DRK503 Schildknecht Flexing Tester Operation Manual

Tlhaloso e Khutšoanyane:

Mehato ea tšireletseho 1. Matshwao a polokeho: Bukaneng ena, mehato ya polokeho le dintho tse latelang tsa bohlokwa di bontshwa ha o sebedisa seletsa. E le ho thibela likotsi le likotsi, ka kopo hlokomela lintlha tse latelang mabapi le kotsi, tlhokomeliso le tlhokomelo: Kotsi: Pontšo ena e bontša hore mokhanni a ka lemala haeba a sa lateloe. Tlhokomeliso: Lintho tse hlahisitsoeng li bonts'itsoe hore li ka ama sephetho le boleng ba liteko. Tlhokomeliso: The...

Mehato ea tšireletso

1. Matšoao a tšireletso:

Bukeng ena, mehato ea ts'ireletso le lintho tse latelang tsa bohlokoa tse bonts'itsoeng li bonts'oa ha u sebelisa sesebelisoa. E le ho thibela likotsi le likotsi, ka kopo ela hloko lintlha tse latelang mabapi le kotsi, tlhokomeliso le tlhokomelo:

| Kotsi: |

| Hlokomela: |

| Hlokomela: |

2. Sesebeling sena, matšoao a latelang a bontša tlhokomelo le temoso.

| Letshwao la tlhokomediso | Letšoao lena le bontša moo ho hlokahalang ho bua ka bukana ea ts'ebetso. | |

| Letšoao le kotsi la motlakase | Letšoao lena le bontša kotsi e phahameng ea motlakase. | |

| Letšoao la tšireletso la fatše | E bolela sebaka sa ho theola seletsa. |

Summary

1. Sepheo:

Mochine o loketse ho hanyetsa flexure khafetsa ea masela a koahetsoeng, ho fana ka boitsebiso bakeng sa ho ntlafatsa masela.

2. Molao-motheo:

Beha lesela le koahetsoeng ka mahlakoreng a mabeli ho pota-pota li-cylinders tse peli tse fapaneng e le hore mohlala o be cylindrical. E 'ngoe ea li-cylinders e khutlela morao ho axis ea eona, e bakang khatello e fapa-fapaneng le ho phomola ha moqomo oa lesela le koahetsoeng, e leng ho bakang ho phutha setšoantšong. Ho mena hona ha moqomo oa lesela le koahetsoeng ho tšoarella ho fihlela palo e reriloeng esale pele ea lipotoloho kapa mohlala o senyehile.

3. Maemo:

Mochine o entsoe ho latela BS 3424 P9, ISO 7854 le GB / T 12586 B mokhoa.

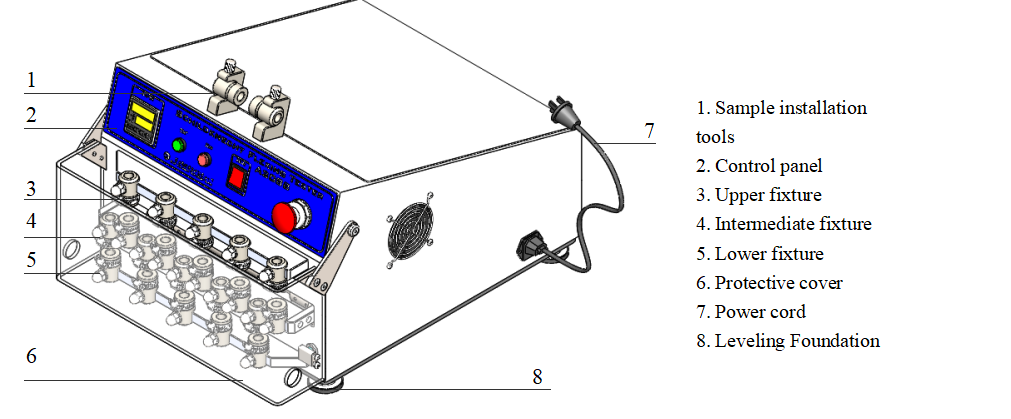

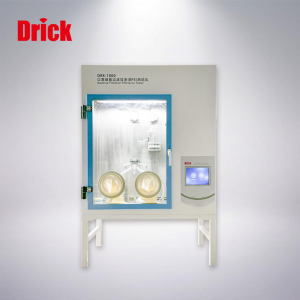

Tlhaloso ea seletsa

1. Sebopeho sa seletsa:

Sebopeho sa seletsa:

Tlhaloso ea Mosebetsi:

Fixture: kenya mohlala

Control panel: ho kenyelletsa sesebelisoa sa ho laola le konopo ea ho laola

Mohala oa motlakase: fana ka matla bakeng sa sesebelisoa

Leoto le lelefatsang: lokisa sesebelisoa sebakeng se rapameng

Lisebelisoa tsa ho kenya mehlala: ho bonolo ho kenya lisampole

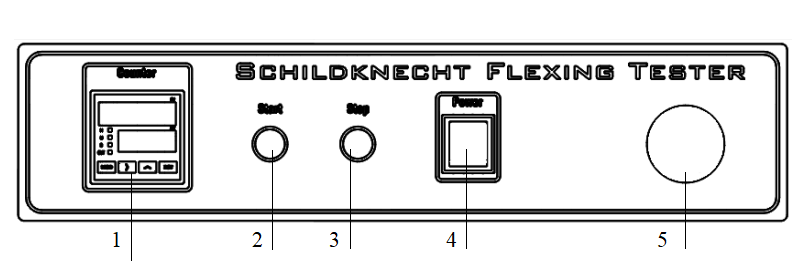

2.Tlhaloso ea phanele ea taolo:

Sebopeho sa "control panel":

1.Counter 2. Konopo ea ho qala 3. Konopo ea ho emisa

3.

| Morero | Litlhaloso |

| Tokiso | Lihlopha tse 10 |

| Lebelo | 8.3Hz±0.4Hz (498±24r/min) |

| Silinda | Bophara ba ka ntle ke 25.4mm ± 0.1mm |

| Teko ea teko | Arc r460mm |

| Leeto la teko | 11.7mm±0.35mm |

| Tlatsetsa | Bophara: 10 mm ± 1 mm |

| Sebaka se ka hare sa clamp | 36mm±1mm |

| Boholo ba mohlala | 50mmx105mm |

| Palo ea mehlala | 6, 3 ka bolelele le 3 ho latitude |

| Bolumo (WxDxH) | 43x55x37cm |

| Boima (hoo e ka bang) | ≈50Kg |

| Phepelo ea motlakase | 1∮ AC 220V 50Hz 3A |

4. Lisebelisoa tse thusang:

Clamp: likotoana tse 10

Wrench

Ho kenya lisebelisoa

1. Maemo a phepelo ea motlakase:

Ka kopo, lokisa motlakase o nepahetseng ho latela lengolo la mochini ona

| Kotsi

|

2. Litlhoko tsa tikoloho ea ts'ebetso: maemo a mocheso oa kamore.

3. Mochine o lokela ho behoa sethaleng se otlolohileng le se tsitsitseng ho boloka mochine o tsitsitse.

Tlhaloso ea ts'ebetso

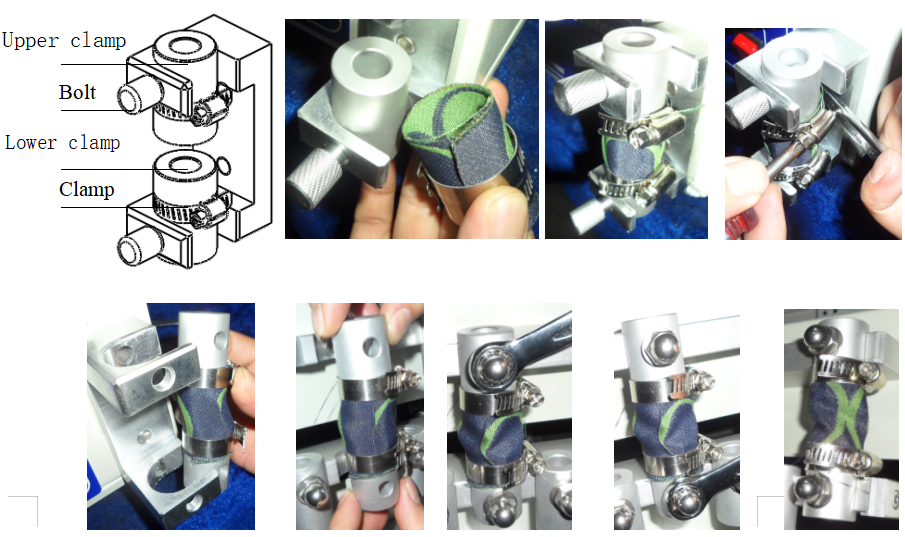

1. Tokiso ea likotoana tsa liteko:

1. Mohlala oa ho lokisetsa:

1.1 ho tloha moqolong o sebetsang oa lesela le koahetsoeng ka bophara, sehiloeng sampuli ea 60 mm x 105 mm, le mahlakore a 3 a malelele a bapileng ho thipa le weft ka ho latellana.

1.2 mohlala o tla khaoloa ho tloha ka nako e tšoanang ho pholletsa le bophara bo feletseng le bolelele ba mohlala

1.3 lokisa sampole: sampole e tlameha ho fetoloa ho leka-lekana ho 21 ± 1 ℃ le 65 ± 2% mongobo o amanang.

2. Mehato ea ts'ebetso:

2.1. Lintlha tse lokelang ho netefatsoa pele ho ts'ebetso:

Netefatsa hore na phepelo ea motlakase e fihlela litlhoko

Etsa bonnete ba hore sesebelisoa se sebetsa ka mokhoa o tloaelehileng

Hore na sets'oants'o sa sampole se suthang se maemong a mahareng

2.2. Mohlala oa ho kenya:

2.2.1 roala sekoaelo sa teko ea sampole ka har'a silindara ka hloko, 'me u behe li-clamp tse peli ka ntle ho silinda. Ebe u beha mohlala ka ntle ho li-cylinders. Ntlha ea pele, kenya li-cylinders tse peli ka har'a clamp ea setšoantšo se ntseng se hola, 'me u lokise lisilindara tse peli holim'a sethala ka bolt. Hlophisa lisampole ka tatellano, 'me u behe li-clamp tse peli lipheletsong tse peli tsa sampole haufi le mahlakore a ka hare a sehlomathiso.

2.2.2 notlela clamp ka screw driver, koala lipheletsong tse peli tsa sampole holim'a silinda, sebaka se pakeng tsa li-clamp tse ka holimo le tse tlase ke 36mm, 'me u notlele seqhomane ho tlamella karolo e ka holimo ea sampole.

2.3 ntša lithakhisa tse peli, ntša para ea li-cylinders tse kentsoeng le sampuli ho tloha setsing sa ho kenya (setšoan. 7), tsamaisa likoti tse pota-potileng tsa li-cylinders tse ka holimo le tse ka tlaase tse nang le li-screws holim'a setulo sa tlhahlobo ea teko (Setšoantšo sa 8). ), 'me u notle li-cylinders tse ka holimo le tse ka tlaase holim'a setulo sa ho lokisa ka wrench (Setšoantšo sa 9 ~ Setšoantšo sa 11)

2.4 kenya lisampole tse ling kaofela sethaleng sa tlhahlobo ea fixture ho latela mekhoa e hlalositsoeng mehatong ea 2.1 ~ 2.3

| Kotsi Ha u kenya le ho qhaqha cylinder le sampuli, etsa bonnete ba hore u tima motlakase oa mochine ho qoba kotsi ho opareitara. Ka mor'a hore cylinder e kenngoe setulong sa tlhahlobo ea teko, screw e tlameha ho notleloa ho qoba ho senya sesebelisoa. |

3. Qala tlhahlobo:

3.1 bulela phepelo ea motlakase, beha linako tsa liteko (palo ea linako ke ho hakanya palo ea linako tseo sampole e senyehileng mme e hloka ho emisoa hore e hlahlojoe) ebe o tobetsa konopo ea RST ho hlakola linako tsa hajoale tsa counter.

Tlhokomeliso: mokhoa oa ho beha nako: bulela sesebelisoa sa motlakase, tobetsa konopo ea kgutlotharo e ka ho le letona k'haontareng, nomoro e skrineng e thekesela ho ea ho boemo ba ho seta, tsoela pele ho tobetsa konopo ea kgutlotharo e nepahetseng ho fetola nomoro, tobetsa holimo. konopo ea kgutlotharo ho fetola boholo ba boleng (0 ~ 9 e bonts'oa ka ho latellana). Kamora hore tlhophiso e phetheloe, ema hoo e ka bang 8s hore skrine e khaotse ho benya, 'me tlhophiso e qala ho sebetsa

3.2 tobetsa konopo ea ho qala ho qala tlhahlobo, 'me mochini o tla emisa ka bohona ha palo e behiloeng e fihla

3.3 hlahloba boemo ba tlhahlobo ea sampole; haeba tlhahlobo e felletseng e hlokahala, tima switch ea motlakase ea mochini, tlosa sampole bakeng sa tlhahlobo, 'me u tlalehe linako tsa tlhahlobo.

3.4 haeba ho hlokahala ho tsoela pele ka tlhahlobo, tsosolosa linako tsa teko ho latela mokhoa o ka holimo

3.5 kamora tlhahlobo, tima motlakase 'me u theole lisampole tsohle bakeng sa tlhahlobo

| 【Hlokomela】 Ha e le hantle, sampole e tlositsoeng setulong e ke ke ea kenngoa sethaleng hape bakeng sa tlhahlobo; haeba ho hlokahala, sampole e ka kenngoa hape sethaleng bakeng sa tlhahlobo e eketsehileng kamora tumellano ea mekha eohle Haeba u batla ho emisa bohareng, tobetsa konopo ea ho emisa ho emisa ketso. |

3. Liphetho tsa tlhahlobo le tlaleho ea teko:

3.1. Tlhahlobo ea mohlala:

2.1.1

Ho senyeha ha ho roala sampuli;

Ho phatloha ho hoholo ha sampuli;

Mohlala o senyehile (o phatlohile)

3.1.2 tlhahlobo ea pele ha ho hlokahala, mohlala o ka ntšoa ka har'a silindara bakeng sa tlhahlobo e felletseng; ka mor'a hore liteko tsohle li phethoe, mohlala o tla tlosoa ho silinda bakeng sa tlhahlobo e qaqileng haholoanyane:

3.1.2.1 tlhahlobo ea ho kobeha le ho phunya ho hanyetsa:

Lintlha tsohle tse bonahalang, tse kang wrinkles, cracking, peeling le discoloration, li nkoa e le ho hlahloba ponahalo ea kakaretso. Mehlala e lekiloeng bakeng sa flexure le e se nang tlhahlobo ea flexure e bapisoa ntle le ho holisa. Limaraka tsa ho senyeha ha ponahalo li khethoa ho latela limaraka tse 'ne tse latelang,' me kereiti ea mahareng e ea amoheleha:

0 -- ha ho letho

1 - hanyane

2 - bohareng

3 - e tebileng

3.1.2.2 tlhaloso ea tšenyo: haeba e teng, mofuta oa tšenyo o tla boleloa.

3.1.3 ho petsoha: hlahloba mohlala ka hloko ka khalase e hōlisang makhetlo a 10 'me haholo-holo makhetlo a 10 ka microscope ea stereo. Haeba ho na le mapetsong, tlaleha botebo, bongata le bolelele ba mapetso ho latela lipehelo tse latelang.

3.1.3.1 botebo ba ho petsoha: mokhahlelo oa botebo ba crack o tjena:

Ni1 -- ha ho ho phatloha;

A - e petsoha ka holim'a bokaholimo kapa bokaholimo ba phetoho, 'me ha ho lesela la foam kapa lera le bohareng le ntseng le pepesitsoe.

B - ho phunyeha, empa eseng ka lera le bohareng, kapa tabeng ea ho roala ka lesela le le leng, lesela la substrate ha lea pepesoa;

C - ho phunyeletsa ho phunyeletsa lesela la motheo;

D-cracking e kenella ka botlalo linthong.

3.1.3.2 palo ea mapetsong: rekota boemo bo tlaase ka ho fetisisa ba mapetsong, bo emelang tekanyo e mpe ka ho fetisisa ea ho phunyeha. Haeba ho na le mapetsong a fetang 10, tlaleha feela "mapetso a fetang 10".

3.1.3.3 Crack length: rekota petso e telele ka ho fetisisa boemong bo tlase, e emelang tekanyo e mpe ka ho fetisisa ea ho phunyeha, e hlahisoang ka mm.

3.1.4 delamination: e le ho hlahloba hore na ho na le tekanyo e totobetseng ea delamination, teko ea phetoho e hlakileng ea matla a ho khomarela kapa ho apara, ho monya oli kapa ho hanyetsa khatello ea static e tla etsoa. Ho feta moo, botenya bohle ba mohlala bo ka khaoloa ho senola delamination sebakeng se belaelloang.

Tlhokomeliso ea 1: delamination e ka 'na ea se ke ea totobala, empa e ka etsa hore lesela le koahetsoeng le be bonolo ho apara, ho senya le ho monya oli, hape e ka fokotsa khatello ea eona e tsitsitseng.

Tlhokomeliso ea 2: Tsena ke liteko tse eketsehileng tsa boikhethelo, tse ikemetseng ka tlhahlobo ea flexure, 'me li ke ke tsa sebelisoa e le mokhoa oa ho hlahloba ho hanyetsa ha masela a koahetsoeng.

3.2. Tlaleho ea teko: tlaleho e tla kenyelletsa litaba tse latelang

Nomoro e tloaelehileng ea motheo oa tlhahlobo;

Lintlha tsohle tsa boitsebiso ba lesela le koahetsoeng;

Palo e boletsoeng ea flexure nakong ea tlhahlobo ea tlhahlobo le tlhahlobo le palo ea flexure tlhahlobo ea ho qetela;

Tekanyo ea ts'enyehelo ka tlhahlobo ka 'ngoe joalo ka ha e hlalositsoe Karolong ea 1;

Lintlha tsa ho kheloha hofe kapa hofe ho tloha mokhoeng o tloaelehileng oa tlhahlobo

| 【Hlokomela】 |

Mokhoa oa calibration

1. Ntho ea ho lokisa: lebelo

Sesebelisoa sa 2.Calibration: stopwatch ea elektroniki

3. Nako ea ho lekanya: selemo se le seng

4. Mehato ea ho lekanya:

4.1. Mokhoa oa ho lokisa lebelo:

4.2 bulela matla a mochini 'me u behe linako tsa liteko hore li fete 500

4.3 tobetsa konopo ea ho qala ho qala mochini le ho lumella nako ea stopwatch

4.4 ha stopwatch e fihla motsotso o le mong ho emisa nako, tobetsa emisa ho emisa mochini ka nako e le 'ngoe, 'me u hlahlobe hore na palo ea makhetlo a bontšitsoeng ke counter e lumellana le lebelo.

Mekhoa ea tlhokomelo

1. Sebaka sa mochine se lokela ho hloekisoa pele le ka mor'a tlhahlobo ka 'ngoe.

2. Oli e tlotsang e lokela ho ekeletsoa khafetsa karolong e potolohang ea mochini.

3. Ha mochine o sa sebetse nako e telele, polaka ea matla e lokela ho ntšoa.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Boemo ba Khoebo

Shandong Drick Instruments Co., Ltd, e sebetsa haholo ho etsa lipatlisiso le nts'etsopele, tlhahiso le thekiso ea lisebelisoa tsa tlhahlobo.

Khamphani e thehiloe ka 2004.

Lihlahisoa li sebelisoa likarolong tsa lipatlisiso tsa saense, litsi tsa tlhahlobo ea boleng, liunivesithi, liphutheloana, pampiri, khatiso, rabara le polasetiki, lik'hemik'hale, lijo, meriana, masela le liindasteri tse ling.

Drick o ela hloko temoho ea litalenta le kaho ea sehlopha, ho latela mohopolo oa nts'etsopele oa botsebi, boinehelo.pragmatism, le boqapi.

Ho latela molao-motheo o shebaneng le bareki, rarolla litlhoko tse potlakileng le tse sebetsang tsa bareki, 'me u fane ka litharollo tsa maemo a pele ho bareki ba nang le lihlahisoa tsa boleng bo holimo le theknoloji e tsoetseng pele.