Uv aging test is mainly applicable to the aging test of non-metallic materials and artificial light sources. uv aging test uses fluorescent ultraviolet lamp as the light source, through the simulation of natural sunlight in the ultraviolet radiation and condensation, to accelerate the weathering test of the material, in order to obtain the results of the weathering resistance of the material.

It can simulate environmental conditions such as ultraviolet, rain, high temperature, high humidity, condensation, and darkness in the natural climate, and combine them into a cycle by reproducing these conditions, and let it automatically perform the number of completed cycles.

Test purpose

UV aging test provides reliable data to make accurate correlation prediction of product weather resistance (anti-aging), and helps in the screening and optimization of materials and formulations.

Scope of application

It is mainly suitable for automobile motorcycle, building materials, textiles, furniture leather and other industries.

Test standards for UV aging test:

ASTM G154 Fluorescent UV Lamp Exposure test Procedure for non-metallic materials

ASTM D4329 Fluorescent UV exposure test for plastics

ASTM D4587 Coating Aging Test (UV Aging)

ISO 4892-3:2006 Exposure to laboratory light sources – fluorescent ultraviolet lamps

ISO 11507 coating exposed to fluorescent UV lamps and water;

SAE J2020 UV rapid aging test for automotive exterior materials;

ASTM D4799, D5208, G154, G151;

ISO 4892-3, 11507, 11895, 11997-2;

EN 927-6, 1297, 12224, 13523-10, 1898, pr 1062-4;

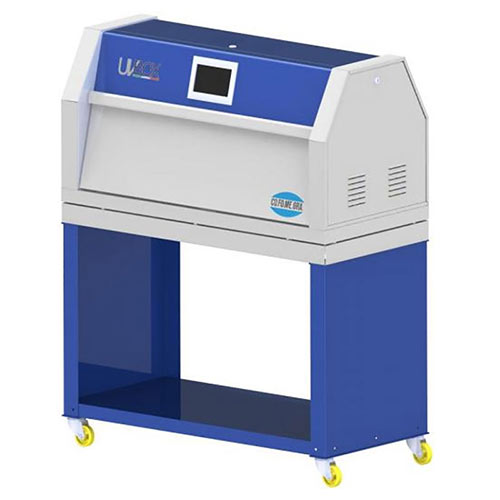

The CO.FO.ME.GRA UV aging chamber simulates the effects of ultraviolet light with UV lamps and reproduces dew and rain through condensation and water spray. Accelerated UV aging tests reproduce the damage caused by sun, rain and dew. After exposure of samples in the CO.FO.ME.GRA UV aging chamber for a few days or weeks, damage that occurs during months or years of outdoor exposure can be reproduced. In order to simulate aging caused by external atmospheric factors, the CO.FO.ME.GRA UV aging chamber subjected the material to alternating cycles of ultraviolet radiation and humidity at controlled high temperatures. The instrument simulates the effects of daylight by using a special UV fluorescent lamp, and the effects of dew and rain by condensing or spraying water (spray option).

Almost all photodegradation processes of durable materials exposed to the external environment are caused by ultraviolet radiation. The fluorescent lamps used in the CO.FO.ME.GRA UV aging chamber simulate the critical UV shortwave wave and realistically reproduce the damage caused by sunlight. The types of damage that can be simulated in the CO.FO.ME.GRA UV aging test chamber are: discoloration, loss of light, powder, cracking, cracking, foaming, veiling, brittleness, strength loss and oxidation.

Dew is primarily responsible for most of the moisture produced during outdoor exposure, not rain. The condensation system in the CO.FO.ME.GRA UV aging chamber can realistically simulate dew and amplify its effect through high temperatures. The condensation process automatically purifies the network water used in the system. This is because the evaporation and condensation process of water on the sample is actually a distillation process that removes all impurities. The CO.FO.ME.GRA UV aging chamber can hold up to 48 standard samples (75 mm x 150 mm), and special sample racks can be created according to customer specifications.

Scope of application:

The innovative design of the CO.FO.ME.GRA UV aging test chamber achieves higher standards in terms of performance characteristics, ease of use, accuracy and safety compared to other UV fluorescent aging test chambers, and its verification performance meets or even exceeds that of other brands. Multilingual touch screen interface, data acquisition via Ethernet connection, high security, optional recirculation spray. More unique features for easy user operation and use.

Send your message to us:

Post time: Sep-25-2024