OEM China Ross Folding Flexing Testing Machine - H0005 – Hot Tack Tester – Drick

Short Description:

The Hot Tack Tester is an advanced system for monitoring the seal performance of flexible and semi rigid plastic bags or tubes. The design and development of the packaging system has come under close scrutiny with a great deal of emphasis placed on the integrity of the final product. Although factors such as type of package, materials of construction, size and desired outcome all add to the equation of flexible package integrity, the seal strength is an important element. The Hot Tack ...

OEM China Ross Folding Flexing Testing Machine - H0005 – Hot Tack Tester – Drick Detail:

The Hot Tack Tester is an advanced system for monitoring the seal performance of flexible

and semi rigid plastic bags or tubes.

The design and development of the packaging system has come under close scrutiny with

a great deal of emphasis placed on the integrity of the final product. Although factors such

as type of package, materials of construction, size and desired outcome all add to the equation

of flexible package integrity, the seal strength is an important element.

The Hot Tack Tester has been developed to determine the capability of a heat-seal join to

hang together when it is stressed, at a specified time interval, while still hot from the

sealing operation, but before it reaches ambient temperature. The overall design of a package

can contribute or detract from the materials ability to provide hot tack during the sealing

process.

Hot tack knowledge is a considerable concern as package seals must be able to withstand

forces and stresses applied during the form filling process. By assessing the quality of seals

key parameters, (sealing pressure, dwell time and temperature) optimum sealing conditions

can be determined and therefore reflected on the production line. This new Hot Tack

technology will aid in the research and development of flexible films used in the packaging

industry.A must have in any modern day quality laboratory.

Benefits:

Provides the user a means of determining key sealing parameters.

The simple process is quick and easy.

Useful for quality control.

Precise, repeatable test circuits.

Able to test and inspect incoming material.

Data can be viewed in a graph or numerically.

Related to product development and quality control through the

whole manufacturing chain of flexible packages.

Optimisation of the packaging process.

Optional ability to record data for future comparisons via RS232.

Optional ability to print results for hard copy storage.

Complies to ASTM F1921

Touch Screen Operation

Operation:

The Hot Tack test Setup page is used to allow the Operator to enter the required

parameters of a test. These include:

Test Nr Thickness Operator Temperature Lab Temp Dwell time Humidity

Seal pressure Sample Width Cooling time Separation rate

Once the test parameters have been selected by the operator, the sample strip can be

loaded into the sample clamps before pressing Start at which stage the Hot Tack Tester

automatically places the sample between the heated sealing jaws, closing the jaws for the

preselected time in milliseconds, removing the sealed sample strip and, with no delay, begins

the peeling process.

Set Up Screen

The Hot Tack Test prompt page will appear after a Sample test has been completed.

The Operator must then enter the Failure Mode. The standard points out that a number

of different failure modes could occur in the course of the failure of the strip, the Hot Tack

Tester allows an operator to enter one of seven Failure modes. If the operator is not satisfied,

then the Repeat Cycle button can be touched, the test will not record any results and the

Cycle and Sample number will remain the same.

Specification:

Sealing Temperature: Ambient

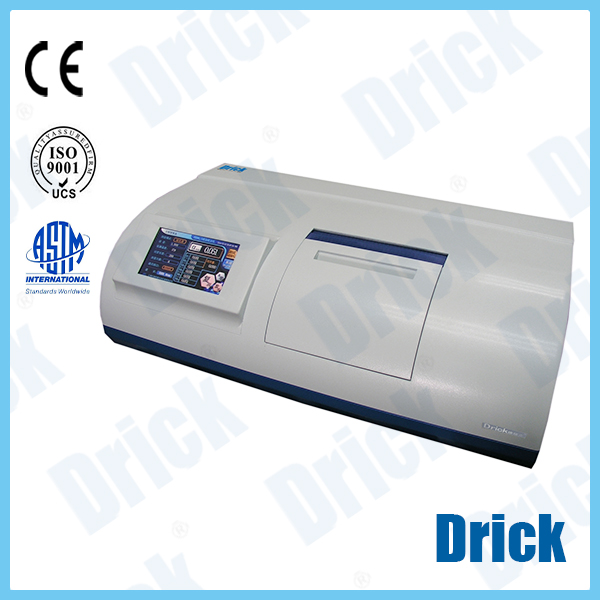

Product detail pictures:

Related Product Guide:

Discount EKG Machines Make Home Testing Easier

Points To Consider While Choosing Lab Testing Machines for Your Industrial Laboratory

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for OEM China Ross Folding Flexing Testing Machine - H0005 – Hot Tack Tester – Drick, The product will supply to all over the world, such as: Colombia, Pretoria, Leicester, We have more than 8 years of experience in this industry and have a good reputation in this field. Our products have won praise from customers worldwide. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.