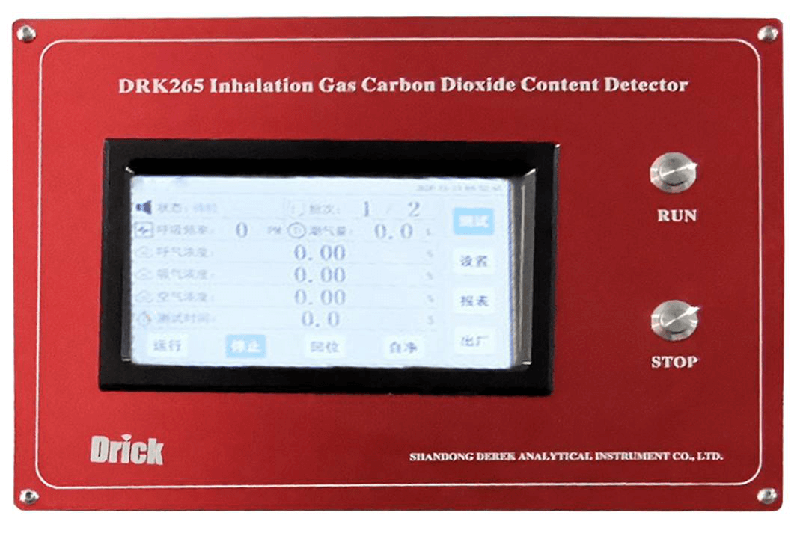

DRK265 Inhalation Gas Carbon Dioxide Content Detector

Short Description:

1 Introduction This product is used to test the dead chamber of positive pressure air respirator. It is designed and manufactured according to the standard ga124 and gb2890. The test device mainly includes: test head mold, artificial simulation respirator, connecting pipe, flowmeter, CO2 gas analyzer and control system. The test principle is to determine the CO2 content in the inhaled gas. Applicable standards: ga124-2013 positive pressure air breathing apparatus for fire protection, article ...

Content

1 Introduction..................................................................................................................- 1 -

2 Safety regulations.........................................................................................................- 1 -

3 Technical specifications...............................................................................................- 1 -

4 Installation....................................................................................................................- 2 -

5 Operation......................................................................................................................- 2 -

6 Touch Screen Operation..............................................................................................- 3 -

7 Operation method.........................................................................................................- 7 -

8 Maintenance..................................................................................................................- 7 -

1 Introduction

This product is used to test the dead chamber of positive pressure air respirator. It is designed and manufactured according to the standard ga124 and gb2890. The test device mainly includes: test head mold, artificial simulation respirator, connecting pipe, flowmeter, CO2 gas analyzer and control system. The test principle is to determine the CO2 content in the inhaled gas. Applicable standards: ga124-2013 positive pressure air breathing apparatus for fire protection, article 6.13.3 determination of carbon dioxide content in inhaled gas; gb2890-2009 breathing protection self-priming filter gas mask, chapter 6.7 dead chamber test of face mask; GB 21976.7-2012 escape and refuge equipment for building fire Part 7: Test of filtered self rescue breathing apparatus for fire fighting;

Dead space: the volume of gas re inhaled in the previous exhalation, the test result should not be greater than 1%;

This manual contains the operation steps and safety precautions! Please read carefully before installing and operating your instrument to ensure safe use and accurate test results.

2 Safety regulations

2.1 Safety

This chapter introduces the manual before use. Please read and understand all the precautions.

2.2 Emergency power failure

In case of emergency, you can unplug the plug power supply, disconnect all power supplies and stop the test.

3 Technical specifications

Display and control: color touch screen display and operation, parallel metal key operation;

Working environment: the concentration of CO2 in the surrounding air is ≤ 0.1%;

CO2 source: volume fraction of CO2 (5 ± 0.1)%;

CO2 mixing flow rate: > 0-40l / min, accuracy: grade 2.5;

CO2 sensor: range 0-20%, range 0-5%; accuracy level 1;

Floor mounted electric fan.

Simulated respiratory rate regulation: (1-25) times / min, respiratory tidal volume regulation (0.5-2.0) L;

Test data: automatic storage or printing;

External dimension (L × w × h): About 1000mm × 650mm × 1300mm;

Power supply: AC220 V, 50 Hz, 900 W;

Weight: About 70kg;

4 Installation

Unpacking of instruments

When you receive the equipment, please check whether the wooden case is damaged during transportation; carefully open the packing box of the equipment and thoroughly check whether the parts are damaged. Please report the equipment damage to the carrier or the customer service department of our company.

5 Operation

5.1 Schematic diagram of the whole machine

5.2 Control panel

6 Touch screen operation

This chapter introduces the functions and basic usage of the touch screen. Please familiarize yourself with the touch screen according to the instructions in this chapter before operation.

6.1 Startup interface: turn on the power switch of the instrument, and the screen will display the boot interface as shown in the figure;

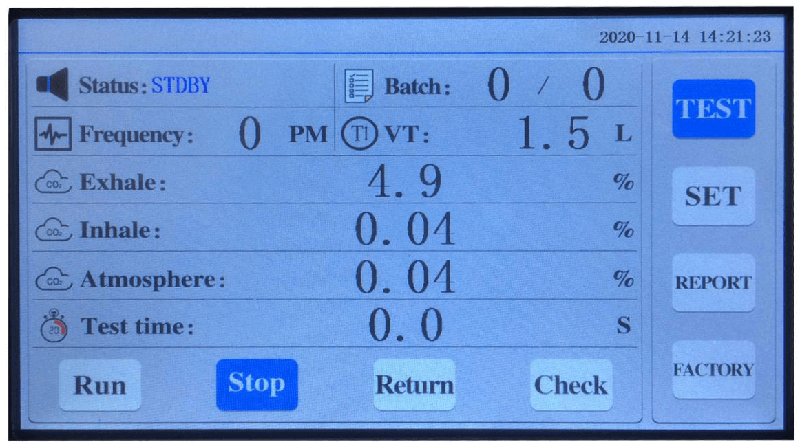

6.2 Start up interface: it will automatically enter the startup test interface after startup, as shown in the figure;

[Status]: display the current machine running status;

[Frequencye]: display the respiratory rate of simulated respirator;

[Exhale]: displays the exhaled carbon dioxide concentration of the simulated respirator;

[Inhale]: displays the concentration of carbon dioxide inhaled by the simulated respirator;

[Atmosphere]: display the ambient carbon dioxide concentration;

[Test time]: display the sample test time;

[Batch]: display the current test batch and times;

[VT]: display the tidal exhaled volume of simulated respirator;

[Run]: start the test run;

[Stop]: stop the test;

[Return]: the respirator returns to its original position;

[Check]: air concentration calibration test;

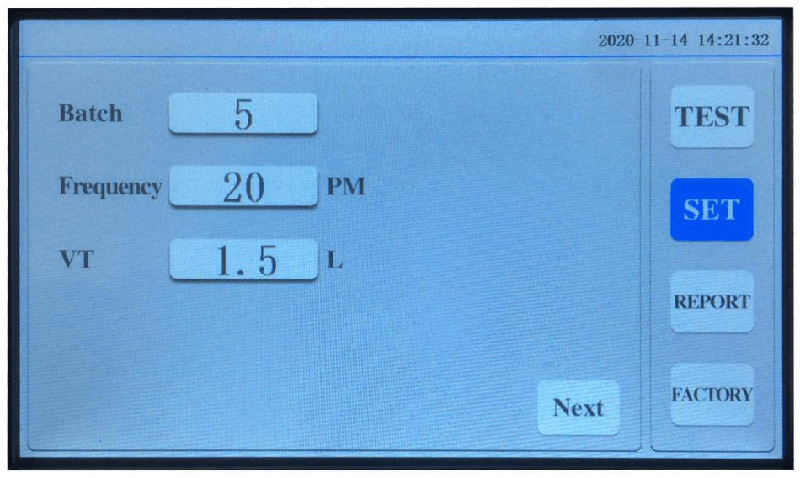

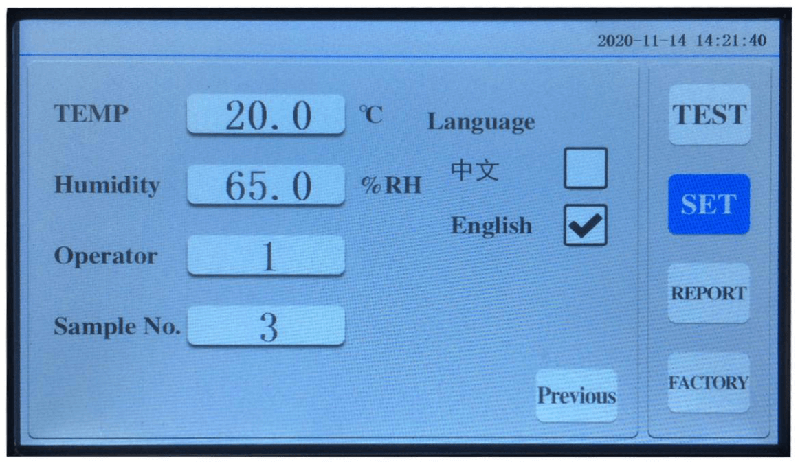

6.3 Setting interface

[Batch]: set the test batch of the test sample;

[Frequencye]]: simulate the respiratory rate setting of respirator;

[VT]]: simulate the tidal volume setting of respirator;

[Next]: parameter setting on the next page;

[TEMP]: 0-100%;

[Humidity]: the temperature of the experimental environment, ranging from 0 ℃ to 100 ℃;

[Operator.]: the number of the test personnel, which can be customized;

[Sample No.]: it represents the name and number of your experiment, which can be drawn up by yourself;

[Language]: switch between Chinese and English;

[Previous]: return to the previous page;

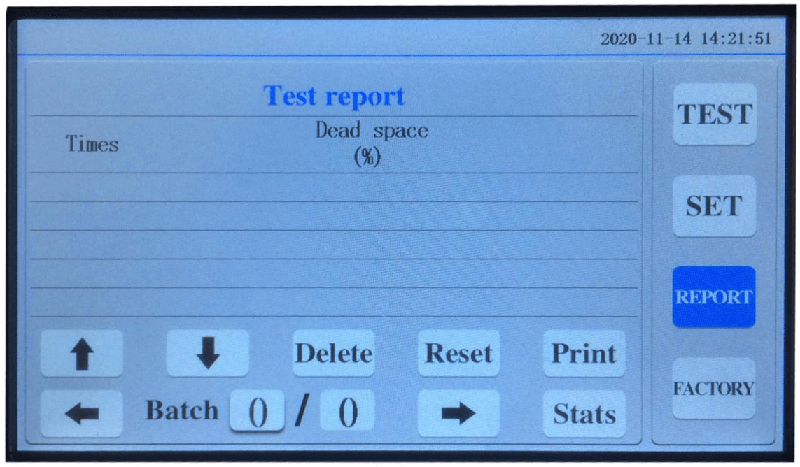

6.4 Report interface

[Delete]: delete the currently selected test result, and red is selected;

[Reset]: reset to clear all test data of current test;

[Print]: print the current test data;

[Stats]: the maximum and minimum average of the test data shall be counted by batch;

[↑↓←→]: test data page turning batch query;

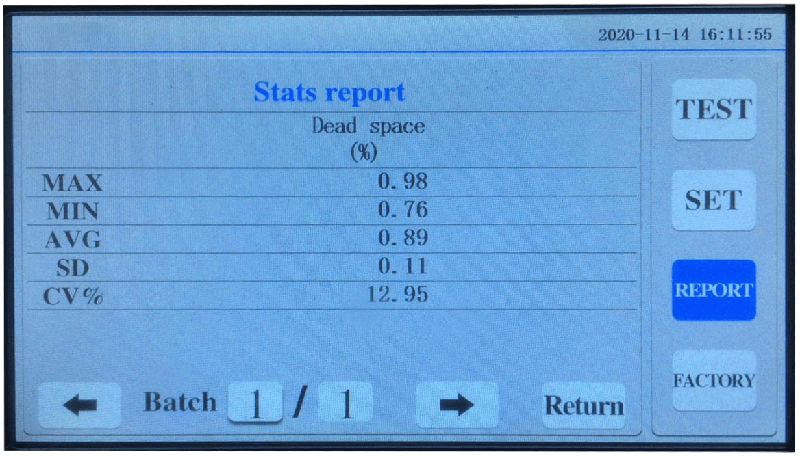

6.5 [Statistical report] statistical report page

[MAX]: the maximum value in the test batch data;

[MIN]: the minimum value in the test batch data;

[AVG]: the average value of data within the test batch;

[SD]: mean square deviation of pressure of current batch;

[CV%]: CV value of current batch pressure;

[Return]: return to the previous page;

6.8 [Factory]: system parameter setting, need password to enter;

7 Operation method

1. Place the instrument in the environment required by the standard, connect the power supply to the power socket with protective ground wire, and turn on the power switch of the instrument;

2. Carbon dioxide gas source (CO2) access: prepare carbon dioxide gas (CO2) and gas cylinder according to the standard, connect the pressure reducing valve, and then connect the gas pipe with the equipment;

3. Connect the communication line of the air concentration sensor with the host machine, and place the air concentration sensor about 1 meter away from the sample head mold;

4. According to the test requirements, the respiratory rate, tidal volume and other test parameters are set in the setting interface;

5. Click return in the test interface to display the instrument status as standby (other operations can only be performed in standby mode);

6. Click calibration in the test interface to observe the display of expiratory concentration in the test interface; adjust the expiratory regulating valve until the expiratory concentration on the test interface is displayed at 5% or other standard value, so that the expiratory concentration display is stable, then click stop;

7. Click return to make the working state of the instrument display standby. Put the mask on the test head mold correctly. The mask should be sealed well without deformation. If necessary, the mask can be sealed with PVC tape or other suitable sealant and putty to ensure the good sealing of the sample;

8. Check the setting parameters, adjust the simulated respirator to the respiratory rate of 25 times / min and the respiratory tidal volume to 2L / time;

9. Click the run button on the display screen or on the panel to continuously measure and record the carbon dioxide (CO2) content in the inhaled gas; when the inspiratory concentration and air concentration test are in a stable state, the test will be stopped automatically and the CO2 content in the inhaled gas will be recorded at the same time. (the CO2 content in the inhaled gas minus the air concentration in the environment is the CO2 content in the inhaled gas. The sample should be tested three times and the average value should be less than 1%)

8 Maintenance

1. After the experiment, please turn off the power supply and CO2 source of the instrument;

2. Clean the breathing mouth of the head mold without dust;

3. Keep the instrument table clean and do not pile up other sundries;

4. When using the expiratory concentration control valve, please adjust it slightly, and do not adjust it too much (the exhaled concentration display should meet the standard concentration);

5. After each operation test is completed, please click return to make the status standby before continuing other operations;

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.