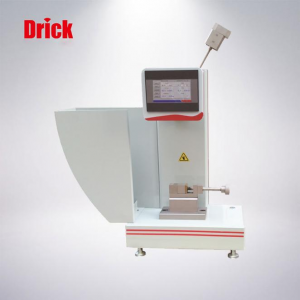

Charpy Impact Testing Machine DRK-J5M

Short Description:

DRK-J5M Charpy Impact Testing Machine This testing machine is mainly used for determining the impact toughness of non-metallic materials such as hard plastics (including plates, pipes, plastic profiles), reinforced nylon, fiberglass, ceramics, cast stones, and electrical insulation materials. Widely used in the chemical industry, scientific research institutions, and quality inspection departments of colleges and universities. This instrument is a simple structure, easy operation, and accur...

DRK-J5M Charpy Impact Testing Machine

This testing machine is mainly used for determining the impact toughness of non-metallic materials such as hard plastics (including plates, pipes, plastic profiles), reinforced nylon, fiberglass, ceramics, cast stones, and electrical insulation materials. Widely used in the chemical industry, scientific research institutions, and quality inspection departments of colleges and universities.

This instrument is a simple structure, easy operation, and accurate and reliable data impact testing machine. Please read this instruction carefully before use.

This instrument is equipped with a 7-inch full-color touch screen, which can input the size of the sample, calculate the impact strength and save the data based on the automatically collected energy loss value. The machine is equipped with a USB output port, which can directly export data through a USB flash drive and open it directly on a PC for editing and printing experimental reports.

Working principle:

Strike the sample supported as a horizontal beam with a pendulum of known energy, and the sample is destroyed by one impact of the pendulum. The impact line is located in the center of the two supports, and the energy difference between the pendulum before and after impact is used to determine the energy absorbed by the specimen during failure. Then calculate the impact strength based on the original cross-sectional area of the sample.

Product features:

Never exceed the quality limit

The instrument adopts high hardness and high-precision bearings, and uses shaftless photoelectric sensors to fundamentally eliminate the losses caused by friction, ensuring that the frictional energy loss is far less than the standard requirements.

Intelligent prompt

Based on the impact situation, intelligent prompts indicate the working status and interact with the experimenter at all times, ensuring the success rate of the experiment.

Test standards:

ISO179、GB/T1043、GB/T2611

Product parameters:

Impact velocity: 2.9m/s;

Impact energy: 1J, 2J, 4J, 5J (2J, 4J, 5J are one hammer);

Maximum frictional loss energy:<0.5%;

Pre swing angle of pendulum: 150 ± 1 °;

Strike center distance: 230mm;

Jaw spacing: 60mm 70mm 62mm 95mm;

Round corner of impact blade: R2mm ± 0.5mm;

Angle measurement accuracy: 1 point;

Accuracy: 0.05% of the displayed value;

Energy units: J, kgmm, kgcm, kgm, lbft, lbin are interchangeable;

Temperature: -10 ℃ to 40 ℃;

Power supply: 220VAC-15%~220VAC+10%, 50Hz (single-phase three wire system).

Note: Due to technological progress, information may be changed without prior notice. The actual product in the future shall prevail.

SHANDONG DRICK INSTRUMENTS CO.,LTD

Company Profile

Shandong Drick Instruments Co., Ltd, is mainly engaged in the research and development, manufacturing and sales of testing instruments.

The company established in 2004.

Products are used in scientific research units, quality inspection institutions, universities, packaging, paper, printing, rubber and plastics, chemicals, food, pharmaceuticals, textiles, and other industries.

Drick pays attention to talent cultivation and team building, adhering to the development concept of professionalism, dedication.pragmatism, and innovation.

Adhering to the customer-oriented principle, solve the most urgent and practical needs of customers, and provide first-class solutions to customers with high-quality products and advanced technology.