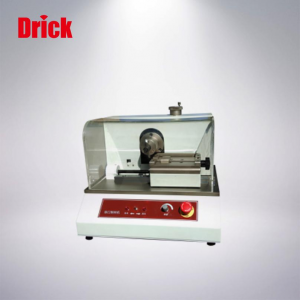

Notch Sample Making Machine DRKANM-II

Short Description:

DRKANM-II Notch Sample Making Machine Introduction DRKANM-II Notch Sample Making Machine is used to make the notch sample for cantilever beam, simply supported beam impact test, which can be used by scientific research institutions, colleges and universities, non-metallic material manufacturers and related quality inspection institutions and other units to make notch samples. It is a simple structure, convenient operation, and can mill one sample at a time with multiple samples and high acc...

DRKANM-II Notch Sample Making Machine

Introduction

DRKANM-II Notch Sample Making Machine is used to make the notch sample for cantilever beam, simply supported beam impact test, which can be used by scientific research institutions, colleges and universities, non-metallic material manufacturers and related quality inspection institutions and other units to make notch samples. It is a simple structure, convenient operation, and can mill one sample at a time with multiple samples and high accuracy.

Principle

Using mechanical cold machining rotary cutting mode, you can manually feed the cutting depth, after completing the notch production of the sample, you can drive back to the cutting origin, the operation is extremely convenient.

Features

l Triple safety protection device

There are left and right limit protection, there are anti-collision limit switches to ensure that the feed device moves within a limited range, the cutting power supply is left alone to prevent the possibility of people inadvertently starting the cutting motor, and the protective cover can fall to touch the cutting motor rotation power supply closure is to protect the 100% safety of the test personnel.

l This product adopts automobile painting process, beautiful appearance

Use a 9-layer car painting process to keep the color bright forever and beautify your office environment.²

l High reliability and stability

The feed motor and rotary cutting motor provided by the well-known supplier (Zhejiang Jiaxue) and the button provided by Hongbo Group ensure that all the devices are stable and reliable.

Technical parameters:

Ø Rotating motor speed: 240r/min;

Ø Tool stroke: 20mm;

Ø Machining notch depth: 0 ~ 2.5mm adjustable;

Ø table stroke: > 90mm;

Ø Number of specimens each time: 20;

Ø Tool type parameters: Type A tool 45°±1° r=0.25±0.05(mm);

Type B tool 45°±1° r=1.0±0.05(mm);

Type C tool 45°±1° r=0.1±0.02(mm);

Note: The above tool type, the user can choose one according to the actual demand.

Ø Power supply: AC220V±15% single-phase three-wire system.

Compliant standard

| Standard | Standard name |

| ISO179-2000 | Measurement of impact strength of plastic simple supported beams |

| ISO180-2000 | Plastic Izod impact strength determination |

| GB/T1043-2008 | Measurement of impact properties of plastic simple supported beams |

| GB/T1843-2008 | Measurement of impact strength of plastic cantilever beams |

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.