Profiler precision measurement solutions SK4500

Short Description:

Profiler precision measurement solutions SK4500 Model:SK4500 Parameter features: 1.Three-axis Hall rocker control can be freely realized three-axis linkage to make the operation more convenient (left, right, up and down, the stylus up and down, the measurement of the start and stop a key to complete)2. Automatic detection Repeat measurement Single product batch detection3. The stylus is made of high hardness alloy imported materials, abrasion-resistant and durable.4. Software syste...

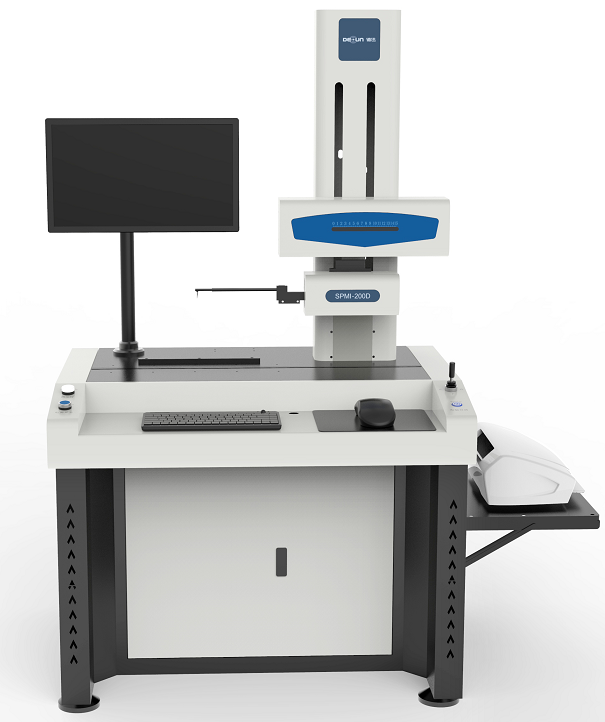

Profiler precision measurement solutions

SK4500

| Model:SK4500 Parameter features: |

| 1.Three-axis Hall rocker control can be freely realized three-axis linkage to make the operation more convenient (left, right, up and down, the stylus up and down, the measurement of the start and stop a key to complete)2. Automatic detection Repeat measurement Single product batch detection3. The stylus is made of high hardness alloy imported materials, abrasion-resistant and durable.4. Software system by the university professor tutor and senior professor of the shaft research institute with independent property rights and source code can be upgraded free of charge for life. |

Measuring principle:

The measuring principle of this instrument is right-angle coordinate measurement method, that is, through the X-axis, Z1-axis sensors, mapping out the surface contour of the measured parts of the coordinate points, through the electrical components, the sensor will be measured by the coordinates of the point data transmission to the upper PC, the software for the original coordinates of the collected data mathematical arithmetic processing, marking the required engineering measurement project.

This instrument can be compared with the performance of foreign imported instruments, the indicators have reached international standards, the instrument meets the national standards GB/T3505-2000, GB/T6062-2001, GB/T10610-1998, as well as international standards ISO5436, ISO11562, ISO4287 requirements.

The technical performance of the equipment:

1. Contour measurement function:

Dimension: including horizontal distance, vertical distance, linear distance, radius and diameter.

Angle: including horizontal angle, vertical angle, angle of pinch

Positional tolerance: including parallelism, perpendicularity

Shape tolerance: including straightness, convexity, arc contour degree

Auxiliary generation: including auxiliary points, auxiliary lines, auxiliary circles.

Parameter:

|

Test range |

X direction diver |

200mm |

|

|

Z1 |

Test range |

20mm |

|

|

Z1 |

Resolution:0.1 micron |

||

|

Z axis height(vertical column) |

550mm |

||

|

Mini diameter can be tested: |

10mm |

||

|

Profiler parameter |

Linear Accuracy |

±(0.7+|0.12H|)μm |

|

|

Circular Arc |

±(1.2+R/12)μm |

||

|

Angle |

±1′ |

||

|

Straightness |

0.5μm/100mm |

||

|

Evaluation length |

λc * 1、2、3、4、5 |

||

|

sensor |

type |

USA |

|

|

resolution |

0.1μm |

||

|

Country of origin |

USA |

||

|

Climbing angle |

77 degrees up 88 degrees down |

||

|

Measured speed |

0.05-20mm/s |

||

|

Z-axis speed |

0.05-20mm/s |

||

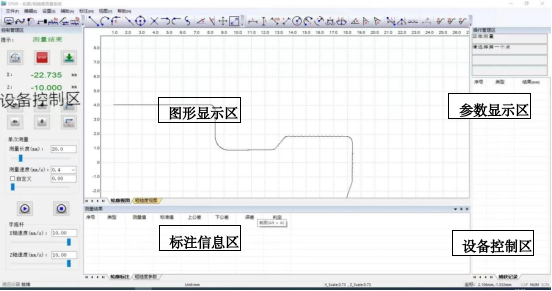

System screen:

The software system interface is shown in Fig. The system interface mainly includes: menu, toolbar, status bar, graphic display area labeling information area (contour labeling parameter list), system parameter display area, equipment control area.

Menu / toolbar: see the menu and toolbar part of the corresponding content.

Status bar: display the current operation tips, cursor coordinates in the graphic display area and other information.

System parameter display area: Used to display and set system parameters such as equipment parameters, measurement parameters and display parameters.

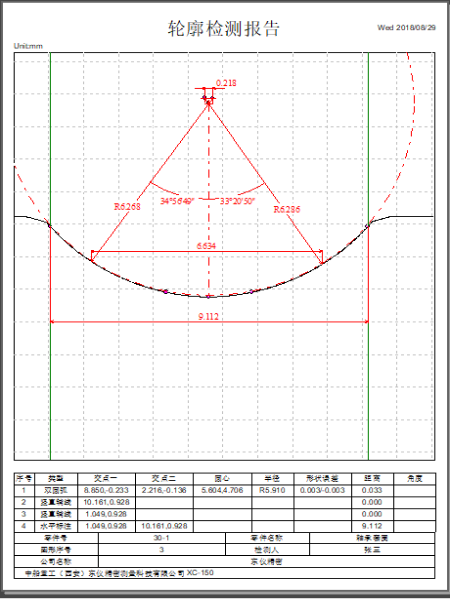

Print report

After the measurement, labeling and parameter evaluation of the parts are completed, the test results can be printed out. The user inputs the inspection report printing information (part name, part number, inspector, company name, etc.) and selects the format through the Print Information Setting dialog box.

Output options (contour / roughness graphics, contour labeling information list), view the print preview results that is the print results, as shown in the figure.

Selecting the print function at this point gives you the desired result – a nice test report!

Mainly configuration:

|

machine

Mechanical

Part

Parts

|

High quality Jinan green marble worktop |

The base and column are made of 00 grade marble. |

|

Marble Precision Upper and Lower Sliding Guides. |

Grinding grade high precision guide rail |

|

|

Motorized column system |

Taiwan Shangyin Linear Guideway |

|

|

Imported grating sensor |

Imported high-precision resolution digital grating |

|

|

Patented large angle adjustable table |

Positive tilt: ≥65° Negative tilt: ≥10 Horizontal adjustment system Y-direction adjustment: ±10mm |

|

|

Slewing and angle adjustment: ± 30° |

||

|

High Angle Adjustable Flat Nose Pliers Specification No.: DX2 Jaw width 50 Jaw depth 25 Opening degree 60 Adjustment angle 0-45° |

||

|

1 Set of calibration standards |

||

|

Styli and stems

|

Φ2*8*12°*0.025mm, carbide horseshoe stylus, 1pc |

|

|

Φ5*195mm, carbon fiber stylus, 1 pc. |

||

|

Electrical and additional parts |

Lenovo Computers |

I3-10 generation G6405 operating system 8G memory, 256G solid state to ensure high-speed operation, 21.5 LCD, wired keyboard and mouse kit |

|

Printers |

Japan HP color printer |

|

|

Factory certificates |

Qualified by the nationally recognized third-party calibration report. |

|

|

Software Diskette |

Software backup USB flash drive |

|

|

Warranty manuals |

/ |

|

|

Software manual |

/ |

|

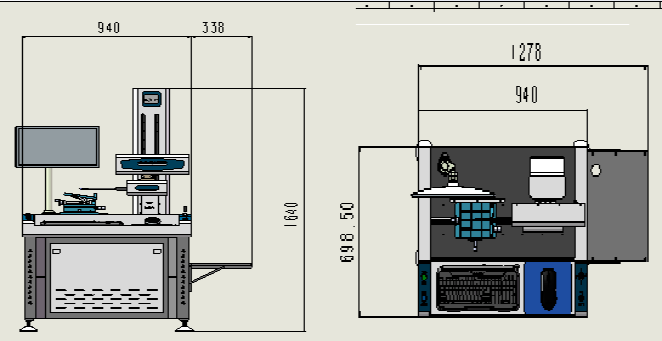

Size:

|

product |

Packaging size |

Total weight (Wt.kg) |

volume (CBM m³) |

||||||

|

Lx |

Ly |

Lz |

Wt(kg) |

Lx |

Ly |

Lz |

Wt(kg) |

||

|

1278 |

698 |

1640 |

180 |

1378 |

798 |

1700 |

50 |

400 |

1.39 |

Installation and commissioning training:

1, after the completion of equipment installation, the professional engineers (licensed) to carry out on-site training, and is responsible for teaching the demand-side operators the operation, use, repair and maintenance of equipment and software, as well as the actual sample testing and analysis work.

2, training content:

2.1 Equipment operation method.

2.2 Precautions for safe operation.

2.3 Introduction of equipment and function.

2.4 Daily maintenance and repair of the equipment.

Quality assurance and after-sales service:

Warranty period: 12 months from the date of installation and acceptance, but not more than 15 months from the date of shipment. Within this period, we are responsible for free maintenance of the machine failure caused by our reasons.

Outside the warranty period: I take regular visits and at any time the combination of telephone consulting after-sales service system, and strive to timely find and solve the user’s use of the difficulties and problems that exist for the user to provide technical advice.

The company is responsible for providing users with free technical consulting services for measurement and testing.

The company at cost price for life to provide users with equipment warranty services.

If the company receives the user’s equipment failure request service call, 24-hour response, if necessary, within 72 hours to send technicians to the scene to solve the problem.

The company has a spare parts library, life-long responsibility for the user at cost price to provide spare parts services.

The company is responsible for providing after-sales value-added services such as technical upgrading and remodeling at preferential prices for users for life.

If there is a regional office of our company in the user’s area, the regional office of our company will be fully responsible for its after-sales technical services.

Part of the customer site use pictures:

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.