muhalli

1.4.1 Yanayin yanayi da zafi

1.4.2 Bukatun wutar lantarki

1.4.3 Babu kusa da tushen girgiza, da sauransu.

1.5 Ma'aunin fasaha

1.6 Gabatarwa Ka'ida

1.6.1 Ma'anar da naúrar juriya na thermal

1.6.2 Ma'anar da naúrar juriya danshi

1.7 Tsarin kayan aiki

1.8 Halayen kayan aiki

1.8.1 Kuskuren sake maimaitawa

1.8.2 Karamin tsari da ingantaccen mutunci

1.8.3 Nuni na ainihi na ƙimar "zazzabi da zafi".

1.8.4 Babban kwaikwaya tasirin gumi na fata

1.8.5 Multi-point calibration mai zaman kansa

1.8.6 Microclimate zafin jiki da zafi sun yi daidai da daidaitattun wuraren sarrafawa

lKafin Amfani

2.1 Karɓa da dubawa

2.2 Shigarwa

2.3 Kunna wutar lantarki kuma tabbatar

lAiki

3.1 Hanyoyin gwaji da ma'auni

3.2 Shiri kafin farawa

3.3 Gudun aikin juriya na thermal

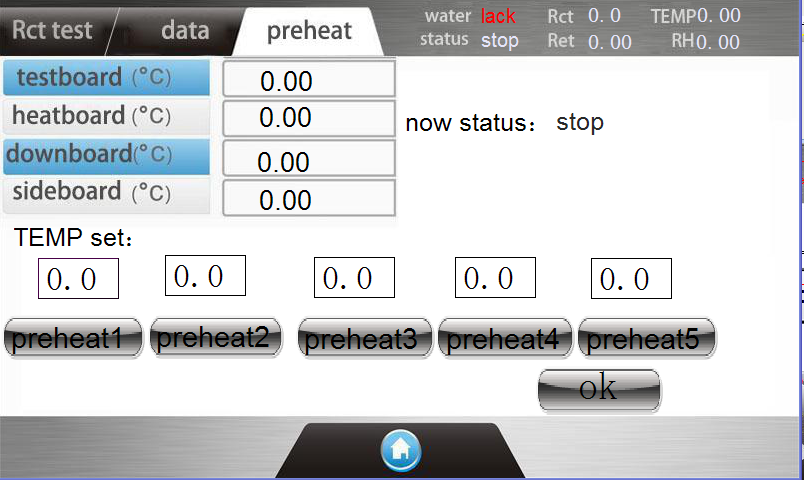

3.3.1 Injin preheating

3.3.2 Saitin juriya na thermal

3.3.3 Thermal juriya blank farantin gwajin

3.3.4 Gwajin juriya na thermal

3.3.5 Duba, bugu da share juriyar zafi

3.3.6 Ƙimar juriya na thermal

3.3.7 Thermal juriya m samfurori

3.4 Gudun aikin juriya na danshi

3.4.1 Na'urar preheating

3.4.2 Saitin juriya na danshi

3.4.3 Humidification da aikin cika ruwa

3.4.4 Gwajin juriya mai ɗanɗano

3.4.5 Gwajin juriya na danshi

3.4.6 Dubawa da buga juriya danshi

3.4.7 Daidaita juriya na danshi

3.4.8 Ƙwararren juriya mai amfani da samfurori

3.4.9 Canjin juriya na danshi da gwajin juriya na thermal

lSamfurin bukatun

4.1 Samfurin kula da zafi

4.2 Samfurin yawa da girma

4.3 Bukatun don samfurin jeri

lMuhimmancin juriya na thermal da danshi

5.1 Muhimmancin juriya na thermal

5.2 Muhimmancin juriyar danshi

lGoyon bayan sana'a

6.1 Gane kuskure

6.2 Kulawa

lMatsalolin gama gari

7.1 Matsalar lokacin ganowa

7.2 Matsalar girman samfurin

7.3 Ko saitin zafin jiki yana da alaƙa da ƙimar juriya na thermal

7.4 An gano matsalar fihirisa

7.5 Daidaita kayan aiki da matsalolin samfurin misali

l8. Shafi: Lokacin tunani na gwaji

Dubawa

1.1 Bayanin jagorar

Littafin yana ba da aikace-aikacen Hotplate na DRK255, ƙa'idodin gano asali da cikakkun bayanai ta amfani da hanyoyi, yana ba da alamun kayan aiki da jeri daidai, kuma yana bayyana wasu matsalolin gama gari da hanyoyin jiyya ko shawarwari.

1.2 Iyakar aikace-aikace

DRK255 Hotplate mai kariya na gumi ya dace da nau'ikan yadudduka daban-daban, gami da yadudduka na masana'antu, yadudduka marasa saƙa da sauran kayan lebur iri-iri.

1.3 Ayyukan kayan aiki

Wannan kayan aiki ne da ake amfani da shi don auna juriya na thermal (Rct) da juriya na danshi (Ret) na yadi (da sauran) kayan lebur. Ana amfani da wannan kayan aikin don saduwa da ka'idodin ISO 11092, ASTM F 1868 da GB/T11048-2008.

1.4 Amfani da muhalli

Ya kamata a sanya kayan aiki tare da ingantacciyar yanayin zafi da zafi, ko a cikin ɗaki mai kwandishan gabaɗaya. Tabbas, zai zama mafi kyau a cikin ɗakin zafin jiki na dindindin da zafi. Ya kamata a bar gefen hagu da dama na kayan aikin aƙalla 50cm don sa iska ta gudana cikin da fita cikin sauƙi.

1.4.1 Yanayin muhalli da zafi:

Yanayin yanayi: 10 ℃ zuwa 30 ℃; Dangantakar zafi: 30% zuwa 80%, wanda ke dacewa da kwanciyar hankali na zazzabi da zafi a cikin ɗakin microclimate.

1.4.2 Buƙatun wutar lantarki:

Dole ne kayan aikin ya kasance da ƙasa sosai!

AC220V± 10% 3300W 50Hz, matsakaicin ta halin yanzu shine 15A. Socket a wurin samar da wutar lantarki ya kamata ya iya jurewa fiye da 15A halin yanzu.

1.4.3Babu tushen jijjiga a kusa da shi, babu matsakaicin lalata, kuma babu ratsawar iska.

1.5 Ma'aunin Fasaha

1. Matsakaicin gwajin juriya na thermal: 0-2000 × 10-3(m2 •K/W)

Kuskuren maimaitawa bai wuce: ± 2.5% (ikon sarrafa masana'anta yana cikin ± 2.0%)

(Ma'aunin da ya dace yana cikin ± 7.0%)

Ƙaddamarwa: 0.1×10-3(m2 •K/W)

2. Gwajin juriya na danshi: 0-700 (m2 • Pa / W)

Kuskuren maimaitawa bai wuce: ± 2.5% (ikon sarrafa masana'anta yana cikin ± 2.0%)

(Ma'aunin da ya dace yana cikin ± 7.0%)

3. Zazzabi daidaita kewayon allon gwaji: 20-40 ℃

4. Gudun iskar da ke sama da saman samfurin: Daidaitaccen saitin 1m / s (daidaitacce)

5. Matsayin ɗagawa na dandamali (samfurin kauri): 0-70mm

6. Gwajin saitin lokaci: 0-9999s

7. Matsakaicin kula da zafin jiki: ± 0.1 ℃

8. Resolution na zafin jiki nuni: 0.1 ℃

9. Pre-zafi lokaci: 6-99

10. Girman samfurin: 350mm × 350mm

11. Girman allo: 200mm × 200mm

12. Girman Waje: 1050mm×1950mm×850mm (L×W×H)

13. Wutar lantarki: AC220V± 10% 3300W 50Hz

1.6 Gabatarwa Ka'ida

1.6.1 Ma'anar da naúrar juriya na thermal

Juriya na thermal: busasshen zafi yana gudana ta wurin ƙayyadadden yanki lokacin da yadin ya kasance a cikin madaidaicin yanayin zafi.

Ƙungiyar juriya ta thermal Rct tana cikin Kelvin kowace watt kowace murabba'in mita (m2· K/W).

Lokacin gano juriya na thermal, ana rufe samfurin akan allon gwajin dumama na lantarki, allon gwajin da allon kariya da ke kewaye da farantin ƙasa ana kiyaye su a daidai wannan yanayin zafin jiki (kamar 35 ℃) ta hanyar sarrafa dumama lantarki, da zafin jiki. firikwensin yana watsa bayanai zuwa tsarin sarrafawa don kula da yawan zafin jiki na yau da kullum, don haka za'a iya watsar da zafi na farantin samfurin kawai zuwa sama (a cikin jagorancin samfurin), kuma duk sauran kwatance sune isothermal, ba tare da musayar makamashi ba. A 15mm a saman saman saman tsakiyar samfurin, zazzabi mai kulawa shine 20 ° C, yanayin zafi shine 65%, kuma saurin iska a kwance shine 1m/s. Lokacin da yanayin gwajin ya tabbata, tsarin zai ƙayyade ƙarfin dumama da ake buƙata don allon gwajin don kula da yawan zafin jiki.

Matsakaicin juriya na thermal yana daidai da juriya na thermal na samfurin (15mm iska, farantin gwaji, samfurin) rage juriya na thermal na farantin komai (15mm iska, farantin gwaji).

Kayan aiki yana ƙididdigewa ta atomatik: juriya na zafi, ƙimar canja wurin zafi, ƙimar Clo da ƙimar adana zafi

Lura: (Saboda bayanan maimaitawa na kayan aiki yana da daidaituwa sosai, juriya na thermal na katako mara kyau kawai yana buƙatar yin sau ɗaya kowane watanni uku ko rabin shekara).

Thermal juriya: Rct: (m2K/W)

Tm ——gwajin zafin jiki

Ta ——gwajin zafin murfin

A —— yankin allon gwaji

Rct0——juriya mai zafi na allo

H —— gwajin wutar lantarki

△Hc — gyaran wutar lantarki

Matsakaicin canja wurin zafi: U = 1/Rct(W/m2· K)

Clo: CLO10.155 · ku

Yawan adana zafi: Q=Q1-Q2Q1×100%

Q1-Babu samfurin zafi mai zafi (W/℃)

Q2 - Tare da samfurin zafi mai zafi (W / ℃)

Lura:(Kimar Clo: a dakin da zazzabi na 21 ℃, dangi zafi ≤50%, iska 10cm/s (ba iska), mai gwajin yana zaune har yanzu, kuma basal metabolism shine 58.15 W / m2 (50kcal / m)2·h), jin dadi kuma kula da matsakaicin zafin jiki na saman jiki a 33 ℃, ƙimar suturar tufafin da aka sawa a wannan lokacin shine darajar 1 Clo (1 CLO = 0.155 ℃ · m).2/W)

1.6.2 Ma'anar da naúrar juriya danshi

Juriya mai danshi: zafin zafi na ƙanƙara ta wani yanki a ƙarƙashin yanayin tsayayyen tururin matsa lamba na ruwa.

Ƙungiyar juriyar danshi Ret tana cikin Pascal kowace watt kowace murabba'in mita (m2·Pa/W).

Farantin gwaji da farantin kariyar duka faranti ne na musamman na ƙarfe, waɗanda aka lulluɓe da fim na bakin ciki (wanda ke iya mamaye tururin ruwa kawai amma ba ruwan ruwa ba). A ƙarƙashin dumama wutar lantarki, yawan zafin jiki na distilled ruwa da tsarin samar da ruwa ke bayarwa ya tashi zuwa ƙimar da aka saita (kamar 35 ℃). Gwajin gwajin da allon kariya da ke kewaye da farantin da ke ƙasa duk ana kiyaye su a yanayin zafin jiki ɗaya (kamar 35 ° C) ta hanyar sarrafa dumama wutar lantarki, kuma firikwensin zafin jiki yana watsa bayanan zuwa tsarin sarrafawa don kiyaye yanayin zafi akai-akai. Sabili da haka, makamashin zafi mai tururi na ruwa na samfurin samfurin zai iya zama sama kawai (a cikin jagorancin samfurin). Babu tururin ruwa da musayar zafi a wasu wurare,

allon gwajin da kewayen allon kariya da farantin kasa duk ana kiyaye su a daidai wannan yanayin da aka saita (kamar 35 ° C) ta hanyar dumama wutar lantarki, kuma firikwensin zafin jiki yana watsa bayanan zuwa tsarin sarrafawa don kiyaye yanayin zafi akai-akai. Ƙarfin zafi na tururin ruwa na farantin samfurin za a iya bazuwa sama kawai (a cikin kwatancen samfurin). Babu musanyawar makamashin tururin ruwa a wasu wurare. Ana sarrafa zafin jiki a 15mm sama da samfurin a 35 ℃, yanayin zafi shine 40%, kuma saurin iska a kwance shine 1m/s. Ƙananan farfajiyar fim ɗin yana da madaidaicin ruwa na 5620 Pa a 35 ℃, kuma saman saman samfurin yana da matsa lamba na ruwa na 2250 Pa a 35 ℃ da zafi na dangi na 40%. Bayan yanayin gwajin ya tabbata, tsarin zai ƙayyade wutar lantarki ta atomatik da ake buƙata don allon gwajin don kula da yawan zafin jiki.

Ƙimar juriya na danshi daidai yake da juriya na samfurin (15mm iska, gwajin gwaji, samfurin) rage juriya na danshi na katako (15mm iska, gwajin gwaji).

Na'urar tana ƙididdigewa ta atomatik: juriya da ɗanɗano, ma'anar raɗaɗin danshi, da ƙarancin danshi.

Lura: (Saboda bayanan maimaitawa na kayan aiki yana da daidaituwa sosai, juriya na thermal na katako mara kyau kawai yana buƙatar yin sau ɗaya kowane watanni uku ko rabin shekara).

Juriya da danshi: Ret Pm--Cikakken tururi

Pa——Matsayin tururi na ɗakin yanayi

H—— Gwajin wutar lantarki

△Shi — Gyara adadin wutar lantarki na hukumar gwaji

Ma'anar dacewar ɗanshi: imt=s*Rct/RdaS- 60 pa/k

Ƙwararren danshi: Wd= 1 / Ret* φTmg/ (m2*h*pa)

φTm-Latent zafi na saman tururin ruwa, lokacinTm da 35℃时, φTm= 0.627 W*h/g

1.7 Tsarin kayan aiki

Kayan aiki ya ƙunshi sassa uku: babban injin, tsarin microclimate, nuni da sarrafawa.

1.7.1Babban jikin yana sanye da farantin samfurin, farantin kariya, da farantin ƙasa. Kuma kowane farantin dumama yana rabu da wani abu mai hana zafi don tabbatar da cewa ba za a canja wurin zafi tsakanin juna ba. Don kare samfurin daga iska mai kewaye, an shigar da murfin microclimate. Akwai kofa ta gilashin kwayoyin halitta a saman, kuma an shigar da firikwensin zafin jiki da zafi na dakin gwaji akan murfin.

1.7.2 Nuni da tsarin rigakafi

Kayan aiki yana ɗaukar allon taɓawa na weinview touch allon hadedde, kuma yana sarrafa tsarin microclimate da mai watsa shiri na gwaji don yin aiki da tsayawa ta taɓa maɓallan da suka dace akan allon nuni, bayanan sarrafawar shigarwa, da bayanan gwajin fitarwa na tsarin gwaji da sakamako.

1.8 Halayen kayan aiki

1.8.1 Kuskuren sake maimaitawa

Babban ɓangaren DRK255 tsarin kula da dumama na'ura ce ta musamman da aka bincika kuma ta haɓaka. A ka'ida, yana kawar da rashin zaman lafiyar sakamakon gwajin da ya haifar da rashin ƙarfi na thermal. Wannan fasaha ta sa kuskuren gwajin maimaitawa yayi ƙasa da ƙa'idodi masu dacewa a gida da waje. Yawancin kayan aikin gwajin "canja wurin zafi" suna da kuskuren maimaitawa kusan ± 5%, kuma kamfaninmu ya kai ± 2%. Ana iya cewa ta warware matsalar duniya na dogon lokaci na manyan kurakurai masu maimaitawa a cikin kayan aikin zafin jiki kuma ya kai matakin ci gaba na duniya. .

1.8.2 Karamin tsari da ingantaccen mutunci

DRK255 na'ura ce da ke haɗa mai gida da microclimate. Ana iya amfani da shi da kansa ba tare da kowane na'urori na waje ba. Yana dacewa da yanayi kuma an haɓaka shi musamman don rage yanayin amfani.

1.8.3 Nuni na ainihi na ƙimar "zazzabi da zafi".

Bayan samfurin yana preheated zuwa ƙarshe, za a iya nuna tsarin daidaita darajar "zafin zafi da juriya na zafi" gaba ɗaya a ainihin lokacin. Wannan yana magance matsalar na dogon lokaci don gwajin juriya na zafi da danshi da rashin iya fahimtar dukkanin tsari.

1.8.4 Babban kwaikwaya tasirin gumi na fata

Kayan aiki yana da babban simulation na fata na mutum (boye) tasirin gumi, wanda ya bambanta da allon gwaji tare da ƙananan ƙananan ramuka. Yana gamsar da daidaitaccen tururin tururin ruwa a ko'ina a kan allon gwaji, kuma ingantaccen wurin gwajin daidai ne, don haka ma'aunin "juriya mai danshi" ya fi kusa da ƙimar gaske.

1.8.5 Multi-point calibration mai zaman kansa

Saboda ɗimbin kewayon gwajin juriya na zafi da danshi, daidaitawa mai zaman kanta mai ma'ana da yawa na iya inganta ingantaccen kuskuren da rashin daidaituwa ya haifar da tabbatar da daidaiton gwajin.

1.8.6 Microclimate zafin jiki da zafi sun yi daidai da daidaitattun wuraren sarrafawa

Idan aka kwatanta da kayan aiki iri ɗaya, ɗaukar yanayin yanayin zafi da zafi daidai da daidaitaccen wurin sarrafawa ya fi dacewa da "madaidaicin hanyar", kuma abubuwan da ake buƙata don sarrafa microclimate sun fi girma.

Kafin Amfani

Bayanin abubuwan da ke cikin wannan sashe ya haɗa da taƙaitawar farawa mai sauri don taimaka muku fahimtar sauri. Wannan zai jagorance ku ta hanyar saitin, daidaitawa da aikin asali na kayan aiki. Ana ba da shawarar ku fara nazarin wannan ɓangaren bayan bincika abubuwan da suka gabata.

2.1 Karɓa da dubawa

Bude akwatin kuma fitar da injin gaba daya don bincika lalacewar bayyane.

Ƙididdige bisa ga lissafin tattarawa, umarnin aiki da na'urorin haɗi.

2.2 Shigarwa

2.2.1Daidaita ƙafafu huɗu zuwa tsakiyar ginanniyar kumfa a kwance don tabbatar da matakin allon gwajin.

2.2.2 Waya

Haɗa ƙarshen kebul ɗin kwamfuta ɗaya zuwa soket ɗin kayan aikin kwamfuta da ƙarshen ɗaya zuwa kwamfutar (na zaɓi)

2.3 Kunna wutar lantarki kuma tabbatar

Kunna wuta kuma duba ko nunin na al'ada ne.

Aiki

3.1 Hanyoyin gwaji da ma'auni

ISO 11092, ASTM F 1868, GB/T11048-2008

3.2 Shiri kafin farawa

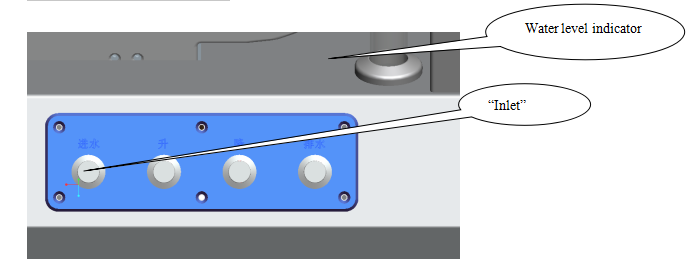

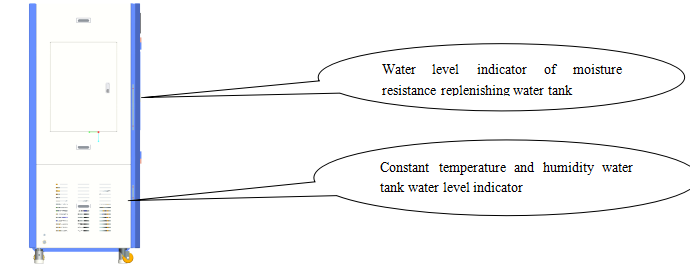

3.2.1Kafin fara na'ura, duba ko akwai isasshen ruwa a cikin alamar matakin ruwa na yawan zafin jiki da tankin ruwan zafi. Idan babu ruwa, da fatan za a ƙara ruwa tukuna. In ba haka ba, ko da an kunna shi, yawan zafin jiki da zafi ba zai yi aiki ba. Yadda za a ƙara ruwa: Buɗe ƙofar gaba, kwance murfin bakin karfe a gefen hagu, ɗauki mazugi na kayan haɗi, kuma zuba ruwan ma'adinai (ana ba da shawarar ruwa mai narkewa) don samar da daidaitawar yanayin zafi. Zuba ruwan zuwa tsakanin layin alamar matakin ruwa.

3.2.2Da fatan za a tabbatar ko akwai ruwa a cikin alamar matakin ruwa na juriya mai juriya da ke cika tankin ruwa a gefen hagu na sama, sannan a ba da gwajin juriyar danshi. Hanyar aiki: koma zuwa abu 3.4.3 [Humidification da aikin sake cikawa da aikin sanya fim ɗin gwaji]Lura:Dole ne a cika wannan tankin ruwa da ruwa mai narkewa.

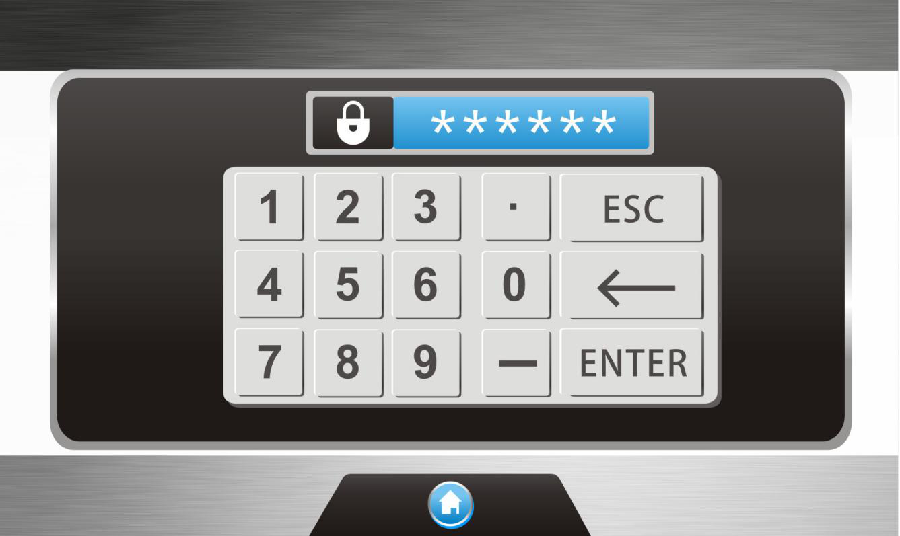

3.2.3 Gabatarwa shafi da saitin siga

Matsakaicin zafin jiki da yanayin zafi; bayan kun kunna wuta, ana nuna mahaɗin shiga mai zuwa:

Danna maɓallin "Login" don shigar da kalmar wucewa

Bayan shigar da daidai, zai nuna:

Babban dubawa yana da abubuwa 4: gwaji, saita, daidai da bayanai.

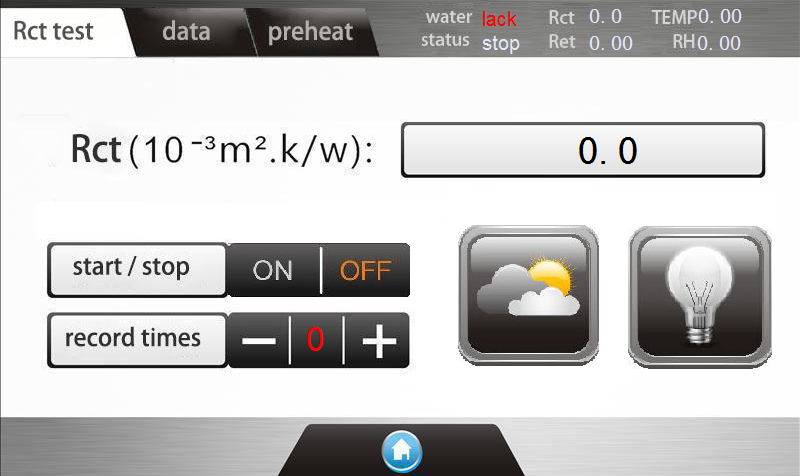

Gwaji: Ana amfani da ƙirar gwajin don shigar da gwajin juriya na zafi ko danshi, da kunna ko kashe tsarin firiji da haske.

Latsa maɓallin kula da firiji a cikin hoto 305-1 don kunna ko kashe firiji kuma fara tsarin zafin jiki akai-akai da yanayin zafi da sarrafa hasken wuta; Hoto 305-2 kayan aiki bayanan aiki na ainihi; Hoto na 305-3 shine aikin zafin injin sanyi;

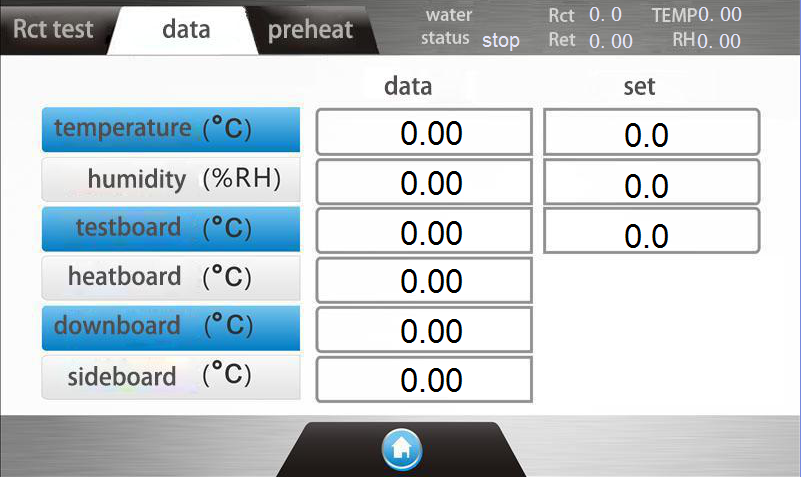

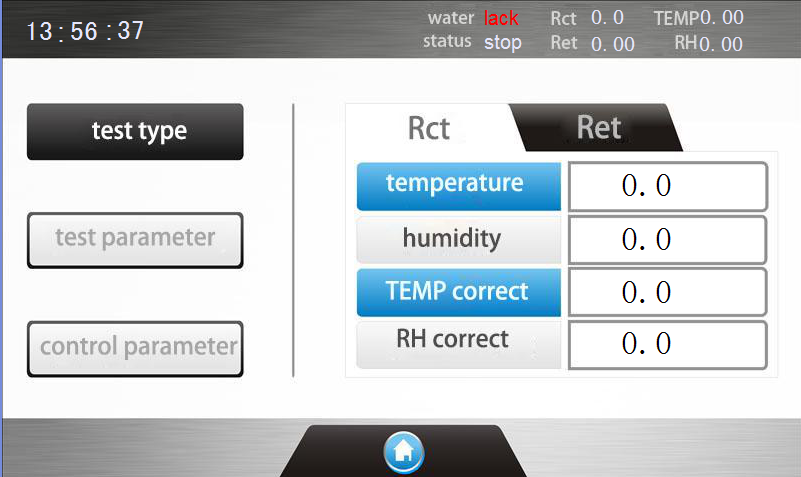

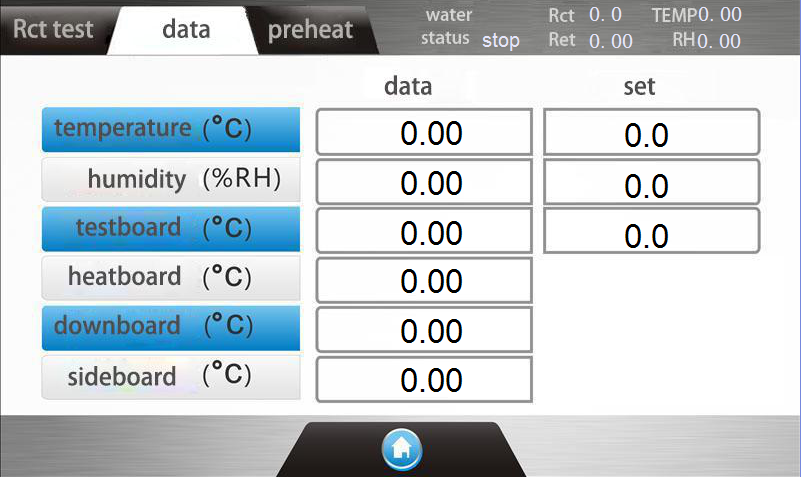

Saita: ana amfani dashi don saita sigogin gwaji da yanayin yanayin yanayin zafi da zafi

Saitunan ma'aunin zafi da zafi:

Lokacin zaɓar juriya na thermal, tsarin zai saita yanayin zafi na microclimate ta atomatik zuwa 20 ℃ da zafi zuwa 65%;

Lokacin zabar juriya na danshi, tsarin zai saita zafin jiki na microclimate ta atomatik zuwa 35 ° C da zafi zuwa 40%;

Masu amfani kuma za su iya saita wasu sigogin zafin jiki da zafi bisa ga ainihin yanayi.

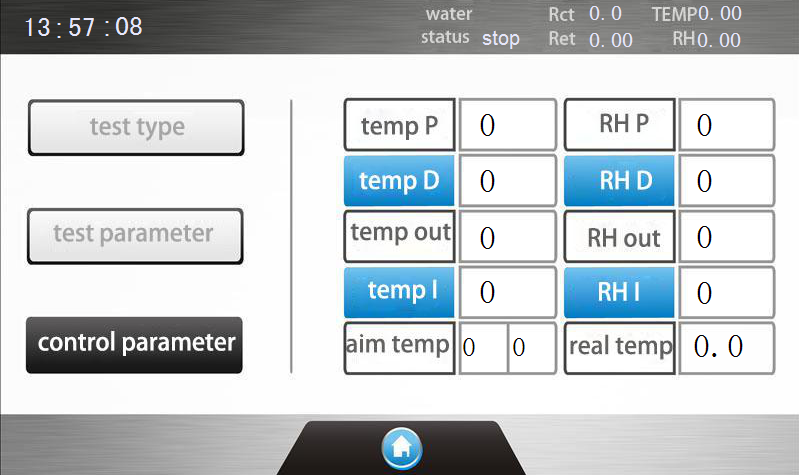

Saitunan sigar sarrafa zafi da zafi a cikin sito:

Saitin saiti na yanayin zafi da zafi, an saita wannan ɓangaren siga kafin barin masana'anta, mai amfani gabaɗaya baya buƙatar saita wannan abu, idan ya cancanta, ƙwararrun masana'anta na iya saita shi.

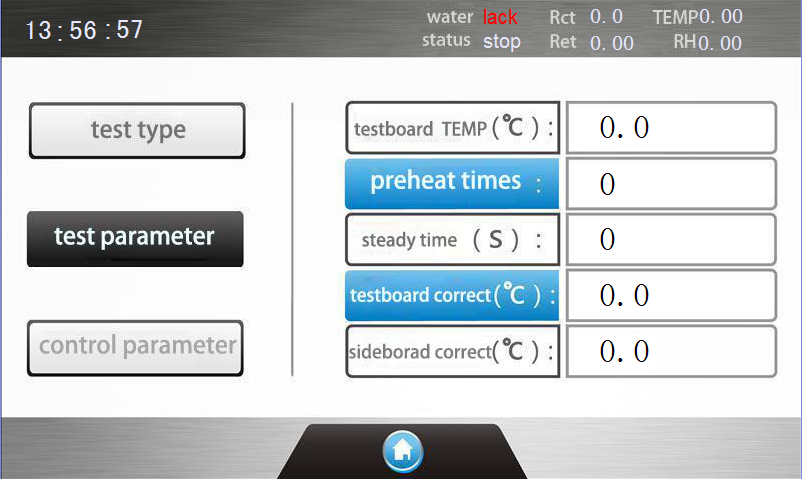

Saitin sigar juriya na thermal da danshi:

Bisa ga ma'auni, an saita zafin jiki na hukumar gwajin zuwa 35 ℃, da preheating sake zagayowar ne kullum 6 sau, da kuma gwajin lokaci ne 600 seconds (wannan shi ne na al'ada tsoho saitin, kamar na farko gwajin na samfurin ko gwajin lokacin gwaji mai kauri).

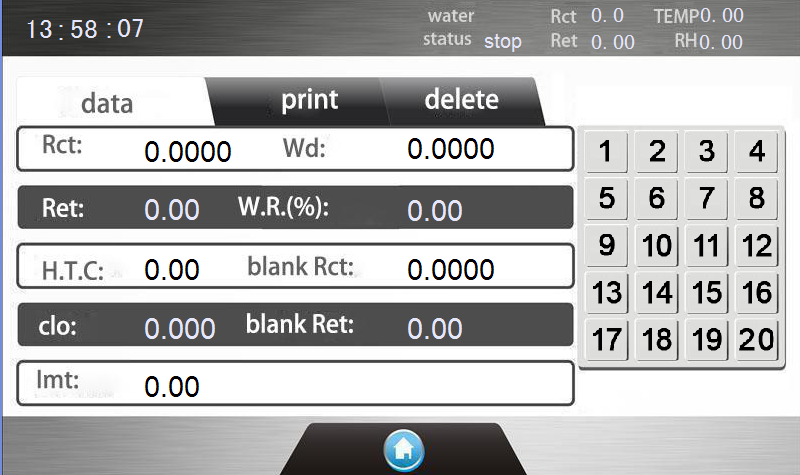

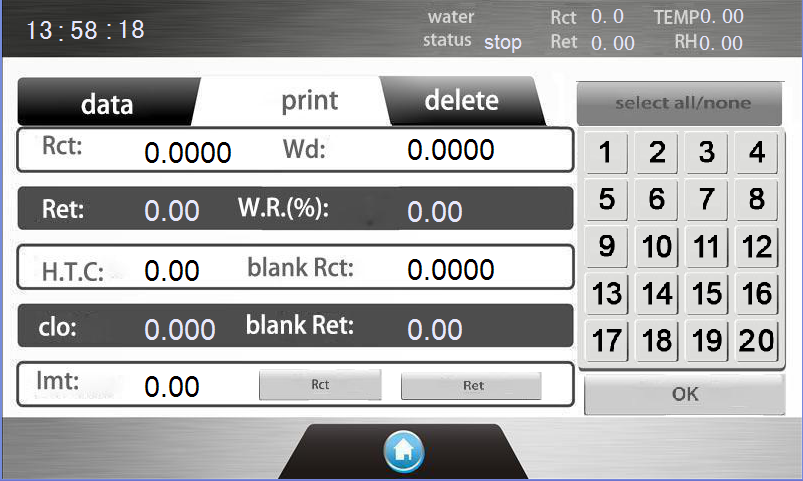

Buga: ana amfani dashi don tambaya da buga bayanai, da share bayanan

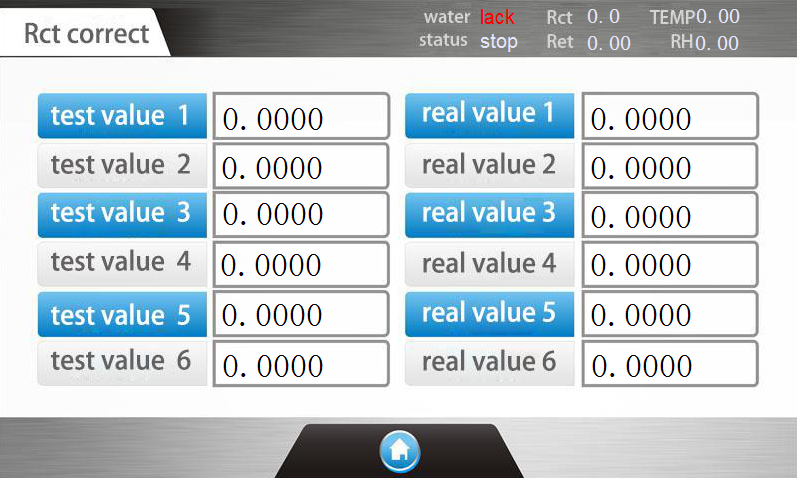

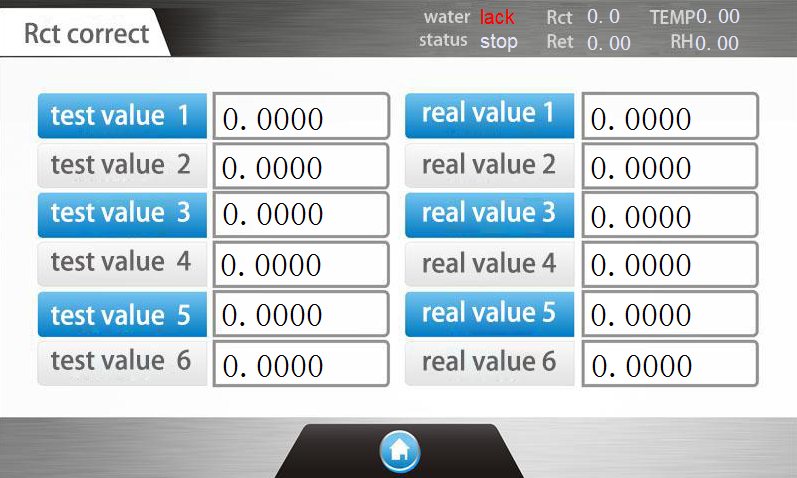

Rct Correct: ana amfani dashi don daidaita bayanan juriya na thermal

3.3 Gudun aikin juriya na thermal

Da farko duba ko allon gwajin ya bushe gaba daya (idan rigar, da fatan za a duba aikin 3.4.9).

3.3.1 Injin preheating

Bayan kunna wutar lantarki, duk injin yana buƙatar preheated na kimanin mintuna 45, yayin da aka sanya masana'anta mai matsakaicin kauri akan farantin da aka lalata. Lokacin da farantin gwajin ya kai 35 ° C, ana fitar da masana'anta, sannan ana lura da zazzabi na farantin dumama da farantin ƙasa ya kai kusan 35.2 don kammala sanyaya. Bayan da injin ɗin ya riga ya ɗora, ana iya sanya samfurin gwajin (ko daidaitaccen samfurin) a cikin benci na gwaji.

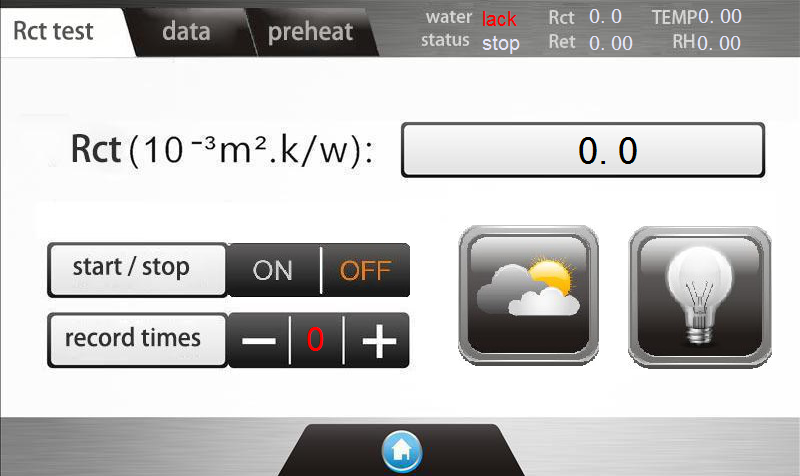

3.3.2 Saitin juriya na thermal Dubi Hoto 309

Saita sigogi a cikin saitin sigina kuma danna "Test" don shigar da gwajin "thermal resistanc".

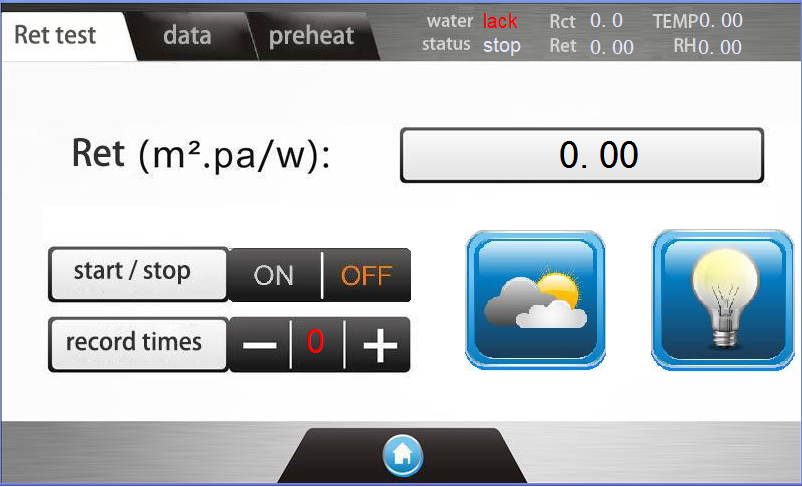

Gwajin gwajin yana nunawa kamar yadda aka nuna a hoto 314:

3.3.3 Thermal juriya blank farantin gwajin

Kafin gwaji, dole ne a sami “babu samfurin juriya na thermal” - juriyar zafin farantin blank.

Matsakaicin zafin jiki na farantin blank shine juriya na thermal na kayan aiki da kanta ba tare da samfurin ba.

A cikin "aiki na juriya na thermal", zaɓi "Lokacin gwaji" zuwa 0 kuma latsa "fara" don yin "gwajin faranti mara kyau". Jerin gwaji: preheat-stable-test-test-stop (sami juriya na thermal na allon babu kuma adana shi ta atomatik)

Lura:Ana ba da shawarar yin "juriya mai zafi na blank" sau ɗaya a cikin Maris zuwa Yuni. Saboda kuskuren maimaitawa na gwajin allo mara kyau na wannan kayan aiki kadan ne, ba lallai ba ne a fara juriyar zafin jiki mara kyau kowace rana.

3.3.4 Gwajin juriya na thermal

A cikin "aikin juriya na thermal" dubawa

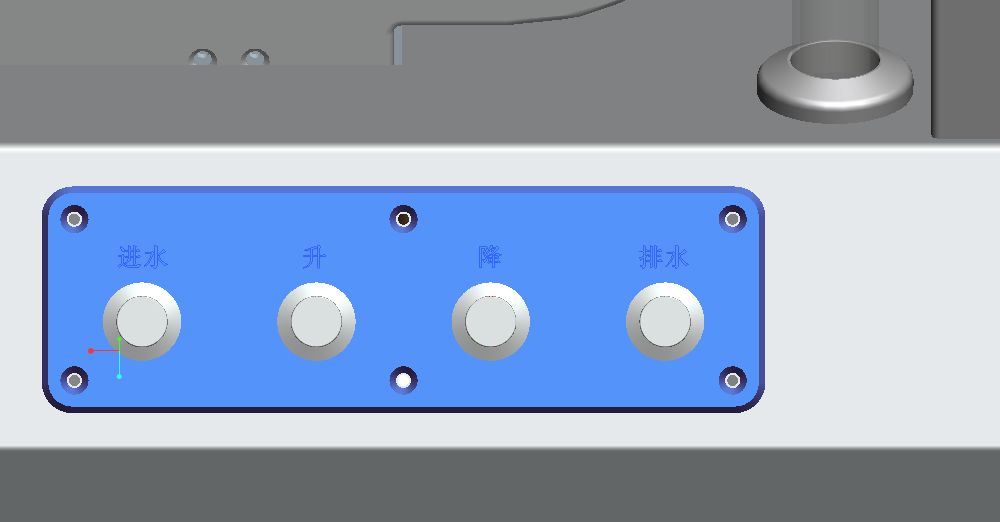

Bayan saduwa da buƙatun 3.3.1, sanya samfurin a saman farantin da aka lalata, daidaita maɓallin "sama da ƙasa" a gaban benci na gwaji a cikin ɗakin gwaji, kuma rufe bangarorin hudu na mariƙin ƙarfe, lokacin da mariƙin karfe yana daidai a cikin matsayi na kwance. Sanya murfin plexiglass, rufe ƙofar kayan aiki, danna maɓallin "fara", kuma kayan aikin zai gudana ta atomatik.

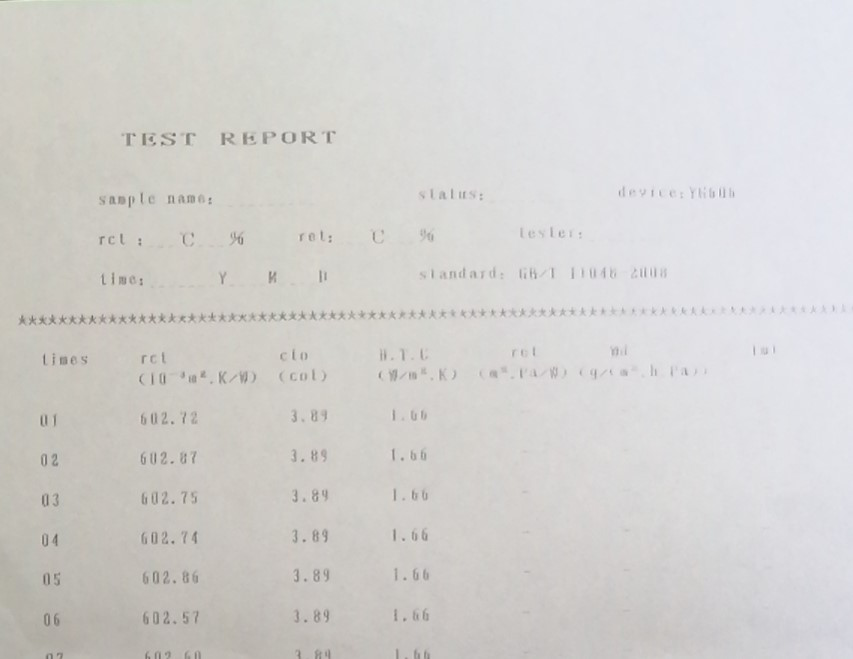

Jeri mai gudana: preheat-stable-test- test-stop, nuna juriya na thermal na farko da sauran alamomi.

Lura:Bayan nuna “barga”, idan mai amfani yana tunanin cewa bayanan gaskiya ne kuma baya buƙatar ci gaba da gwaji, zaku iya danna maɓallin “tsayawa”, kuma kayan aikin zai riƙe ƙimar juriya na thermal da aka nuna azaman sakamakon gwajin.

Canja samfurin, danna 2 don "lokutan rikodi" don gwada samfurin na biyu, da sauransu. Ana iya buga rahoton gwajin bayan gwaje-gwaje 3 bisa ga ma'aunin hanya.

3.3.5 Duba, bugu da share juriyar zafi

Danna "Buga" don nuna mahallin "Data Query and Print", kamar yadda aka nuna a hoto 317

Danna maɓallin "Ok", kuma kayan aiki za su buga rahoton gwajin juriya ta atomatik, kamar yadda aka nuna a hoto 318.

Canja zuwa wurin sharewa, zaɓi rikodin da za a goge, sannan danna “Ok”, za a goge bayanan gwajin da aka zaɓa a halin yanzu, kuma za a maye gurbinsa da bayanan gwaji na gaba.

3.3.6 Ƙimar juriya na thermal

Ana ba da shawarar yin hakan lokacin da sabon na'ura, ko aka daidaita shi sau ɗaya a kowane watanni shida, da lokacin da ƙimar ta kasance mara kyau.

3.3.6.1 Sanya samfurin ma'aunin soso (misali na yau da kullun tare da ƙimar juriya na ƙima) da aka bayar a cikin kayan haɗin kayan aiki a cikin benci na gwaji

3.3.6.2 Bincika sakamakon gwajin da daidaitattun sakamakon ƙarƙashin shafin daidaita yanayin juriya don tabbatar da cewa duk bayanan ba su da sifili.

3.3.6.3 A cikin gwajin juriya na thermal, zaɓi "lokacin rikodin 1" kuma danna maɓallin "Fara".Lura:Hakanan kuna buƙatar saduwa da jumlar 3.3.1 kafin danna maɓallin “Fara”.

Yayin gwajin juriya na thermal, kusurwar dama ta sama na wannan shafin ta fara nuna "Preheat", "Stable", "Gwaji", "Tsaya", da "Lokacin rikodi 1", karshen gwajin.

3.3.6.4 Sa'an nan kuma saka a cikin soso misali samfurori na sauran kauri, kuma auna sakamakon gwajin "lokacin rikodin 12" da "lokacin rikodin 3" kamar yadda yake cikin 3.3.6.1 zuwa 3.3.6.3.

3.3.6.5 Shigar da ma'aunin juriya na thermal na samfuran soso na kauri daban-daban a cikin abubuwan da suka dace na "Sakamakon Gwaji", kuma shigar da "ma'auni na bayanai" akan samfuran daidaitattun daidaitattun abubuwa a cikin abubuwan da suka dace na "Standard Result" .

Hakanan mai amfani zai iya zaɓar ma'aunin kauri ɗaya ko biyu kawai don daidaitawa, da shigar da "0" don sauran. Lura: A cikin mahallin "Thermal Resistance Calibration", shigar da daidaitattun bayanan samfurin soso daga ƙanana zuwa babba bisa tsarin sakamakon gwaji 1, 2, 3, da daidaitattun sakamakon 1, 2, 3.

Latsa "Koma" don fita da dubawa kuma daidaitawa ya cika.

Lura: Kar a canza bayanai a cikin daidaitawar juriyar zafin zafi cikin sauƙi a lokuta na yau da kullun. Zai fi kyau a ajiye kwafi a wasu wurare don gujewa rasa bayanan daidaitawa.

Hakanan mai amfani zai iya zaɓar ma'aunin kauri ɗaya ko biyu kawai don daidaitawa, da shigar da "0" na sauran.Lura:A cikin mahallin “Thermal Resistance Calibration”, shigar da daidaitattun bayanan samfurin soso daga ƙanana zuwa babba bisa tsarin sakamakon gwaji 1, 2, 3, da daidaitattun sakamakon 1, 2, 3.

Latsa "Koma" don fita da dubawa kuma daidaitawa ya cika.

Lura:Kar a canza bayanai a cikin daidaitawar juriyar zafi cikin sauƙi a lokutan talakawa. Zai fi kyau a ajiye kwafi a wasu wurare don gujewa rasa bayanan daidaitawa.

3.3.7 Thermal juriya m samfurori

Wannan kayan aikin ba'a iyakance ga gano juriya na thermal na yadudduka ba, kuma ana iya amfani dashi akan gano juriya na thermal na kayan faranti daban-daban.

3.4 Gudun aikin juriya na danshi

3.4.1 Na'urar preheating

Bayan kunna wutar, duk injin yana buƙatar preheated na kusan mintuna 60. A cikin lokacin, ya kamata a tabbatar da cewa an kammala aikin humidification na 3.4.3 da gyaran ruwa da aikin sanya fim ɗin gwaji. Saka wani matsakaici-kauri masana'anta a kan porous farantin, da kuma fitar da masana'anta a lokacin da gwajin farantin ya kai 35 ℃ , Sa'an nan kuma lura da dumama farantin zazzabi da kasa farantin zazzabi zuwa game da 35.2, kammala sanyi inji preheating, za ka iya sa gwajin samfurin a cikin gwajin benci.

3.4.2Danshisaitin juriya

Danna maɓallin "Saituna", kuma danna "Zafi da Humidity Resistance Parameter Setting" don nuna alamar 309.

3.4.3 Humidification da aikin cika ruwa

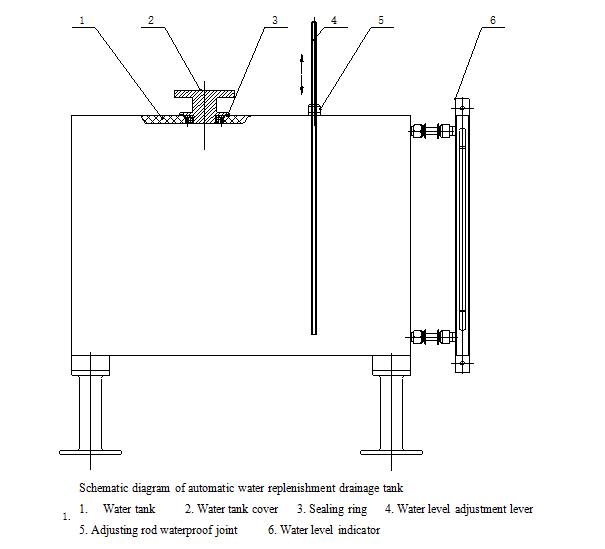

Bincika ko akwai ruwa a cikin tanki mai cike da ruwa ta atomatik. Idan babu ruwa, bude karamar kofa a gefen hagu na kayan aiki, cire murfin tankin ruwa 2, sa'an nan kuma saka sandar alamar matakin ruwa 4 a cikin kasan tankin ruwa kuma ƙara madaidaicin sandar mai hana ruwa 5, sannan a ɗauka. mazurari daga kayan haɗi, Sa'an nan kuma zubadistilledruwa a cikin bakin tanki na ruwa, sanya matakin ruwa tsakanin jajayen layuka na matakin ruwa mai nuna alama 6, sannan ku matsa murfin tankin ruwa.

Danna maballin "Mashiga Ruwa" da aka nuna a hoto na 323, sassauta mahaɗin mai hana ruwa na sandar daidaitawa kaɗan, sannan a hankali ɗaga sandar daidaita matakin ruwa. Ruwan da ke cikin tanki mai cikawa zai gudana ta atomatik cikin jikin gwajin. Kula da alamar matakin ruwa a gefen dama na benci na gwaji kuma gwada Idan ka taɓa saman farantin latsa da hannunka, lokacin da danshi ya fito, za ka iya dakatar da lever daidaita matakin ruwa don ja sama, kuma ƙara ƙara mai haɗin ruwa mai hana ruwa. .

Gwajin Sanya Fim: Ɗauki fim ɗin gwaji daga abin da aka makala, yayyage fim ɗin kariya, kuma yi amfani da na roba don gwaji. Yada shi a saman farantin porous. Ɗauki shingen auduga a cikin abin da aka makala don santsin fim ɗin da kuma santsin fim ɗin. Cire kumfa na iska a tsakanin faranti, sannan ɗauki ɗigon roba daga abin da aka makala, kuma gyara fim ɗin a jikin gwajin a cikin kewayawa.

3.4.4 Gwajin juriya mai ɗanɗano

Kafin na'urar ta gano samfurin, dole ne a sami "babu samfurin juriya na danshi" - juriyar rigar rigar.

Rashin juriyar danshi na faranti mara kyau yana nufin juriya na kayan aiki da kanta lokacin da fim kawai.

Zaɓi "Lokacin rikodi 0" kuma latsa "Fara" don yin gwajin "juriyar ɗanshi na allo".

Tsarin gwajin juriya na danshi: preheat-stable-test-test (samu juriyar danshi na allon komai kuma adana shi ta atomatik)

3.4.5 Gwajin juriya na danshi

A cikin yanayin aikin juriya na zafi (za'a iya aiwatar da shi bayan zazzabi na faranti uku ya kai matakin 3.4.1)

Zaɓi 1 don lokacin rikodin (watau samfurin 1).

Bayan kayan aiki ya cika buƙatun 3.4.1, sanya samfurin gwajin a saman saman fim ɗin, danna maɓallin "sama, ƙasa", kuma rufe bangarorin huɗu na ƙusar ƙarfe. Lokacin da ƙuƙƙarfan ƙarfe yana cikin matsayi a kwance, sa'an nan kuma sanya murfin plexiglass. Rufe ƙofar kayan aiki kuma danna maɓallin "Fara". Kayan aikin zai yi aiki ta atomatik. Jeri mai gudana shine: Dumu-dumu-kwanciyar hankali-tasha gwaji, da nuna juriya na farko da sauran alamomi.

Canza samfurin; latsa 2 don lokacin rikodin don gwada samfurin na biyu, hanyar ita ce daidai da na sama, da sauransu. Ana iya buga rahoton gwajin juriya da danshi bayan gwaje-gwaje 3 bisa ga ma'aunin hanya.

3.4.6 Dubawa da buga juriya danshi

Ana buƙatar daidaita juriya da danshi. Matakan sun yi kama da yanayin juriya na thermal.

3.4.7 Tsare-tsare masu amfani da samfurori

Wannan kayan aikin ba'a iyakance ga gano juriyar danshi na yadudduka ba, kuma ya dace da gano juriya da danshi na kayan faranti daban-daban, amma ba shi da ma'ana don gano juriyar danshin abubuwan da ba su da ƙarfi, saboda ƙimar juriyar danshin ba ta da iyaka.

3.4.8Juyin juriya na danshi da gwajin juriya na thermal

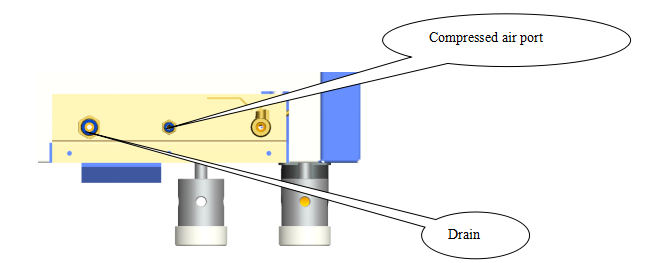

A gefen hagu na kayan aikin, kamar yadda aka nuna a hoto na 327, haɗa iska mai matsewa, sanya kwanon ruwa a ƙarƙashin magudanar ruwa, sannan danna maɓallin "Drain" a cikin ɗakin gwaji kamar yadda aka nuna a hoto 317, gabaɗaya danna 6 Game da 8 sau (lokaci daya bayan jin "danna"), ruwan za'a sauke ta atomatik, sannan saita zafin jiki na allon gwajin zuwa 40 ℃, sannan a yi aiki na awa 1 (bayan haka, idan allon gwajin da kariyar. jirgi har yanzu Idan akwai danshi, za a iya tsawaita lokacin da ya dace). Lokacin yin wannan aikin, kada a sami samfurin ko fim ɗin gwajin juriya a saman gwajin.

lMatse tashar jirgin sama

4.1 Samfurin kula da zafi: samfuran da samfuran gwaji yakamata a sanya su ƙarƙashin ƙayyadadden ƙayyadaddun yanayin yanayi don sarrafa zafi na awanni 24.

4.2 Samfurin yawa da girman: Ɗauki samfurori guda uku don kowane samfurin, girman samfurin shine 35 × 35cm, kuma samfurin ya kamata ya zama lebur kuma ba tare da wrinkles ba.

4.3 Abubuwan da ake buƙata don samfurin samfurin: An shimfiɗa gefen gaba na samfurin a kan allon gwajin, kuma an rufe dukkan sassan allon gwajin.

lMuhimmancin juriya na thermal da danshi

5.1Juriya na thermal shine halayyar yanayin canjin zafi na kayan aiki. Yana ɗaya daga cikin mafi mahimmancin alamomi don gwajin yadudduka. Saboda ayyuka uku na asali na tufafi (kariya mai dumi, kariyar jiki da kuma bayyanar da kai), abu mafi mahimmanci shine dumi. Idan babu sutura a yau Kariyar ɗan adam ba zai iya rayuwa ba. Abu na biyu, yankuna da yanayi daban-daban suna da buƙatun thermal daban-daban. Juriya na thermal zai iya ba da tushe ga mutane don zaɓar irin nau'in masana'anta, wanda ke nuna mahimmancin gano juriya na thermal.

5.2Juriya na danshi alama ce da ke nuna ikon kayan don watsa danshi. Tare da ingantuwar yanayin rayuwar mutane, ana gabatar da buƙatu masu girma don sanya kwanciyar hankali, saboda babba zai ratsa fata ko da babu gumi (gami da gumi) a kowace rana. 70 g/rana* mutum. Sa'an nan mafi yawan waɗannan danshi yana buƙatar yaduwa ta hanyar tufafi. Sai kawai lokacin da ikon kayan tufafi don watsa danshi ya wuce wannan darajar mutane za su iya jin dadi. Saboda wannan dalili, yana da mahimmanci don gano juriya na danshi.

lGoyon bayan sana'a

6.1 Gane kuskure

A, Babu nuni akan allon taya

- Duba ko wutar tana kunne

- Bincika ko an haɗa ƙarfin nunin

- Bincika ko an haɗa ƙarfin nunin

B, Zazzaɓi na dindindin da zafi ba zai iya gudana ba

- Matsayin ruwa a cikin ƙirar taya rawaya ne, da fatan za a ƙara ruwa

- Bincika ko layin haɗin tsakanin allon sarrafawa da allon tuƙi yana da alaƙa da kyau

- Bincika ko matsi na compressor na firiji ya fi girma ko ƙasa da matsin da aka saita

C, zafin jiki na yau da kullun da aikin zafi, ƙarancin zafin ɗakin gwaji

- Bincika ko za'a iya dumama bututun iska mai dumama;

- Duba ƙaƙƙarfan gudun ba da sanda na jihar da ke tuƙi bututun dumama iska.

D、 Yanayin zafi da aikin zafi, ƙarancin zafi a ɗakin gwaji

- Bincika ko za a iya dumama bututun tankin ruwa kullum

- Bincika ƙaƙƙarfan gudun ba da sanda na jihar wanda ke tafiyar da bututun dumama na tankin ruwa

E, Babu nunin zafin jiki akan allon gwaji, allon dumama ko kasa

1. Ko ma'aunin zafin jiki ya ƙone

2. Alamar haɗin haɗin ba ta da kyau, sake shigar da shi.

F. Allon gwaji, allon dumama ko farantin ƙasa ba zai iya yin zafi ko zafi a hankali ba

1. Bincika ko kayan wutan lantarki guda uku ana ba su wuta akai-akai;

2. Bincika da'irar sarrafawa na hita don ganin idan akwai mummuna lamba tare da filogi kai tsaye.

6.2 Kulawa

A. Kada ku yi karo da sassa daban-daban yayin sufuri, shigarwa, daidaitawa da amfani da kayan aiki don kauce wa lalacewar injiniya da tasiri sakamakon gwajin.

B. Ƙungiyar kula da kayan aiki shine crystal na ruwa da allon taɓawa, waɗanda ke da sauƙin lalacewa. Kada ku yi amfani da wasu abubuwa masu wuyar gaske don maye gurbin yatsunku yayin aiki. Kada a digo abubuwan kaushi na halitta akan allon taɓawa don gujewa rage rayuwar sabis.

C. Yi aiki mai kyau na maganin hana ƙura bayan kowane amfani da kayan aiki kuma tsaftace ƙurar a cikin lokaci.

D. Lokacin da kayan aikin ya yi kuskure, da fatan za a nemi ƙwararren don gyara ko gyara ƙarƙashin jagorancin ƙwararru.

lMatsalolin gama gari

7.1 Tambayar lokacin ganowa

Lokacin ganowa lamari ne mai matukar damuwa ga kowa, kuma koyaushe ina fatan in kasance cikin sauri da daidaito. Tun da ƙa'idar da ta gabata ta ƙayyade rabon zagayowar biyar na kunna wuta da lokacin kashewa ga kowane samfurin bayan mintuna 30 na preheating don ƙididdige sakamakon, yana da kusan ƙasa da sa'a guda don gwada bayanai ɗaya. Akwai irin wannan tunanin da aka riga aka yi wanda koyaushe ina jin cewa lokacin gwaji na yanzu Yayi tsayi. Lokacin preheating a cikin ƙayyadaddun hanyar yanzu yana jaddada buƙatar isa ga tsayayyen yanayi, maimakon ƙayyadaddun lokacin da ya gabata. Wannan saboda dalili ne. Saboda kewayon juriya na thermal na yadudduka yana da girma, yana buƙatar isa 35 ° C a gefe ɗaya da 20 ° C a wancan gefe. Lokacin da ake buƙata don tsayayyen yanayi ya bambanta. Misali, yana ɗaukar aƙalla sa'o'i 2 kafin riguna su isa daidai, yayin da jaket ɗin ƙasa suna ɗaukar tsayi. A daya bangaren kuma, yawancin masaku suna sha danshi. Kodayake samfurin an daidaita shi kuma an daidaita shi a gaba, yanayin gwajin ya canza. Zazzabi na tsohon shine 20 ℃ kuma zafi shine 65%, yayin da na ƙarshen shine 35 ℃ a gefe ɗaya kuma 20 ℃ a ɗayan. Danshin sake dawowa samfurin bayan ma'auni kuma ya canza. Mun yi gwajin kwatance. Nauyin tsohon samfurin guda ɗaya ya fi na baya girma. Kowa ya san cewa yana ɗaukar lokaci mai tsawo don sake daidaita danshin sake dawowa da yadudduka. Saboda haka, lokacin gano juriya na thermal ba zai iya zama gajere ba.

Har ila yau, yana ɗaukar lokaci mai tsawo don samfurin ya kai ga isothermal da rashin daidaituwa na ruwa yayin gwajin juriya na danshi.

Haka yake ga lokacin da ake buƙata don irin kayan aikin waje don gano "juriya na zafi da danshi", da fatan za a koma zuwa kari.

7.2 Tambayar girman samfurin

Girman samfurin yana da kyau koyaushe. Ba haka lamarin yake ba a gwajin juriya na thermal. Daidai ne kawai daga wakilin samfurin, amma ana iya zana kishiyar ƙarshe daga kayan aiki. Girman allon gwajin ya fi girma kuma dumama shine Uniformity matsala ce. Sabon ma'aunin yana buƙatar saurin iska na 1m/s. Girman girman, mafi girman bambancin gudun tsakanin mashigar iska da fitarwar iska, da kuma karuwa a yanayin zafin iskar da iska da zafin fitar da iska. Daga ci gaban ma'auni a gida da waje, zamu iya ganin cewa tsohuwar ma'auni shine mafi yawan 250mm2 kuma sabon ma'auni shine 200mm2. KES na Japan yana amfani da 100mm2. Sabili da haka, mun yi imanin cewa 200 mm2 ya fi dacewa da yanki mai tasiri a ƙarƙashin yanayin saduwa da ka'idojin hanya.

7.3 Ko saitin zafin jiki yana da alaƙa da ƙimar juriya na thermal

Gabaɗaya magana, yanayin saitin ba shi da alaƙa da ƙimar juriya ta thermal.

Ƙimar juriya na thermal yana da alaƙa da yanki na samfurin, bambancin zafin jiki tsakanin bangarorin biyu, da ikon da ake buƙata don kula da tsayayyen yanayin.

Rct

Da zarar an ƙayyade yanki na allon gwajin, kada girmansa ya canza. Muddin zafin jiki a ƙarshen duka biyu yana dawwama, ba shi da wahala a auna ƙarfin da ake buƙata don kula da kullun. Ana iya ganin zafin da ake amfani da shi ba shi da mahimmanci, idan dai zafin da ake amfani da shi bai canza kaddarorin abin da aka auna ba. iya. Tabbas muna mutunta ma'auni kuma muna ɗaukar 35 ℃.

7.4 An gano matsalar fihirisa

Me yasa sabon ma'auni ya soke ƙimar adana zafi kuma ya ɗauki fihirisar juriyar zafi? Za mu iya sani daga ainihin tsarin ƙimar adana zafi:

Q1-Babu samfurin zafi mai zafi (W / ℃)

Q2- tare da samfurin zafi mai zafi (W / ℃)

Tare da haɓaka aikin thermal, Q2 yana raguwa a layi, amma ƙimar insulation Q yana tashi a hankali. A zahirin amfani, ƙimar rufin zafi na mayafi mai Layer biyu da rigar mai Layer ɗaya yana ƙara ɗan ƙara kaɗan, ba ninki biyu ba. Wannan ƙirar ƙira ce Saboda haka, yana da kyau a soke wannan alamar a duniya. Abu na biyu, juriya na thermal yana da matukar dacewa don amfani, kuma ana ƙara ƙimar ta layi. Misali, gashin farko shine 0.085 m2 · K/W, kuma bene na biyu shine 0.170 m2 · K/W.

Dangantaka tsakanin juriya na thermal da ƙimar rufi:

Rct=A/Q2-Rct0 A: Wurin gwaji

Dangane da dabara, juriya na thermal yana canzawa bisa ga canjin Q2.

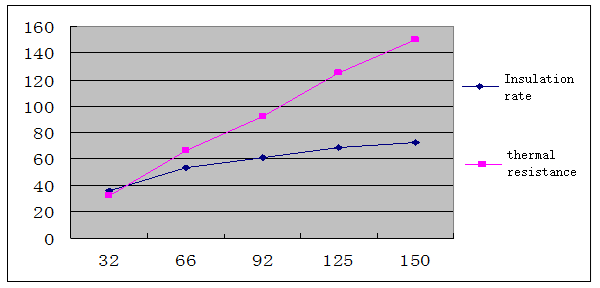

Misalai masu zuwa na bayanan gwajin juriya na thermal:

| Lokutan gwaji | 1 | 2 | 3 | 4 | 5 | Zafi mara kyau |

| Bayanan juriya na thermal (10-3m2K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

A 0.04m2kuma Q2 zai kasance:

| Lokutan gwaji | 1 | 2 | 3 | 4 | 5 | Bayanan juriya na thermal |

| Bayanin juriya na thermal 10-3m2K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

| Q2 (W/℃) | 0.4444 | 0.3226 | 0.2667 | 0.2186 | 0.1923 |

|

Q1 shi ne Babu samfurin zubar da zafi, Q1= A/Rct0=0.04/58*1000=0.6897

| Lokutan gwaji | 1 | 2 | 3 | 4 | 5 | Bayanan juriya na thermal |

| Juriya na thermal (10-3m2K/W) | 32 | 66 | 92 | 125 | 150 | 58 |

| Q2 (W/℃) | 0.4444 | 0.3226 | 0.2667 | 0.2186 | 0.1923 |

|

| Adadin insulation (%) | 35.57 | 53.22 | 61.33 | 68.31 | 72.12 |

|

Dangane da bayanan, zane mai lanƙwasa na juriya na thermal da ƙimar rufi:

t za a iya gani daga wannan cewa yayin da juriya na thermal ya zama ya fi girma, yawan ɗimbin ɗimbin ɗimbin ɗimbin yakan kasance mai faɗi, wato, lokacin da ƙarfin zafin jiki ya yi girma, yawan riƙewar zafi yana da wuya a nuna cewa yana da girma sosai.

7.5 Daidaita kayan aiki da matsalolin samfurin misali

Tabbatar da kayan aikin juriya na zafi da danshi ya zama babbar matsala. Idan za a auna zafin farantin ƙasa, ba za a iya gano shi ba saboda an kulle kayan aiki. Akwai abubuwa da yawa da suka shafi sakamakon gwajin. Hanyoyin tabbatarwa na baya suna da rikitarwa kuma basu warware matsalar ba. Sanannen abu ne cewa sauyin sakamakon gwajin na'urar da za a iya amfani da su ta thermal shine gaskiyar da ba za a iya jayayya ba. Bisa ga binciken mu na dogon lokaci, mun yi imani cewa ana amfani da "misali misali" don tabbatar da "mita juriya na thermal" "Ya dace da kimiyya.

Akwai nau'i biyu na daidaitattun samfurori. Ɗayan shine amfani da yadudduka (chemical fiber plain weave), ɗayan kuma soso ne.

Ko da yake ba a kayyade kayan masarufi a cikin ma'auni na cikin gida da na waje ba, ana amfani da hanyar superposition multilayer a fili don daidaita kayan aikin.

Bayan binciken mu, mun yi imanin cewa ba daidai ba ne a yi amfani da hanyar da aka fi dacewa, musamman ma kayan ado. Kowa ya san cewa bayan an sanya kayan yadi, akwai gibi a tsakiya, kuma har yanzu akwai iska a cikin rata. Juriya na thermal iska na tsaye ya fi sau biyu juriyar zafin kowane yadi. Girman rata ya fi girma fiye da kauri na yadi, wanda ke nufin cewa juriya na thermal da ke haifar da rata ba karami ba ne. Bayan haka, tazarar zoba ya bambanta ga kowane gwaji, wanda ke da wahala a gyara shi, yana haifar da tari na samfurori marasa daidaituwa.

Soso ba shi da matsalolin da ke sama. Samfurori na yau da kullun tare da tsayayyar thermal daban-daban suna da alaƙa, ba a cika su ba, kamar 5mm, 10mm, 20mm, da sauransu. Tabbas, an yanke kayan da aka yi amfani da su gaba ɗaya, wanda za'a iya la'akari da shi azaman kama (yanzu soso ne uniform Jima'i ne. mai kyau) Don bayyana cewa kumfa a cikin soso suna kama da juna, abin da ke sama yana nufin ƙarin rata tsakanin yadudduka.

Bayan da yawa gwaje-gwaje, soso abu ne mai matukar dacewa da aiki. Ana ba da shawarar cewa daidaitaccen sashin mai da hankali ya karbe shi.

Karin bayani

Gwajin tunani lokacin

| Samfurin iri-iri | Lokacin juriya na thermal (min) | Lokacin juriya da danshi (minti) |

| Yakin bakin ciki | Kusan 40-50 | Kusan 50-60 |

| Matsakaicin masana'anta | Kusan 50-60 | Kusan 60-80 |

| M masana'anta | Kusan 60-80 | Kusan 80-110 |

Lura: Lokacin gwajin da ke sama kusan yayi daidai da makamantan kayan aiki a duniya

Abubuwan da aka bayar na SHANDONG DRICK INSTRUMENTS CO., LTD

Bayanin Kamfanin

Shandong Drick Instruments Co., Ltd, ya fi tsunduma cikin bincike da haɓakawa, masana'antu da siyar da kayan gwaji.

Kamfanin da aka kafa a 2004.

Ana amfani da samfurori a sassan binciken kimiyya, cibiyoyin bincike masu inganci, jami'o'i, marufi, takarda, bugu, roba da robobi, sunadarai, abinci, magunguna, masaku, da sauran masana'antu.

Drick yana mai da hankali ga haɓaka gwaninta da ginin ƙungiya, yana bin ra'ayin haɓaka ƙwarewar ƙwarewa, sadaukarwa.pragmatism, da ƙima.

Yin riko da ka'idar abokin ciniki, warware mafi gaggawa da bukatun abokan ciniki, da samar da mafita na farko ga abokan ciniki tare da samfurori masu inganci da fasaha na ci gaba.