DRK313 Mask Tightness Tester Operation Manual

Short Description:

■ Standard ITEM MODEL QTY Main Unit 1 AC Adapter(100-240V、12V 2A) AF90-ADP 1 Power Cord 1 Zero Filter 1 Alcohol Storage Container AF90-AFC 1 Storage Cap AF90-CAP 1 Alcohol Cartridge AF90-ACR 1 Spare Felt/Wire Mesh AF90-AWK 2 Software CD 1 Tygon Tube (1m) 1 Carrying Case 1 ■ Consumables ITEM MODEL QTY Zero Filter 1 Alcohol Cartridge 1 Spare Felt / Wire Mesh 2 For more details about the consumable...

■ Standard

|

ITEM |

MODEL |

QTY |

| Main Unit |

1 |

|

| AC Adapter(100-240V、12V 2A) | AF90-ADP |

1 |

| Power Cord |

1 |

|

| Zero Filter |

1 |

|

| Alcohol Storage Container |

AF90-AFC |

1 |

| Storage Cap |

AF90-CAP |

1 |

| Alcohol Cartridge |

AF90-ACR |

1 |

| Spare Felt/Wire Mesh |

AF90-AWK |

2 |

| Software CD |

1 |

|

| Tygon Tube (1m) |

1 |

|

| Carrying Case |

1 |

■ Consumables

|

ITEM |

MODEL |

QTY |

| Zero Filter |

1 |

|

| Alcohol Cartridge |

1 |

|

| Spare Felt / Wire Mesh |

2 |

For more details about the consumables, please contact your distributor.

Laser Classification

This device is classified as a Class 1 Laser Product in accordance with the following standards:

EN60825-1: 2007

I EC60825-1: 2007

CLASS 1 LASER PRODUCT

I EC60825-1: 2007

*Class 1 Laser:

Lasers that are considered to be safe under reasonably foreseeable conditions of

operation, including the use of optical device for intrabeam viewing.

Laser Safety Information

Warning - This device employs a laser inside the unit as the light source of the sensor. Do not open/close the case of unit or disassemble the optical sensor inside the unit.

| Wave length |

650nm |

| Maximum output |

20mW |

Caution - Any attempt by user to control, adjust, or perform maintenance procedures other than those specified in this manual may result in hazardous exposure to laser radiation.

Important Safety Information

The symbols for the warnings used in this manual are defined below:

Classifications

Warning:

Warnings in this classification indicate risks that may result in serious injury or death if

not observed.

Caution:

Warnings in this classification indicate risks that may result in damage to the product and

which may void the product warranty if not observed.

Description of Symbols

symbol indicates a condition that requires caution (including warning). The subject of each caution is illustrated inside the triangle. (e.g. the high temperature caution symbol

is shown on the left.)

symbol indicates a prohibition. Do not take the prohibited action shown inside or near this symbol. (e.g. the disassembly prohibition symbol is shown on the left.)

symbol indicates a mandatory action. A specific action is given near the symbol.

|

Warning |

|

○ Do not disassemble, modify, or attempt to repair the device. …… A 3B laser diode is used as the optical source inside the device. Never attempt to disassemble the device as it is potentially extremely Do not modifydangerous.Also, disassembling the unit may result in a or disassemblemalfunction. |

|

○ Use the device properly by carefully following this operation manual. …… As with any electric device misuse may result in electric shock, fire, Handle properlydamage to the instrument, etc. |

|

Do not use this instrument in ambient temperature of 35℃ (95℉) or greater. Prohibited…… The performance may deteriorate significantly and component damage installationmay result. |

|

○ When the instrument is not in use, unplug the power cord. …… Failure to observe the above may result in electric shock, fire or damage to the internal circuit.

○ Install the instrument in a location where the power cord is accessible such that you can disconnect the power cord easily. ○ When using the power cord, make sure that the plug is clean and dry. ○ The AC outlet must be within the specified power requirement. …… Failure to observe the above may result in fire.

○ Use only the power cord and/or the AC adapter provided with this instrument. …… Other commercially available cords may have different voltage specifications and polarity, which may result in short circuit, fire or damage to the instrument.

○ While charging the battery with the instrument, do not remove the battery from the instrument. …… Failure to observe the above may result in battery leakage and damage to the circuitry. |

|

Caution |

|

○ Do not use or leave this instrument in an environment exceeding or falling below the specified temperature/RH levels for the instrument. The instrument should not be exposed to direct sunlight for a prolonged period of time. Prohibition…… This instrument may not function properly beyond the specified operable environment. (10 to 35℃, 20 to 85%RH, with no condensation) |

|

○ Do not use volatile solvents to clean the instrument. …… The case of the main unit may be damaged by organic solvents. Use a soft dry cloth to remove any dirt.If this is not effective, the user may soak the cloth in neutral detergent or water and wipe the Prohibitioninstrument with the cloth. Never use volatile solvents such as thinner or benzene. |

|

|

○ Do not subject the instrument to strong shocks.Do not place heavy objects on the instrument. …… Failure to observe the above may cause malfunction or damage to the Prohibitioninstrument. |

|

○ If the instrument has been stored in a cold environment, allow the instrument to come to temperature equilibrium with the environment in which it will be operated before turning it on.

Prohibition……Even when the instrument is used in the specified operating temperature and humidity, a sudden temperature change may cause condensation. Condensation on the sensor may cause inaccurate measurements or in extreme situations, could damage the internal components. |

|

○ Do not allow static electrical discharge to the instrument. …… Failure to observe the above may affect the measurement value and cause damage to the instrument circuitry. |

|

○ Do not let the instrument draw in highly concentrated particles that exceed the specification level. (i.e., >100,000 particles/cc) Handle properly |

|

○ Do not dispose of the instrument as Non-electronic waste. …… Please note that any disposal of the instrument should be in line with your local or national regulation. ProhibitionFor details, please contact your local distributor. |

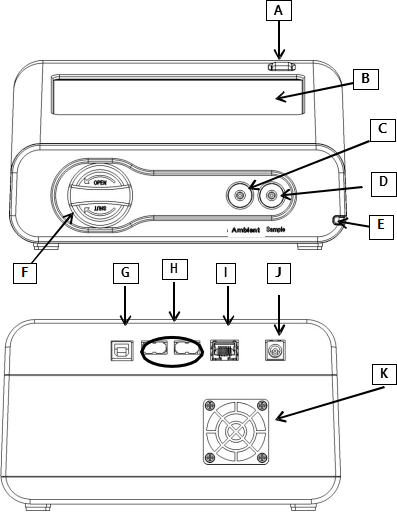

1. Part Names and Functions

1.1Main Unit

|

(A) |

Power button |

On/Off switch |

|

(B) |

Touch panel |

Use this screen to operate the system. |

|

(C) |

Inlet nozzle (ambient) |

Instrument uses this inlet to sample the particle concentration in the ambient air. |

|

(D) |

Inlet nozzle (sample) |

Instrument uses this inlet to sample the particle concentration inside of the mask. |

|

(E) |

Touch pen |

Use this pen to operate the touch panel (B). |

|

(F) |

Alcohol cartridge |

Contains alcohol that is necessary for measurement |

|

(G) |

USB port (Type B) |

Connects to the PC |

|

(H) |

USB port (Type A) |

Connects to the USB flash drive or the printer |

|

(I) |

LAN port |

Connects to the LAN cable |

|

(J) |

AC jack |

Supplies power from the provided AC adapter |

|

(K) |

Cooling fan |

Maintains correct operating temperature (This cooling fan is to maintain appropriate processing temperatures.) |

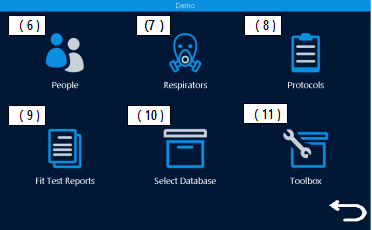

1.2 Software Screen

①Activities

| (1) | Fit Test | Performs mask fit test |

| (2) | Validation Check | Conducts a system check prior to performing series ofmeasurements |

| (3) | Realtime | Displays the fit factor graph and particle concentration ofthe ambient air on a real time basis |

| (4) | Administration | Proceeds to the screen ②(Refer to 5. Administration and Setup for details.) |

| (5) | Setup | Proceeds to the screen ③(Refer to 5. Administration and Setup for details.) |

② Administration

|

(6) |

People | Confirms and selects the list of people being tested.Enters a new person to database |

|

(7) |

Respirators | Confirms and selects the list of respiratorsEnters a new respirator to database |

|

(8) |

Protocols | Confirms and selects the test protocolEnters a new test protocol to database |

|

(9) |

Fit Test Reports | Displays the result of conducted fit tests |

|

(10) |

Select Database | Selects database to load as active |

|

(11) |

Toolbox | Sets the advanced mode |

③ Setup

|

(12) |

Printer Setup | Configures the printer setting |

|

(13) |

Communication | Confirms and sets the internet environment |

|

(14) |

Settings | Configures the setting for the device |

|

(15) |

Date and Time | Edits the date and time setting |

|

(16) |

Touch Screen Calibration | Calibrates the touch screen |

|

(17) |

Device Info | Checks the device information |

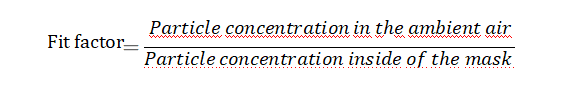

2. Principle of Measurement

2.1 Principle

This device measures particle concentration in the ambient air and inside of the mask, and determines how well a mask fits by comparing the ratio of these particle concentrations. The ratio of the above concentrations is called "fit factor". If the fit factor is 100, it essentially means that the inside of the mask is 100 times as clean as the ambient air.

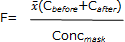

This device measures particle concentration in the ambient air twice in total, before and after a mask fit test exercise. Particle concentration in the ambient air can be variable over time; therefore this device measures the particle concentration in the ambient air before and after each measurement, and uses the average value. The particle concentration in the ambient air must be measured for the first measurement. For the second measurement and subsequent measurements, the concentration after the previous measurement will be used and there is no need for a redundant second measurement of the ambient air.

The sequence would thus be as follows:

Cambient // Cmask // Cambient // Cmask // Cambient …etc.

F: Fit factor

C b e f o r e:Particle concentration in the ambient air before measurement C a f t e r:Particle concentration in the ambient air after measurement C m a s k :Particle concentration inside of the mask

3.1Recharging the Alcohol Cartridge

| Isopropyl alcohol used for this device is a hazardous material. Do not allow the alcohol to contact your eyes and skin.Warning Refer to the Safety Data Sheet (SDS) for chemical material when storing alcohol in a special container and when using it. |

| Recap the alcohol container immediately after use to prevent the alcoholCaution from absorbing moisture and from evaporating. |

The CPC (Condensation Particle Counter) in this device detects particles using isopropyl alcohol vapor. Installing the alcohol cartridge soaked in the alcohol solution to this device will provide the alcohol vapor in the CPC. When the alcohol vapor and an airborne particle come in contact, a droplet which has the particle at its center will be formed. If the alcohol solution in the alcohol cartridge becomes depleted, the device cannot measure particles correctly. To avoid this, please recharge the alcohol cartridge before using the device.

3.1.1 Preparation

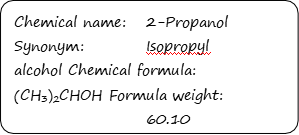

Isopropyl alcohol and the following components are required.

・Alcohol storage container

・Storage cap

・Alcohol cartridge

The isopropyl alcohol used for this device must be a high-purity guaranteed reagent alcohol. Please do not use isopropyl alcohol that is available from pharmacies or supermarkets. The purity of this alcohol is low (about 70%), and may cause damage to the CPC. Any problems caused by a use of alcohol other than specified below is not covered by the warranty.

Please be sure to use the appropriate alcohol with strict adherence to the handling directions.

The alcohol used for this device must be a guaranteed reagent satisfying at least the following requirements:

When the device is not in use, the alcohol cartridge must be stored in the alcohol storage container and the alcohol cartridge inlet must be sealed with the storage cap to keep dust out.

When the device is in use, the storage cap must be used to seal the alcohol storage container.

3.1.2Recharging the Alcohol Cartridge

1. Turn the device off.

2. Open the alcohol storage container by turning the storage cap (or the alcohol cartridge) about 45° counterclockwise.

Stand the storage cap (or the alcohol cartridge) straight up in a clean place.

3.  Pour isopropyl alcohol in the alcohol storage container up to the marked level.

Pour isopropyl alcohol in the alcohol storage container up to the marked level.

Be careful not to tip the bottle and spill the alcohol.

Fill level

4. Insert the alcohol cartridge into the alcohol storage container, and turn it about 45° clockwise until it is firmly locked. Do not use excessive force.

5. After the alcohol cartridge is inserted, the felt in the cartridge will be

soaked in alcohol.You can use the device after a few minutes of soaking the felt in alcohol.

3.1.1 Installing the Alcohol Cartridge

- Remove the alcohol cartridge from the alcohol storage container and gently shake off any excess alcohol solution. Failure to do this may cause the absorbed alcohol to clog the front of the alcohol cartridge. As a result, the flow of the incoming airborne particles and alcohol vapor will be disturbed, making it impossible to measure correctly.

Please wait until the outer surface of the alcohol cartridge dries or wipe the excess alcohol off with a non-abrasive lint- free wipe.

The front of the

Alcohol cartridge

- Insert the alcohol cartridge into the inlet as shown on the right, and turn the alcohol cartridge clockwise about 45°.

To install the alcohol cartridge correctly, be sure to turn it firmly until it stops. (See the picture at right.)

【Caution】

If alcohol accumulates inside the cartridge inlet, wipe the alcohol off with a non-abrasive, lint-free wipe.

・ To prevent the alcohol from absorbing moisture and from evaporating, always recap the alcohol storage container with the storage cap. Contaminated alcohol must be disposed of.

Caution ・ When the device is not in use, the alcohol cartridge must be stored in the alcohol storage container. To keep the inside of the instrument clean, seal the cartridge inlet with the storage cap.

・ Do not carry or store the device with the alcohol cartridge installed. Failure to observe the above may allow the alcohol solution to get into the optical system and affect measurements. When carrying or storing the device, seal the alcohol cartridge inlet with the storage cap to keep dust out.

・Always keep the storage cap and alcohol cartridge clean. (Refer to

6. Maintenance.) If dust sticks to the side of the cartridge or inside of the cap, it may get into the device during operation, affecting measurtement.

・ After measuring for a long period of time, alcohol may accumulate inside the cartridge inlet. If you notice that the measured value of the ambient particle concentration has shifted dramatically check the cartridge inlet, and wipe the accumulated alcohol off with a non-abrasive, lint-free wipe before restarting the device.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.