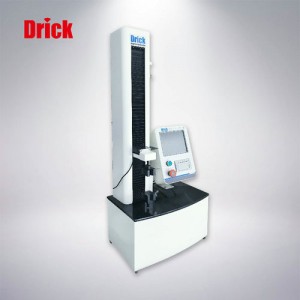

DRK Plastic Runway Impact Absorption Tester

Short Description:

DRK plastic runway impact absorption testing machine is mainly used for the determination of plastic sports venues and impact absorption performance. The heavy hammer of the instrument simulates the effect of human body to impact the synthetic surface layer, and the test results are calculated by computer. The instrument has strong test ability, flexible and convenient movement, and is convenient for testing in various environments. The test precision is high and the data repeatability is goo...

DRK plastic runway impact absorption testing machine is mainly used for the determination of plastic sports venues and impact absorption performance. The heavy hammer of the instrument simulates the effect of human body to impact the synthetic surface layer, and the test results are calculated by computer. The instrument has strong test ability, flexible and convenient movement, and is convenient for testing in various environments. The test precision is high and the data repeatability is good.

Features:

1. The instrument is flexible and convenient to move, which is convenient for experiments in various environments;

2. Satisfied with the “shock absorption” test method in the test standards of many sports venues at home and abroad;

3. High precision and good data repeatability, using high-precision pressure sensor, the test force value is accurate and stable;

4. Adopt system clock circuit design, hard double buffering to realize continuous acquisition and storage and increase system anti-interference design;

5. The test efficiency is high, the number of tests completed in 60S, the impact absorption test (4 times), the vertical deformation test (3 times);

6. Using professional computer operation, industrial touch screen computer, the configuration and stability are much higher than the touch screen terminals in the general sense;

7. Equipped with rich software interactive interface, the multi-language environment can satisfy users from different countries and regions.

Applications:

DRK plastic runway impact absorption testing machine mainly tests the impact absorption performance and vertical deformation performance of plastic sports venues.

Technical standard

EN14808-2003 “Determination method for impact absorption of sports ground floor”

GB 36246-2018 “Sports Fields with Synthetic Surfaces for Primary and Secondary Schools”

GB/T14833-2011 “Synthetic material runway surface”

GB/T22517.6-2011 “Sports venue use requirements and inspection methods”

GB/T19851.11-2005 “Sports equipment and venues for primary and secondary schools – Part 11 Sports venues with synthetic material surfaces”

GB/T19995.2-2005 “Requirements and inspection methods for the use of natural material sports venues Part 2: Wooden floor venues for comprehensive sports venues”

Product parameters:

1. Drop hammer weight: 20Kg±0.1Kg

2. Drop hammer height: 55±0.25mm

3. Hammer drop frequency: 60S to complete the complete impact

4. Shock absorption test: 4 times

5. Hammer lifting method: electric/manual

6. Positioning method: automatic dynamic zero alignment

7. Spring stiffness: 2000±60N/mm

8. Spring material: 70Si3MnA spring steel

9. Force measurement: 6600N±2%

10. Deformation measurement: ±10±0.05mm

11. Deformation acquisition: measurement range ±10mm, measurement accuracy 0.02mm, acquisition frequency higher than 2kHz

12. Zero point accuracy: ±0.025mm

13. Force value acquisition: 50~15kN±50N

14. Acquisition frequency: higher than 2kHz

15. Control method: PC touch screen all-in-one machine

16. Reporting method: automatic printing of A4 standard test report

17. Force value acquisition frequency: greater than 1kHz

18. Deformation acquisition frequency: greater than 1kHz

19. Lifting hammer height accuracy: ±0.02mm

20. Comprehensive precision of lifting hammer: ±0.05mm

21. Helical spring diameter: 69±1.0mm

22. Power supply: AC220v 50Hz 500w

Note: The information will be changed due to technological progress without prior notice, and the actual product shall prevail.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.