Laser Particle Size Analyzer DRK-G200

Short Description:

DRK-G200 Laser Particle Size Analyzer DRK-G200 laser particle size analyzer features a split design, separating the sampler from the main unit. It supports both wet and dry detection dispersion methods, enabling more convenient mode expansion and conversion. With its plug-in pipeline design, switching the detection method can be accomplished by simply pairing the appropriate sampler and detection window. Additionally, users can choose to configure micro-volume, large-capacity, or corrosion-...

DRK-G200 Laser Particle Size Analyzer

DRK-G200 laser particle size analyzer features a split design, separating the sampler from the main unit. It supports both wet and dry detection dispersion methods, enabling more convenient mode expansion and conversion. With its plug-in pipeline design, switching the detection method can be accomplished by simply pairing the appropriate sampler and detection window. Additionally, users can choose to configure micro-volume, large-capacity, or corrosion-resistant sampling systems.

DRK-G200 laser particle size analyzer is based on the full-range Mie scattering theory. Its design fully complies with ISO international technical standards. Structurally, it uses a pure helium-neon gas light source and a large-angle, non-uniform, crossed, three-dimensional, double-row, fan-shaped, super-large detector array. This design takes full account of the detection angle and sensitivity, ensuring a wide testing range as well as the accuracy and repeatability of the test results.

Wet Dispersion

The ultrasonic dispersion system of the DRK-G200 laser particle size analyzer can fully disperse the sample to be tested. The high-power ultrasonic generator (100W) is equipped with a dry-running protection design. The ultrasonic time can be adjusted automatically and continuously, allowing users to set it according to the difficulty of sample dispersion. With excellent shielding, ultrasonic dispersion and sample testing can be carried out simultaneously. Even particles with strong agglomeration can be fully dispersed, ensuring the acquisition of accurate particle size distribution data.

The sample dispersion cell is made of stainless steel and has a unique circular design, facilitating liquid circulation and drainage. The Teflon coating provides strong corrosion resistance, and the micro-arc design prevents dirt accumulation, making cleaning easy. It also comes with a liquid level protection and anti-overflow device.

The wet dispersion method offers automated functions such as automatic water inlet, automatic testing, automatic optical path status determination, automatic bubble elimination, and automatic cleaning. Liquids like distilled water, pure water, and alcohol can be used as the dispersion medium.

Circulation Stirring System

Select an appropriate circulation stirring speed based on the characteristics of the sample to be tested to prevent particle sedimentation in the circulation pipeline. The circulation pump speed can be adjusted automatically and continuously, with a digital display for settings. When the ultrasonic function is turned on during the testing process, it can avoid testing errors caused by bubbles generated due to excessive circulation speed and prevent particle agglomeration during the circulation process.

Dry Dispersion

The sample is evenly conveyed into the high-pressure airflow through the automatic dry powder sampler. Driven by the high-pressure airflow, it is continuously and rapidly sprayed into the disperser. By the time it reaches the outlet of the disperser, the sample is fully dispersed. After passing through the laser beam, the sample enters the collector or vacuum cleaner, and the particle size distribution information is immediately displayed on the computer.

- For dry dispersion, no dispersant or solvent is required. The dispersion principle is shown in the following figure.

- It uses a silent, oil-free air compressor, paired with an efficient condenser to ensure the production of pure compressed air.

- It enables instantaneous dispersion and measurement, with high testing accuracy and fast analysis efficiency. The process from sample injection to result output is completed instantaneously.

- It has automatic sample injection and supports fully automatic one-key operation.

- The unique duck-bill-shaped nozzle significantly improves the detection stability and accuracy.

| Specification Model | DRK-G200W (Wet), DRK-G200D (Dry), DRK-G200 (Wet and Dry Dual-Use) |

| Testing Range | Wet: 0.02 – 2000μm Dry: 0.1 – 2000μm |

| Repeatability Error | < 1% (National Standard Reference Material D50) |

| Measurement Principle | Mie Scattering Principle |

| Accuracy Error | < 1% (National Standard Reference Material D50) |

| Measurement Method | Wet: Stirring and Ultrasonic Dual-Stage Dispersion Dry: Duck-Bill-Shaped Nozzle, Oscillation and Venturi Dual-Stage Dispersion |

| Optical Path System | High-Transmittance Coated Single Lens, High-Precision Three-Dimensional Automatic Centering, Optical Path Automatic Determination and Warning Function |

| Laser Light Source | Pure Helium-Neon Gas Laser |

| Sample Cell | 400ml Micro-Arc Bottom, with Physical Liquid-Level Meter, Designed to Prevent Particle Aggregation and Deposition |

| Detector | Sensitive Large-Area Detection Units, Distributed in Front, Rear, and Side Double-Row Three-Dimensions |

| Operation Method | Both wet and dry methods support one-key full-automatic and manual operation |

| Circulation Rotation Speed | Up to 5000 revolutions, continuously adjustable |

| Ultrasonic Generator | 100W, adjustable from 0 – 9 minutes and 50 seconds, with dry-running protection design |

| Interface Method | Dual Communication of Network Port and USB |

| Instrument Structure | Split-Type, Metal Body, Quick-Insert Pipelines |

Application Scope

It is suitable for particle size analysis and testing in various fields, including powder coatings, building materials (cement), metallurgy and chemical engineering, coal and minerals, pharmaceuticals and pesticides, health products, ceramic abrasives, catalysts, precious metals, etc. Examples include heavy calcium carbonate, light calcium carbonate, talcum powder, kaolin, graphite, wollastonite, brucite, barite, mica powder, bentonite, diatomite, clay, silica, garnet, zirconium silicate, zirconia, magnesium oxide, zinc oxide, river sediment, lithium-battery materials, catalysts, phosphor powders, cement, abrasives, pharmaceuticals, pesticides, food, coatings, dyes, ceramic raw materials, chemical materials, nanomaterials, paper-making fillers and coatings, and various emulsions. Based on the design principle of the all-round laser particle size analyzer, it can be used to detect not only solid powder particles but also mixed solutions such as suspensions and emulsions.

Analysis Software

- The PADMAS (Particle Diameter Measure & Analysis System) is a powerful and feature-rich software. It can process test data through functions such as averaging, statistics, comparison, and trend analysis. It offers multiple formats, including differential distribution, cumulative distribution, standard classification, volume distribution, area distribution, number distribution, R-R distribution, custom classification, and classification by mesh size.

- High Visibility: The testing software has a user-friendly interface. The testing process is clearly visible, with instant refresh, allowing users to observe the operating status of the instrument and the fluctuation of test data at any time, and analyze the authenticity and reliability of the measured data.

- Objective and Real: The analysis software performs automatic calculations.

- Easy to Operate: Standardized, quantitative, and simple operations can be mastered in a short time.

For customers in the pharmaceutical industry, the software complies with the GMP regulations of the Pharmacopoeia. It has functions such as audit trail, electronic signature, permission setting, data immutability, and can provide 3Q templates to assist in 3Q certification.

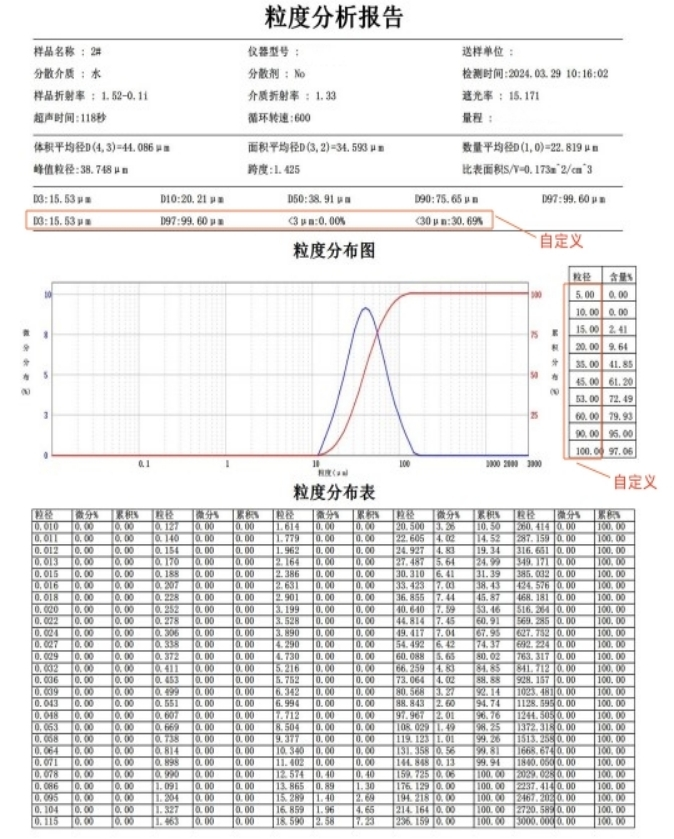

Test Report

The test report includes a particle size distribution curve, a detailed particle size data table, and a custom simple table. It contains characteristic parameters such as D3, D10, D50, D90, D97, D(1,0), D(3,2), D(4,3), span, peak particle size, and specific surface area. There are also multiple custom parameters that can be input as needed. The weight-based specific surface area and volume-based specific surface area can be interchanged. The particle size distribution graph and particle size data chart can be saved as pictures. It also supports PDF, WORD, and EXCEL report templates. It supports printing test reports in Chinese and English. The header and footer can be modified as required, and there is a print preview function.

Note: Due to technological advancements, the information may be updated without prior notice. The product shall be subject to the actual product delivered later.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.