DRK268 Exhalation Value Air Tightness Tester Operation Manual

Short Description:

Content Safety code Chapter 1 Credit information 1.1 overview 1.2 main features 1.3 main specifications and technical indexes 1.4 working environment and conditions Chapter 2 Structure and working principle 2.1 product structure diagram 2.2 main components 2.3 working principle of the instrument Chapter 3 Key function description Function description of electric control button Chapter 4 Test operation 4.1 check before startup 4.2 detection after startup 4.3 test operation Chapter 5 Common fau...

Content

Safety code

Chapter 1 Credit information

1.1 overview

1.2 main features

1.3 main specifications and technical indexes

1.4 working environment and conditions

Chapter 2 Structure and working principle

2.1 product structure diagram

2.2 main components

2.3 working principle of the instrument

Chapter 3 Key function description

Function description of electric control button

Chapter 4 Test operation

4.1 check before startup

4.2 detection after startup

4.3 test operation

Chapter 5 Common faults and Solutions

Chapter 6 Maintenance of equipment

Safety Code

Warning

At any time, do not open the motherboard with the power plug plugged in.

During the test, the foreign matters shall not be put into the slit

During the test, if the action of any position is abnormal, the test must be stopped to find out the cause of the fault and eliminate it before continuing the test.

In thunderstorm weather, please do not plug and plug the ground wire, power line and other conductors that may be connected with the outside world.

If the power supply is not cut off, do not plug in any live parts and wires.

Non professional or authorized personnel are not allowed to open the product shell.

When the internal parts of the instrument are disassembled, the power line must be pulled off to ensure that the main engine is powered off.

In case of any equipment and personal safety accidents caused by violation of the above warning, all consequences shall be borne by ourselves.

Chapter 1 Product Information

1.1 Overview

It is used to detect the air tightness of the breathing valve of the self-priming filter type anti particle respirator. It is suitable for labor safety protection inspection

Center, occupational safety inspection center, disease prevention and control center, respirator manufacturers, etc.

The instrument has the characteristics of compact structure, complete functions and convenient operation. The instrument adopts single chip microcomputer

Microprocessor control, color touch screen display.

1.2. Main features

1.2.1 high definition color touch screen, easy to operate.

1.2.2 the micro pressure sensor has high sensitivity and is used to collect test data pressure.

1.2.3 high precision gas flowmeter can accurately measure the leakage gas flow of expiratory valve.

Convenient and quick pressure regulating device.

1.3 Main specifications and technical indexes

1.3.1 the buffer capacity shall not be less than 5 liters

1.3.2 range: – 1000pa-0pa, accuracy 1%, resolution 1pA

1.3.3 the pumping speed of vacuum pump is about 2L / min

1.3.4 flow meter range: 0-100ml / min.

1.3.5 power supply: AC220 V, 50 Hz, 150 W

1.3.6 overall dimension: 610 × 600 × 620mm

1.3.7 weight: 30kg

1.4 Working environment and conditions

1.4.1 room temperature control range: 10 ℃~ 35 ℃

1.4.2 relative humidity ≤ 80%

1.4.3 there is no vibration, corrosive medium and strong electromagnetic interference in the surrounding environment.

1.4.4 power supply: AC220 V ± 10% 50 Hz

1.4.5 grounding requirements: the grounding resistance is less than 5 Ω.

Chapter 2 components and working principle

2.1. Main components

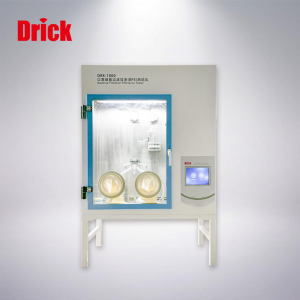

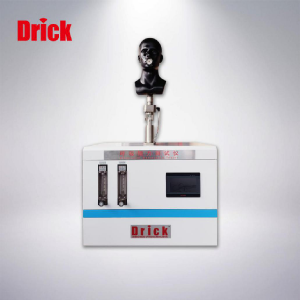

The external structure of the instrument is composed of the instrument shell, test fixture and operation panel; the internal structure of the instrument is composed of pressure control module, CPU data processor, pressure reading device, etc.

2.2 working principle of the instrument

Take appropriate methods (such as using sealant), seal the exhalation valve sample on the exhalation valve test fixture in an airtight manner, open the vacuum pump, adjust the pressure regulating valve, make the exhalation valve bear the pressure of – 249pa, and detect the leakage flow of the exhalation valve.

Chapter 3 test operation

3. Check before startup

3.1.1 check whether the power plug of the host is firmly plugged in.

3.1.2 check that the fixture is installed stably.

3.1.3 check that the flowmeter is installed stably.

3.1.5 check whether the air source is connected and open

3.2 inspection after startup

3.2.1 power on the host.

3.2.2 check whether the color touch screen displays normally, otherwise check whether the circuit is loose.

3.2.3 check whether the instrument has abnormal alarm.

3.3 test operation

The display panel is a color touch screen, and the functions of each key and display screen are as follows:

3.3.1 welcome interface

Click test to enter each interface.

3.3.2 work interface

Key function:

Set: it will stop automatically when the set pressure is reached, and the test failure will be regarded as the final set flow.

[test]: start / stop the test.

Delete: delete the single abnormal data.

[Clear]: used for pressure clearing

Chapter 4. Test procedure:

4.1. Click Set and set the parameters according to the standard.

4.2. Install the sample, seal well, and click test. Adjust the regulating valve to the set value of differential pressure, and the test will stop automatically.

4.3. Data view

Leakage, maximum, minimum, average

4.4. query interface

The buttons [previous] and [next] are used to query the data of the previous group and the next group respectively, and the buttons [previous page and next page] are used to query the corresponding data of the group each time. Press the [Print] key to print all data and statistical data corresponding to the current query group. Press the delete key to delete all data when there is insufficient memory.

Exit to return to the main interface and test to enter the working interface.

Chapter 5. Common faults and Solutions

5.1 the inside of the instrument is abnormal and the pressure cannot rise

Check whether the air pump is loose.

5.2 the pressure value did not change during the experiment

Check if the main board wiring is loose. If it is loose, plug it in firmly

Check whether the flowmeter is turned on.

5.3 there are big differences in experimental data

Please contact the manufacturer for guidance and correction.

Chapter 6 maintenance of equipment

6.1 keep the equipment and control system clean and sanitary.

6.2 prevent high temperature, excessive humidity, dust, corrosive media, water, etc. from getting into the machine or control system.

6.3 check regularly to keep the integrity of parts and components.

6.4 the pressure indication value of the instrument has been calibrated before leaving the factory. Non professional verification and maintenance personnel are not allowed to calibrate arbitrarily, otherwise, the force measurement of the instrument will be inaccurate.

6.5 do a good job of instrument calibration regularly to ensure the accuracy of instrument measurement value.

6.6 non professional maintenance and verification personnel are not allowed to remove the instrument, and measurement performance verification must be carried out after each repair to avoid instrument misalignment.

6.7 the company will not be responsible for any loss caused by the modification of the machine without the consent of the company during the use of the machine.

6.8 the company will not be responsible for all consequences caused by the operation not in accordance with the precautions and requirements of the manual.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.