DRK-07B Respirator Flame Retardant Tester Operation Manual

Short Description:

Safety warning Dear users Please note that the following items may be involved in the process of using the instrument: 1、 Please be sure to read the relevant standards and equipment instructions before using the equipment 2、 The observation window must be closed when the test is in progress! 3、 When the specified voltage is used, the instrument power should be grounded. 4、 Inflammable and explosive materials other than those required for the test are strictly prohibited in the laboratory!...

Safety warning

Dear users

Please note that the following items may be involved in the process of using the instrument:

1、 Please be sure to read the relevant standards and equipment instructions before using the equipment

2、 The observation window must be closed when the test is in progress!

3、 When the specified voltage is used, the instrument power should be grounded.

4、 Inflammable and explosive materials other than those required for the test are strictly prohibited in the laboratory!

5、 The operator shall not leave the test site.

6、 The laboratory shall be equipped with fire fighting equipment.

7、 At the end of the test, all power and air sources should be turned off. Please be sure to clean the test residue or droppings!

Overview

The flame retardant tester for respirator is developed according to gb2626 respiratory protective equipment, which is used to test the fire resistance and flame retardant performance of respirators. The applicable standards are: gb2626 respiratory protective articles, gb19082 technical requirements for disposable medical protective clothing, gb19083 technical requirements for medical protective masks, and gb32610 technical specification for daily protective masks Yy0469 medical surgical mask, yyt0969 disposable medical mask, etc.

Technical parameters

1. The mask head mold is made of metal material, and the facial features are simulated according to the ratio of 1:1

2. PLC touch screen + PLC control, to achieve control / detection / calculation / data display / historical data query multi-function

3. Touch screen:

a. Size: 7 "effective display size: 15.41cm long and 8.59cm wide;

b. Resolution: 480 * 480

c. Communication interface: RS232, 3.3V CMOS or TTL, serial port mode

d. Storage capacity: 1g

e. Using pure hardware FPGA drive display, "zero" start-up time, power on can run

f. Using m3 + FPGA architecture, m3 is responsible for instruction parsing, FPGA focuses on TFT display to ensure speed and reliability

4. The burner height can be adjusted

5. Automatic positioning and timing

6. Display the afterburning time

7. Equipped with flame sensor

8. Head mold movement speed (60 ± 5) mm / s

9. The diameter of flame temperature probe is 1.5mm

10. Flame temperature adjustment range: 750-950 ℃

11. The accuracy of afterburning time is 0.1s

12. Power supply: 220 V, 50 Hz

13. Gas: propane or LPG

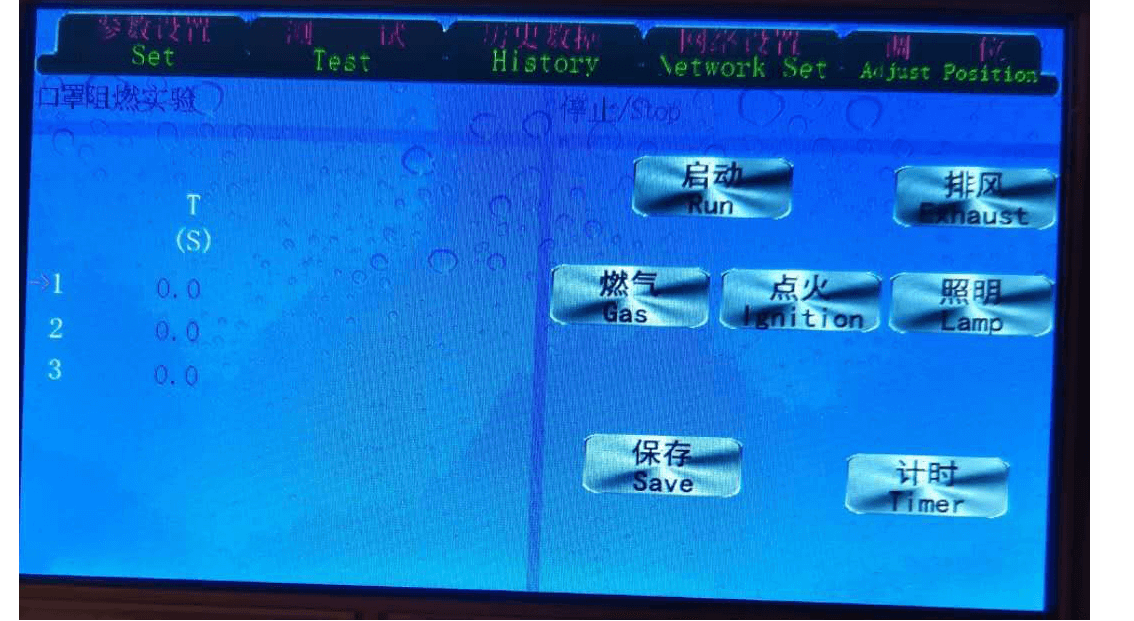

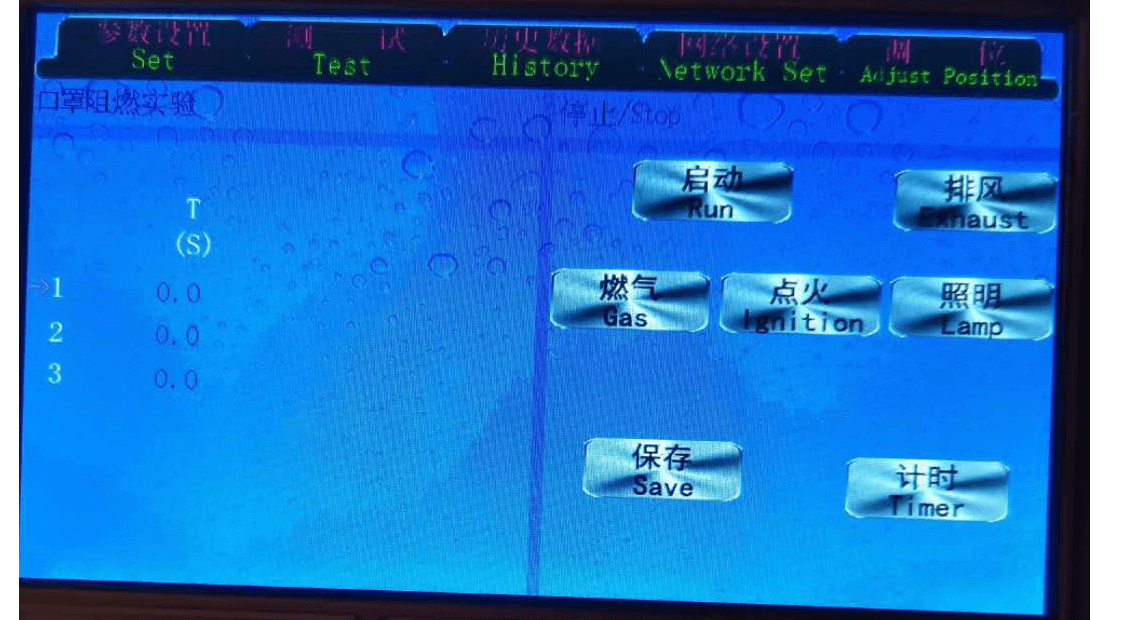

Introduction to operation interface

Test interface:

1.Click directly to the top of the lamp to adjust the distance from the nozzle to the lower die

2. Start: the head mold starts to move towards the blowtorch direction and stops at another position through the blowtorch

3. Exhaust: turn on / off the exhaust fan on the box →

4. Gas: open / close gas channel

5. Ignition: start the high pressure ignition device

6. Lighting: turn on / off the lamp in the box

7. Save: save the test data after the test

8. Timing: record the afterburning time

Usage method

Tips: please read the relevant test standards carefully before using the equipment!

1. Connect the power supply and air source behind the box

2. Turn on the power and push up the knob on the front panel (the position is shown in the figure below)

After power on, enter the test interface

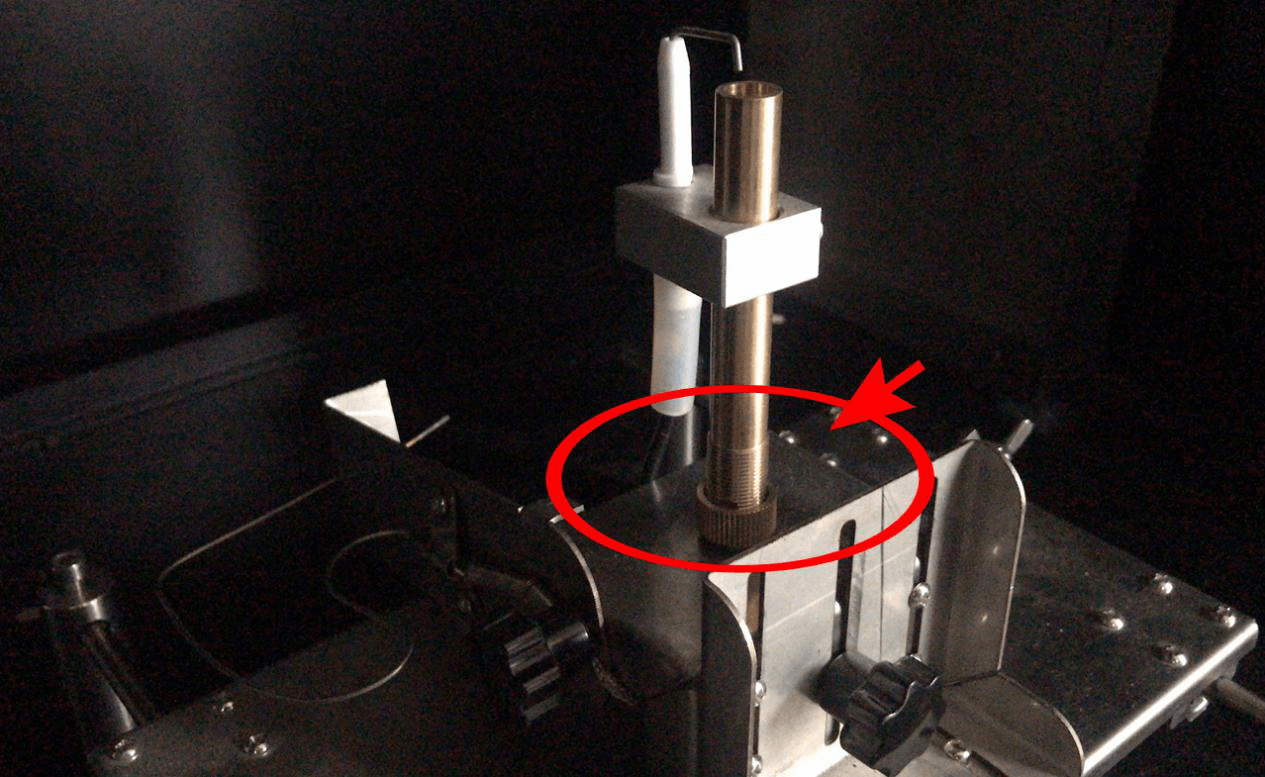

a. First, click the position adjustment button, and the head mold starts to move. When the head mold senses the flame position sensor, the head mold stops moving; at this time, manually adjust the distance between the blowtorch and the lower end of the mask to 20 mm, and then fix the position of the blowtorch.

b. Adjust the position of blowtorch and then click start to reset the headform

c. After the head mold is reset, press the gas button to turn on the gas, and then press the ignition button. The igniter will ignite three times. If it is not lit, press the ignition button again

d. point the burner and adjust the gas flow knob on the panel to make the flame height 40 + 4mm.

e. After adjusting the flame height, the temperature sensor is used to measure the temperature at 20 ± 2mm on the blowtorch. The flame temperature is adjusted to 800 ± 50 ℃ by adjusting the nut at the lower end of the burner (the position is shown in the figure below) with air

f. After adjusting the temperature, remove the temperature sensor, click the start button, and the head mold starts to move like the other end

g. When the flame position sensor detects the head mold, the afterburning time is automatically timed. When the continuous combustion (total time of flaming and flameless combustion) of the mask is extinguished, click the timing button to stop timing

h. You can make three patterns in succession, and then click the Save button to save the data

Other

1. The saved data can be queried in the historical data

2. During the test, the lamp can be turned on or off as required

3. After the test, turn on the exhaust air to exhaust the combustion waste gas from the box

4. Whether the test results are qualified can be compared according to relevant standards or regulations

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.