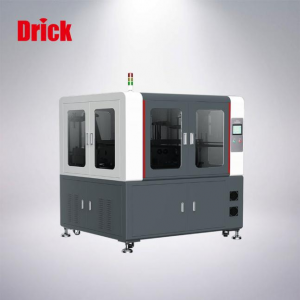

DRK9007AG Air Filter Element Filtration Performance Tester

Short Description:

Instrument use: It is used to test the dynamic adsorption performance of automobile air-conditioning filters that can reduce the concentration of harmful gases and odors from the external environment or internal circulation. Standards compliant: GB/T32085.2-2015、ISO11155-2:2009、QC/T795.2-2007 Instrument characteristics: 1. The resistance pressure difference of the filter material will be obtained through the static pressure ring of the upstream and downstream test chambers, and the high-p...

Instrument use:

It is used to test the dynamic adsorption performance of automobile air-conditioning filters that can reduce the concentration of harmful gases and odors from the external environment or internal circulation.

Standards compliant:

GB/T32085.2-2015、ISO11155-2:2009、QC/T795.2-2007

Instrument characteristics:

1. The resistance pressure difference of the filter material will be obtained through the static pressure ring of the upstream and downstream test chambers, and the high-precision imported brand pressure difference transmitter will be used to ensure the accuracy and stability of the pressure difference.

2. Double sensors are used to collect upper and lower concentrations at the same time to ensure accurate, stable, fast and effective sampling.

3. The system tests the air intake and passes through a high efficiency filter (HEPA) to remove suspended particles introduced into the air. There is a voltage stabilization and flow stabilization device installed inside to ensure the stability of the detection flow, and the automatic control system is simple, fast and stable.

4. Pollutants enter the air after being effectively filtered and absorbed.

5. Equipped with a 10-inch touch screen, the test results are directly displayed on the interface, the user can choose to directly or save the data, and is equipped with a remote network module, which can directly upgrade the equipment remotely.

6. The user only needs to place the sample in the fixture, press the button, and after adjusting the test flow, the system will automatically test the resistance and efficiency through the controller (PLC). The whole process is simple, fast and efficient.

7. Standard n-butane test sensor, optional toluene, sulfur dioxide or other gas sensors.

8. Integrated airflow resistance test function, which can detect airflow resistance according to different settings.

9. Negative pressure test mode, to prevent the test gas from entering the surroundings and affecting the health of testers.

10. The instrument is equipped with an environmental control room, and the user does not need to prepare an environmental room separately.

Technical parameter:

1. n-butane sensor

(1) Measuring range: 0ppm~100ppm;

(2) Resolution: 0.01ppm;

(3) Accuracy: ≤±3%;

(4) Corresponding time: ≤30s;

(5) Explosion-proof grade: intrinsically safe type;

2. Test range of adsorption efficiency: 0~100%, resolution: 0.01%;

3. Penetration efficiency = 100%-adsorption efficiency, resolution: 0.01%;

4. Air flow: (100~600) m3/h, accuracy: ≤±2%

5. Inlet pressure of contaminants: 0~1000kPa, resolution: 0.1kPa, accuracy: ≤±0.5%;

6. Inlet flow rate range of contaminants: 0~30SLM, accuracy: ≤±1%;

7. Temperature measurement range: 0℃~50℃, accuracy: ≤±0.5℃;

8. Humidity measurement range: 20%RH~98%RH, accuracy: ≤±2%;

9. Resistance test range: 0~10kPa, resolution can reach 1Pa, accuracy: ≤±0.5%;

10. Test environment: (23±3)℃, (50±2)RH%;

11. Power requirements: AC220V, 50Hz, 1.5kW;

12. Overall dimensions (L×W×H): 1200mm×800mm×1650mm;

13. Weight: about 220Kg.

Technical parameters of constant temperature and humidity chamber:

1. Temperature control range: 20℃~30℃;

2. Temperature control accuracy: ≤±2℃;

3. Humidity control range: 40%RH~70%RH;

4. Humidity control accuracy: ≤2%RH;

5. Overall dimensions (L×W×H): 1800mm×1500mm×2000mm;

6. Internal dimensions (L×W×H): 1500mm×1200mm×1800mm;

7. Voltage requirements: AC380V, 8kW.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.