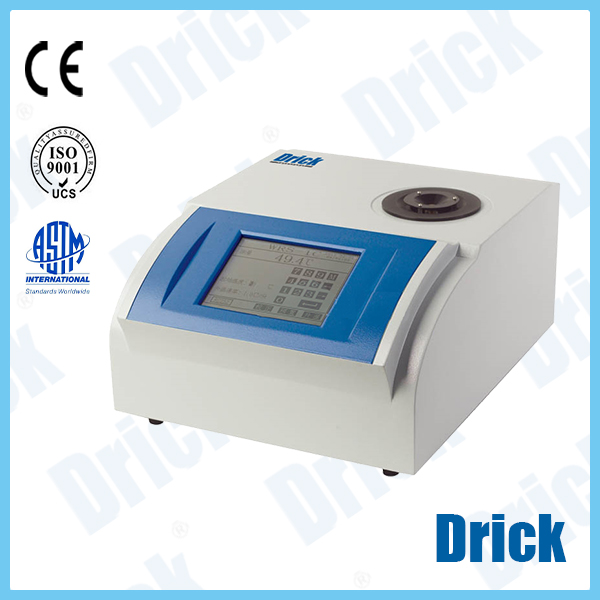

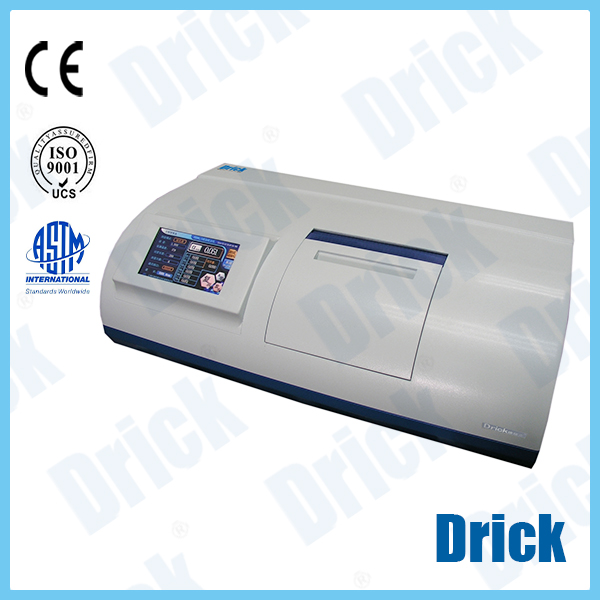

DRK119B Touch Screen Softness Tester

Short Description:

Product Introduction DRK119B Touch screen softness tester is a new type of high-precision intelligent instrument which is designed and produced according to the relevant national and international standards. Modern mechanical design and microcomputer processing technology has been used. It uses advanced components, supporting components and a single-chip microcomputer for reasonable construction and multi-functional design. It has Chinese and English display and a variety of parameters incl...

DRK119B Touch Screen Softness Tester Detail:

Product Introduction

DRK119B Touch screen softness tester is a new type of high-precision intelligent instrument which is designed and produced according to the relevant national and international standards. Modern mechanical design and microcomputer processing technology has been used. It uses advanced components, supporting components and a single-chip microcomputer for reasonable construction and multi-functional design. It has Chinese and English display and a variety of parameters included in the standard test, conversion, adjustment, display, memory, printing and other functions.

Product Features

1. High-precision load cell has used to ensure the test accuracy error is within ±1%. Better than ±3% of the standard.

2. Using stepper motor control, the probe travel process is accurate and stable, and the measurement results are reproducible.

3. Touch screen Chinese and English display, User friendly interface operation, fully automatic test, with test data statistical processing function, micro printer output.

4. The test results are automatically stored and displayed, reducing human error, making it easy to operate and making the results stable and correct. Single measurement result can be stored

5. Statistical analysis functions such as mean value, standard deviation, maximum/minimum also available

6. Before starting the test, it will zero clearing automatically.

7.RS-232 output interface available

Product Applications

The instrument is applicable for the softness test of high-grade toilet paper, tobacco sheet, non-woven fabrics, sanitary towel, Kleenex, film, textile, and scrim and so on. Also helpful to evaluate the physical properties of semi-finished products and final products.

Technical Standard

- GB/T8942 Paper Softness Testing Method

- TAPPI T 498 cm-85: Softness for toilet paper

- IST 90-3(95) Standard Handle-o-meter Stiffness Testing Method for Non-woven Fabrics

Product Parameters

|

Items |

Parameters |

|

Test Range |

10 ~ 1000mN |

|

Resolution |

0.01mN |

|

Indication Error |

±1%(Below full scale’s 20%, the error allowed > 1mN) |

|

Indication Repeat Error |

<3%(Below full scale’s 20%, the error allowed > 1mN) |

|

Probe Total Trip |

12±0.5mm |

|

Probe Indentation Depth |

8~8.5mm |

|

Platform Slit Width |

5mm, 6.35 mm, 10 mm, 20 mm (±0.05mm) |

|

Platform Slit Parallel Error |

≤0.05mm |

|

Probe Neutral Error |

≤0.05mm |

|

Power supply |

AC 220V±5% |

|

Instrument Size |

240mm×300mm×280mm |

|

Weight |

24kg |

Main Fixtures

Mainframe

A Power line

Operating manual

Certificate of quality

Four round printed paper

Softness Tester has a wide range of applications in many industries, mainly including but not limited to the following aspects:

1. Textile industry:

Softness tester is used in the textile industry to measure the softness of textile D products, such as blankets, towels, bedding and so on. The softness of textile really affects its comfort and performance, so the softness tester has become an important tool for textile quality inspection.

2. Leather industry:

The softness of leather products is one of the important indexes of its quality. The softness tester can be used to measure the softness of leather shoes, leather bags, leather clothing and other leather products, which provides important quality assurance for the production of leather products.

3. Rubber industry:

The softness of rubber products has an important influence on its performance. In automotive tires, seals and other fields, the softness of rubber is directly related to its sealing and service life. The application of softness tester is helpful to accurately evaluate the softness properties of rubber products.

4. plastic industry:

The softness of plastic products has an important impact on its use effect and safety. In the fields of packaging materials, pipes, wires and cables, softness testers can be used to measure and evaluate the softness properties of plastic products.

5. Paper industry:

Paper softness tester is an instrument specially used to measure the softness of paper. In the paper industry, softness tester help manufacturers understand and optimize the softness characteristics of products to meet the needs of different consumers.

Product detail pictures:

Related Product Guide:

Why and How to Choose a Suitable Shock Test Machine

Points To Consider While Choosing Lab Testing Machines for Your Industrial Laboratory

To meet the customers' over-expected gratification , we have our robust crew to offer our best over-all support which includes marketing, income, coming up with, production, excellent managing, packing, warehousing and logistics for DRK119B Touch Screen Softness Tester, The product will supply to all over the world, such as: Spain, Ghana, Guatemala, We follow up the career and aspiration of our elder generation, and we're eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have now a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.